Abstract

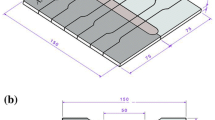

The current research aims to investigate how processing parameters influence the mechanical properties and microstructure development of dissimilar AA7075/AA6061. These alloys were friction stir welded (FSWed) at varied traverse rates (ranging from 20 to 60 mm/min) while maintaining a constant rotation rate of 708 rpm. Several characterization techniques, such as electron microscopy and optical microscopy, were utilized to quantify the microstructure evolution of these dissimilar FSWed joints. A universal testing machine and a Vickers microhardness tester were used to evaluate the mechanical characteristics. The field emission–scanning electron microscope was used to examine the fracture surfaces of the fractured tensile specimens. The experiment revealed that the grain size within the nugget zone decreased as the tool traverse rate increased from 20 to 60 mm/min. Specifically, the grain size in the nugget zone measured 5.82 µm at a speed of 20 mm/min, whereas it reduced to 3.64 µm at 60 mm/min. Furthermore, the FSWed sample processed at 60 mm/min demonstrated a superior ultimate tensile strength of 251 MPa. The hardness values exhibited a similar increasing trend as the traverse speed increased. The heat-affected zone of the AA6061 side achieved the lowest hardness at a traverse rate of 20 mm/min. A ductile fracture mode predominated for most of the dissimilar joint fracture surfaces investigated.

Similar content being viewed by others

References

W.S. Miller, L. Zhuang, J. Bottema, A.J. Wittebrood, P. De Smet, A. Haszler ,and A. Vieregge, Recent Development in Aluminium Alloys for the Automotive Industry, Mater. Sci. Eng. A, 2000, 280(1), p 37–49.

X. Peng, Q. Guo, X. Liang, Y. Deng, Y. Gu, G. Xu,and Z. Yin, Mechanical Properties, Corrosion Behavior and Microstructures of a Non-Isothermal Ageing Treated Al-Zn-Mg-Cu Alloy, Mater. Sci. Eng. A, 2016, 2017(688), p 146–154.

E. Sharghi and A. Farzadi, Simulation of Strain Rate, Material Flow, and Nugget Shape during Dissimilar Friction Stir Welding of AA6061 Aluminum Alloy and Al-Mg2Si Composite, J. Alloys Compd., 2018, 748, p 953–960. https://doi.org/10.1016/j.jallcom.2018.03.145

H.C. Fang, H. Chao,and K.H. Chen, Effect of Zr, Er and Cr Additions on Microstructures and Properties of Al-Zn-Mg-Cu Alloys, Mater. Sci. Eng. A, 2014, 610, p 10–16. https://doi.org/10.1016/j.msea.2014.05.021

R. Saravanakumar, T. Rajasekaran,and C. Pandey, Underwater Friction Stir Welded Armour Grade AA5083 Aluminum Alloys: Experimental Ballistic Performance and Corrosion Investigation, J. Mater. Eng. Perform., 2023 https://doi.org/10.1007/s11665-023-07836-2

F.F. Wang, W.Y. Li, J. Shen, S.Y. Hu,and J.F. dos Santos, Effect of Tool Rotational Speed on the Microstructure and Mechanical Properties of Bobbin Tool Friction Stir Welding of Al-Li Alloy, Mater. Des., 2015, 86, p 933–940.

K. Singh, G. Singh,and H. Singh, Review on Friction Stir Welding of Magnesium Alloys, J. Magnes. Alloy., 2018, 6(4), p 399–416. https://doi.org/10.1016/j.jma.2018.06.001

N.Z. Khan, A.N. Siddiquee, Z.A. Khan,and A.K. Mukhopadhyay, Mechanical and Microstructural Behavior of Friction Stir Welded Similar and Dissimilar Sheets of AA2219 and AA7475 Aluminium Alloys, J. Alloys Compd., 2017, 695, p 2902–2908. https://doi.org/10.1016/j.jallcom.2016.11.389

J.A.N.G. Jae-Ho, N.A.M. Dae-Geun, P.A.R.K. Yong-Ho,and P.A.R.K. Ik-Min, Effect of Solution Treatment and Artificial Aging on Microstructure and Mechanical Properties of Al-Cu Alloy, Trans. Nonferrous Met. Soc. China, 2013, 23(3), p 631–635. https://doi.org/10.1016/S1003-6326(13)62509-1

