Abstract

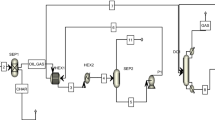

To predict and analyze the municipal solid waste (MSW) pyrolysis and gasification process in an updraft fixed bed more veritably and appropriately, numerical modeling based on Gibbs energy minimization was executed using the Aspen plus software. The RYield module was combined with the RGibbs module to describe the pyrolysis section, while the RGibbs module was used for the gasification section individually. The proposed model was used to forecast and analyze the target performance parameters including syngas composition, lower heating value (LHV) and carbon conversion rate under different conditions of the gasification temperatures, and ratios and types of gasifying agents. The results indicate that there is a good agreement between the experimental data and the simulated data obtained using this model. The predicted optimum gasification temperature is approximately 750°C, and the best ratio of water vapor as gasifying agent is around 0.4. The mixture of flue gas and water vapor has an economical and recycled prospect among four commonly used gasifying agents.

Similar content being viewed by others

References

Zhang Q L, Wu Y S, Dor L, Yang W H, Blasiak W. A thermodynamic analysis of solid waste gasification in the Plasma Gasification Melting process. Applied Energy, 2013, 112(4): 405–413

Meng A, Chen S, Zhou H, Long Y, Zhang Y, Li Q. Pyrolysis and simulation of typical components in wastes with macro-TGA. Fuel, 2015, 157(3): 1–8

Shabbar S, Janajreh I. Thermodynamic equilibrium analysis of coal gasification using Gibbs energy minimization method. Energy Conversion and Management, 2013, 65(1): 755–763

Zhao Y H,Wen H, Xu Z H. Conceptual design and simulation study of a co-gasification technology. Energy Conversion and Management, 2006, 47(11-12): 1416–1428

Zheng H X, Kaliyan N, Morey R V. Aspen plus simulation of biomass integrated gasification combined cycle systems at corn ethanol plants. Biomass and Bioenergy, 2010, 56(56): 197–210

** H. Process simulation research on high-temperature gasification of biomass with steam. Dissertation for the Master Degree. Harbin: Harbin Institute of Technology, 2013 (in Chinese)

Zheng J. Experimental study on MSWfluidized-bed gasification and the optimization of prediction model. Dissertation for the Doctoral Degree. Hangzhou: Zhejiang University, 2009 (in Chinese)

Chen C. Experimental study and process simulation on MSW pyrolysis and gasification in fixed bed. Dissertation for the Doctoral Degree. Hangzhou: Zhejiang University, 2011 (in Chinese)

Begum S, Rasul M G, Akbar D. A numerical investigation of municipal solid waste gasification using aspen plus. Procedia Engineering, 2014, 90: 710–717

Nikoo M B, Mahinpey N. Simulation of biomass gasification in fluidized bed reactor using ASPEN PLUS. Biomass and Bioenergy, 2008, 32(12): 1245–1254

Shen L H, Gao Y, **ao J. Simulation of hydrogen production from biomass gasification in interconnected fluidized beds. Biomass and Bioenergy, 2008, 32(2): 120–127

Chen C, ** Y Q, Yan J H, Chi Y. Simulation of municipal solid waste gasification in two different types of fixed bed reactors. Fuel, 2013, 103: 58–63

Luo S Y. Research on municipal solid waste shredder and effect of particle size on pyrolysis & gasification performance. Dissertation for the Doctoral Degree. Wuhan: Huazhong University of Science and Technology, 2010 (in Chinese)

He M Y, **ao B, Liu S M, Guo X J, Luo S Y, Xu Z L, Feng Y, Hu Z Q. Hydrogen-rich gas from catalytic steam gasification of municipal solid waste (MSW): influence of steam to MSW ratios and weight hourly space velocity on gas production and composition. International Journal of Hydrogen Energy, 2009, 34(5): 2174–2183

Sun L. Biomass Pyrolysis and Gasification Principles and Techniques. Bei**g: Chemical Industry Press, 2013

Acknowledgements

The work is financially supported by the National Natural Science Foundation of China (Grant No. 51406133).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Deng, N., Li, D., Zhang, Q. et al. Simulation analysis of municipal solid waste pyrolysis and gasification based on Aspen plus. Front. Energy 13, 64–70 (2019). https://doi.org/10.1007/s11708-017-0481-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11708-017-0481-7