Abstract

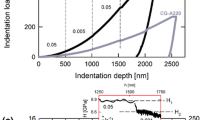

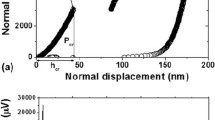

Strain-rate sensitivity (SRS) measurements using transient small-scale techniques are becoming increasingly popular for investigating nanostructured films and microcomponents since they can provide fundamental insights into the plastic deformation mechanisms within small volumes of material. Previously, researchers have typically used either nanoindentation or microcompression strain-rate jump tests on a variety of nanostructured materials and compared the resultant values with bulk compression data as a reference. However, no systematic comparison of the different transient micromechanical techniques has been performed on the same material to establish their relative merits or the consistency of their results. In this study, the SRS of nanocrystalline nickel is investigated using three independent, in situ, transient experimental techniques: miniature tension, nanoindentation, and micropillar compression. The obtained SRS exponents m measured by all techniques were found to be in good agreement, and the resulting apparent activation volume V app of approximately 10 b 3 is consistent with grain boundary diffusion processes and dislocation glide-based plasticity.

Similar content being viewed by others

References

M.A. Meyers, A. Mishra, and D.J. Benson, Prog. Mater. Sci. 51, 427 (2006).

L. Wang and B.C. Prorok, J. Mater. Res. 23, 55 (2011).

K.S. Kumar, H. Van Swygenhoven, and S. Suresh, Acta Mater. 51, 5743 (2003).

G. Palumbo, S.J. Thorpe, and K.T. Aust, Scripta Metall. Mater. 24, 1347 (1990).

N. Wang, Z. Wang, K.T. Aust, and U. Erb, Acta Metall. Mater. 43, 519 (1995).

N.Q. Chinh, P. Szommer, Z. Horita, and T.G. Langdon, Adv. Mater. 18, 34 (2006).

H. Van Swygenhoven, Mater. Sci. Eng. A 483–484, 33 (2008).

R.L. Coble, J. Appl. Phys. 34, 1679 (1963).

T. Langdon, J. Mater. Sci. 41, 597 (2006).

R. Valiev, Nat. Mater. 3, 511 (2004).

F. Dalla Torre, H. Van Swygenhoven, and M. Victoria, Acta Mater. 50, 3957 (2002).

Y.F. Shen, L. Lu, Q.H. Lu, Z.H. **, and K. Lu, Scripta Mater. 52, 989 (2005).

E. Ma, Y.M. Wang, Q.H. Lu, M.L. Sui, L. Lu, and K. Lu, Appl. Phys. Lett. 85, 4932 (2004).

Y.M. Wang and E. Ma, Mater. Sci. Eng. A 375–377, 46 (2004).

J.-Y. Kim and J.R. Greer, Acta Mater. 57, 5245 (2009).

Y. Wang, A. Hamza, and E. Ma, Acta Mater. 54, 2715 (2006).

N. Karanjgaokar, K. Jonnalagadda, I. Chasiotis, J. Chee, A. Mahmood, and D. Peroulis, Paper presented at the Proceedings XIth International Congress and Exposition (Orlando, FL, 2008).

K.N. Jonnalagadda, I. Chasiotis, S. Yagnamurthy, J. Lambros, J. Pulskamp, R. Polcawich, and M. Dubey, Exp. Mech. 50, 25 (2009).

D.S. Gianola, D.H. Warner, J.F. Molinari, and K.J. Hemker, Scripta Mater. 55, 649 (2006).

Q. Wei, S. Cheng, K. Ramesh, and E. Ma, Mater. Sci. Eng. A 381, 71 (2004).

M.J. Mayo and W.D. Nix, Acta Metall. 36, 2183 (1988).

R. Schwaiger, B. Moser, M. Dao, N. Chollacoop, and S. Suresh, Acta Mater. 51, 5159 (2003).

D. Pan and M.W. Chen, J. Mater. Res. 24, 1466 (2011).

V. Maier, K. Durst, and J. Mueller, J. Mater. Res. 28, 1421 (2011).

J.M. Wheeler, V. Maier, K. Durst, M. Göken, and J. Michler, Mater. Sci. Eng. A 585, 108 (2013).

V. Maier, C. Schunk, M. Göken, and K. Durst, Philos. Mag. 1–14 (2014).

M. Uchic, D. Dimiduk, J. Florando, and W. Nix, Science 305, 986 (2004).

D. Kiener, W. Grosinger, G. Dehm, and R. Pippan, Acta Mater. 56, 580 (2008).

J.M. Wheeler, C. Niederberger, C. Tessarek, S. Christiansen, and J. Michler, Int. J. Plast. 40, 140 (2013).