K.A. Zakaria, S. Abdullah,and M.J. Ghazali, Comparative Study of Fatigue Life Behaviour of AA6061 and AA7075 Alloys under Spectrum Loadings, Mater. Des., 2013, 49(48), p 57. https://doi.org/10.1016/j.matdes.2013.01.020

R. Beygi, H. Pouraliakbar, K. Torabi, V. Fallah, S.K. Kim, R. Shi,and L.F.M. da Silva, The Inhibitory Effect of Stir Zone Liquefaction and Eutectic-Phase Formation on the Growth of γ/β Intermetallics during Dissimilar FSW of Al/Mg Alloys, J. Manuf. Process., 2021, 70, p 152–162. https://doi.org/10.1016/j.jmapro.2021.08.049

J.R. Pickens, Aluminium Powder Metallurgy Technology for High-Strength Applications, J. Mater. Sci., 1981, 16(6), p 1437–1457.

T. Gao, Y. Zhang,and X. Liu, Influence of Trace Ti on the Microstructure, Age Hardening Behavior and Mechanical Properties of an Al-Zn-Mg-Cu-Zr Alloy, Mater. Sci. Eng. A, 2014, 598, p 293–298. https://doi.org/10.1016/j.msea.2014.01.062

T. Marlaud, B. Malki, C. Henon, A. Deschamps,and B. Baroux, Relationship between Alloy Composition, Microstructure and Exfoliation Corrosion in Al-Zn-Mg-Cu Alloys, Corros. Sci., 2011, 53(10), p 3139–3149. https://doi.org/10.1016/j.corsci.2011.05.057

T. Dursun and C. Soutis, Recent Developments in Advanced Aircraft Aluminium Alloys, Mater. Des., 2014, 56, p 862–871. https://doi.org/10.1016/j.matdes.2013.12.002

K. El-Menshawy, A.W.A. El-Sayed, M.E. El-Bedawy, H.A. Ahmed,and S.M. El-Raghy, Effect of Aging Time at Low Aging Temperatures on the Corrosion of Aluminum Alloy 6061, Corros. Sci., 2012, 54(1), p 167–173. https://doi.org/10.1016/j.corsci.2011.09.011

M.K. Hagnell, S. Kumaraswamy, T. Nyman,and M. Akermo, From Aviation to Automotivea: A Study on Material Selection and Its Implication on Cost and Weight Efficient Structural Composite and Sandwich Designs, Heliyon, 2020, 6(3), p e03716. https://doi.org/10.1016/j.heliyon.2020.e03716

M. Paidar, R.V. Vignesh, A. Moharrami, O.O. Ojo, A. Jafari,and S. Sadreddini, Development and Characterization of Dissimilar Joint between AA2024-T3 and AA6061-T6 by Modified Friction Stir Clinching Process, Vacuum, 2020, 176, p 109298. https://doi.org/10.1016/j.vacuum.2020.109298

T.F. Chung, Y.L. Yang, M. Shiojiri, C.N. Hsiao, W.C. Li, C.S. Tsao, Z. Shi, J. Lin,and J.R. Yang, An Atomic Scale Structural Investigation of Nanometre-Sized η Precipitates in the 7050 Aluminium Alloy, Acta Mater., 2019, 174, p 351–368. https://doi.org/10.1016/j.actamat.2019.05.041

J. Mohammadi, Y. Behnamian, A. Mostafaei,and A.P. Gerlich, Tool Geometry, Rotation and Travel Speeds Effects on the Properties of Dissimilar Magnesium/Aluminum Friction Stir Welded Lap Joints, Mater. Des., 2015, 75, p 95–112. https://doi.org/10.1016/j.matdes.2015.03.017

V.K. Yadav, V. Gaur,and I.V. Singh, Effect of Post-Weld Heat Treatment on Mechanical Properties and Fatigue Crack Growth Rate in Welded AA-2024, Mater. Sci. Eng. A, 2019, 2020(779), p 139116. https://doi.org/10.1016/j.msea.2020.139116

S. Sinhmar and D.K. Dwivedi, A Study on Corrosion Behavior of Friction Stir Welded and Tungsten Inert Gas Welded AA2014 Aluminium Alloy, Corros. Sci., 2018, 133(January), p 25–35. https://doi.org/10.1016/j.corsci.2018.01.012

W.M.T.E. D., J.C. Nicholas, M.G. Needham, Saffron Walden, H.P.T.-S. Murch, C.J. Dawes, Cambridge, and Cambs, “FRICTION WELDING,” (United Kingdom), 1995

R. Saravanakumar, T. Rajasekaran, C. Pandey,and M. Menaka, Influence of Tool Probe Profiles on the Microstructure and Mechanical Properties of Underwater Friction Stir Welded AA5083 Material, J. Mater. Eng. Perform., 2022, 31(10), p 8433–8450. https://doi.org/10.1007/s11665-022-06822-4

B. Li and Y. Shen, A Feasibility Research on Friction Stir Welding of a New-Typed Lap–Butt Joint of Dissimilar Al Alloys, Mater. Des., 2012, 34, p 725–731.

R. Palanivel, P.K. Mathews, N. Murugan,and I. Dinaharan, Effect of Tool Rotational Speed and Pin Profile on Microstructure and Tensile Strength of Dissimilar Friction Stir Welded AA5083-H111 and AA6351-T6 Aluminum Alloys, Mater. Des., 2012, 40, p 7–16. https://doi.org/10.1016/j.matdes.2012.03.027

O. Hatamleh and A. DeWald, An Investigation of the Peening Effects on the Residual Stresses in Friction Stir Welded 2195 and 7075 Aluminum Alloy Joints, J. Mater. Process. Technol., 2009, 209(10), p 4822–4829.

E.G. Cole, A. Fehrenbacher, N.A. Duffie, M.R. Zinn, F.E. Pfefferkorn,and N.J. Ferrier, Weld Temperature Effects during Friction Stir Welding of Dissimilar Aluminum Alloys 6061–t6 and 7075–t6, Int. J. Adv. Manuf. Technol., 2014, 71, p 643–652.

H.K. Pabandi, H.R. Jashnani,and M. Paidar, Effect of Precipitation Hardening Heat Treatment on Mechanical and Microstructure Features of Dissimilar Friction Stir Welded AA2024-T6 and AA6061-T6 Alloys, J. Manuf. Process., 2018, 31, p 214–220. https://doi.org/10.1016/j.jmapro.2017.11.019

R. Saravanakumar, T. Rajasekaran,and C. Pandey, Optimisation of Underwater Friction Stir Welding Parameters of Aluminum Alloy AA5083 using RSM and GRA, Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng., 2022 https://doi.org/10.1177/09544089221134446

L. Giraud, H. Robe, C. Claudin, C. Desrayaud, P. Bocher,and E. Feulvarch, Investigation into the Dissimilar Friction Stir Welding of AA7020-T651 and AA6060-T6, J. Mater. Process. Technol., 2016, 235, p 220–230.

P.B. Srinivasan, W. Dietzel, R. Zettler, J.F. Dos Santos,and V. Sivan, Effects of Inhibitors on Corrosion Behaviour of Dissimilar Aluminium Alloy Friction Stir Weldment, Corros. Eng. Sci. Technol., 2007, 42(2), p 161–167.

M. Ilangovan, S.R. Boopathy,and V. Balasubramanian, Microstructure and Tensile Properties of Friction Stir Welded Dissimilar AA6061-AA5086 Aluminium Alloy Joints, Trans. Nonferrous Met. Soc. China, 2015, 25(4), p 1080–1090. https://doi.org/10.1016/S1003-6326(15)63701-3

C.A.W. Olea, L. Roldo, J.F. dos Santos,and T.R. Strohaecker, A Sub-Structural Analysis of Friction Stir Welded Joints in an AA6056 Al-Alloy in T4 and T6 Temper Conditions, Mater. Sci. Eng. A, 2007, 454–455, p 52–62.

Y.S. Sato, H. Kokawa, M. Enomoto,and S. Jogan, Microstructural Evolution of 6063 Aluminum during Friction-Stir Welding, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 1999, 30(9), p 2429–2437.

P.L. Niu, W.Y. Li, A. Vairis,and D.L. Chen, Cyclic Deformation Behavior of Friction-Stir-Welded Dissimilar AA5083-to-AA2024 Joints: Effect of Microstructure and Loading History, Mater. Sci. Eng. A, 2018, 2019(744), p 145–153.

M. Cabibbo, H.J. McQueen, E. Evangelista, S. Spigarelli, M. Di Paola,and A. Falchero, Microstructure and Mechanical Property Studies of AA6056 Friction Stir Welded Plate, Mater. Sci. Eng. A, 2007, 460–461, p 86–94.

A.P. Reynolds, W. Tang, Z. Khandkar, J.A. Khan,and K. Lindner, Relationships between Weld Parameters, Hardness Distribution and Temperature History in Alloy 7050 Friction Stir Welds, Sci. Technol. Weld. Join., 2005, 10(2), p 190–199.