J.S. Carpenter, A. Misra, M.D. Uchic, and P.M. Anderson, Appl. Phys. Lett. 101, 051901 (2012).

G. Mohanty, J.M. Wheeler, R. Raghavan, J. Wehrs, M. Hasegawa, S. Mischler, L. Philippe, and J. Michler, Philos. Mag. 1–18 (2014).

V. Saile, LIGA Appl. 7, 1 (2009).

T.J. Rupert, J.C. Trenkle, and C.A. Schuh, Acta Mater. 59, 1619 (2011).

J.R. Trelewicz and C.A. Schuh, Acta Mater. 55, 5948 (2007).

A. Detor and C. Schuh, Acta Mater. 55, 371 (2007).

W.M. Yin, S.H. Whang, R. Mirshams, and C.H. **ao, Mater. Sci. Eng. A 301, 18 (2001).

W.M. Yin and S.H. Whang, Scripta Mater. 44, 569 (2001).

W.M. Yin, S.H. Whang, and R.A. Mirshams, Acta Mater. 53, 383 (2005).

Y.M. Wang, S. Cheng, Q.M. Wei, E. Ma, T.G. Nieh, and A. Hamza, Scripta Mater. 51, 1023 (2004).

C.S. Barret and T.B. Massalski, Structure of Metals (Oxford: Pergamon Press, 1980).

P. Scherrer, Nachrichten von Der Gesellschaft Der Wissenschaften 98–100 (1918).

J. Langford and A. Wilson, J. Appl. Crystallogr. 11, 102–113 (1978).

L.A. Giannuzzi and F.A. Stevie, Micron 30, 197 (1999).

L. Philippe, P. Schwaller, G. Bürki, and J. Michler, J. Mater. Res. 23, 1383 (2011).

B. Lucas and T. Kanade, IJCAI 121–130 (1981).

R. Rabe, J.M. Breguet, P. Schwaller, S. Stauss, F.J. Haug, and J. Patscheider, Thin Solid Films 469–470, 206 (2004).

J.M. Wheeler, P. Brodard, and J. Michler, Philos. Mag. 92, 3128 (2012).

W.C. Oliver and G.M. Pharr, J. Mater. Res. 7, 1564 (1992).

S.A.S. Asif, K.J. Wahl, and R.J. Colton, Rev. Sci. Instrum. 70, 2408 (1999).

W. Oliver and G. Pharr, J. Mater. Res. 19, 3 (2004).

B.N. Lucas and W.C. Oliver, Metall. Mater. Trans. A 30, 601 (1999).

D. Caillard and J.L. Martin, Pergamon Mater. Ser. 8, 3 (2003).

G.E. Dieter and D. Bacon, Mechanical Metallurgy (New York: McGraw-Hill, 1986), p. 751.

F.F. Csikor, C. Motz, D. Weygand, M. Zaiser, and S. Zapperi, Science 318, 251 (2007).

E. Hart, Acta Metall. 15, 351 (1967).

R. Goodall and T.W. Clyne, Acta Mater. 54, 5489 (2006).

J.J. Vlassak and W.D. Nix, Philos. Mag. A 67, 1045 (1993).

L. Lu, R. Schwaiger, Z.W. Shan, M. Dao, K. Lu, and S. Suresh, Acta Mater. 53, 2169 (2005).

M.A. Meyers, A. Mishra, and D.J. Benson, Prog. Mater. Sci. 51, 427 (2006).

H. Vehoff, D. Lemaire, K. Schüler, T. Waschkies, and B. Yang, Int. J. Mater. Res. 98, 259 (2007).

X. Shen, J. Lian, Z. Jiang, and Q. Jiang, Mater. Sci. Eng. A 487, 410 (2008).

A.G. Evans and R.D. Rawlings, Phys. Status Solidi 34, 9 (1969).

A.T. Jennings, J. Li, and J.R. Greer, Acta Mater. 59, 5627 (2011).

Acknowledgements

The authors want to thank G. Bürki and A. Böll for technical assistance with the miniature tensile stage and the SEM indenter, and they thank N. Siegfried for performing the GDOES measurements. Funding by the Commission for Technology and Innovation (CTI) within the Project No. 209673 is gratefully acknowledged. G. Mohanty and G. Guillonneau would like to acknowledge funding from the EMPA post-doctoral fellowship program NANOCREEP cofunded by FP7: Marie Curie Actions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wehrs, J., Mohanty, G., Guillonneau, G. et al. Comparison of In Situ Micromechanical Strain-Rate Sensitivity Measurement Techniques. JOM 67, 1684–1693 (2015). https://doi.org/10.1007/s11837-015-1447-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-015-1447-z