Y. Chen, H. Wang, X. Wang, H. Ding, J. Zhao, F. Zhang,and Z. Ren, Influence of Tool Pin Eccentricity on Microstructural Evolution and Mechanical Properties of Friction Stir Processed Al-5052 Alloy, Mater. Sci. Eng. A, 2018, 2019(739), p 272–276.

M. Guerra, C. Schmidt, J.C. McClure, L.E. Murr,and A.C. Nunes, Flow Patterns during Friction Stir Welding, Mater Charact, 2002, 49(2), p 95–101.

K.N. Krishnan, On the Formation of Onion Rings in Friction, Stir Welds, Mater. Sci. Eng. A, 2002, 327(2), p 246–251.

C. Zhang, G. Huang, Y. Cao, Y. Zhu, W. Li, X. Wang,and Q. Liu, Microstructure and Mechanical Properties of Dissimilar Friction Stir Welded AA2024-7075 Joints Influence of Joining Material Direction, Mater. Sci. Eng. A, 2019, 766(March), p 138368. https://doi.org/10.1016/j.msea.2019.138368

T. Azimzadegan and S. Serajzadeh, An Investigation into Microstructures and Mechanical Properties of AA7075-T6 during Friction Stir Welding at Relatively High Rotational Speeds, J. Mater. Eng. Perform., 2010, 19(9), p 1256–1263.

J.Q. Su, T.W. Nelson,and C.J. Sterling, Microstructure Evolution during FSW/FSP of High Strength Aluminum Alloys, Mater. Sci. Eng. A, 2005, 405(1–2), p 277–286.

S. Raja, M.R. Muhamad, M.F. Jamaludin,and F. Yusof, A Review on Nanomaterials Reinforcement in Friction Stir Welding, J. Mater. Res. Technol., 2020, 9(6), p 16459–16487. https://doi.org/10.1016/j.jmrt.2020.11.072

P. Carlone and G.S. Palazzo, Influence of Process Parameters on Microstructure and Mechanical Properties in AA2024-T3 Friction Stir Welding, Metallogr. Microstruct. Anal., 2013, 2(4), p 213–222.

A. Heidarzadeh, S. Mironov, R. Kaibyshev, G. Çam, A. Simar, A. Gerlich, F. Khodabakhshi, A. Mostafaei, D.P. Field, J.D. Robson, A. Deschamps,and P.J. Withers, Friction Stir Welding/Processing of Metals and Alloys: A Comprehensive Review on Microstructural Evolution, Prog. Mater. Sci., 2020, 2020(117), p 100752. https://doi.org/10.1016/j.pmatsci.2020.100752

Y.G. Kim, H. Fujii, T. Tsumura, T. Komazaki,and K. Nakata, Three Defect Types in Friction Stir Welding of Aluminum Die Casting Alloy, Mater. Sci. Eng. A, 2006, 415(1–2), p 250–254.

M. Paidar, K. Tahani, R. Vaira Vignesh, O.O. Ojo, H.R. Ezatpour,and A. Moharrami, Modified Friction Stir Clinching of 2024–T3 to 6061–T6 Aluminium Alloy Effect of Dwell Time and Precipitation-Hardening Heat Treatment, Mater. Sci. Eng. A, 2020, 791(June), p 139734. https://doi.org/10.1016/j.msea.2020.139734

T.R. McNelley, S. Swaminathan,and J.Q. Su, Recrystallization Mechanisms during Friction Stir Welding/Processing of Aluminum Alloys, Scr. Mater., 2008, 58(5), p 349–354.

H. Suthar, A. Bhattacharya,and S.K. Paul, Local Deformation Response and Failure Behavior of AA6061-AA6061 and AA6061-AA7075 Friction Stir Welds, CIRP J. Manuf. Sci. Technol., 2020, 30, p 12–24. https://doi.org/10.1016/j.cirpj.2020.03.006

K.V. Jata and S.L. Semiatin, Continuous Dynamic Recrystallization during Friction Stir Welding of High Strength Aluminum Alloys, Scr. Mater., 2000, 43(8), p 743–749.

M. Mahdi, H. Jamshidi, R. Jamaati,and S. Amirkhanlou, Materials Characterization Effect of SiC Nanoparticles on the Microstructure and Texture of Friction Stir, Mater Charact, 2019, 152(March), p 169–179. https://doi.org/10.1016/j.matchar.2019.04.020

H. Jamshidi Aval, S. Serajzadeh, N.A. Sakharova, A.H. Kokabi,and A. Loureiro, A Study on Microstructures and Residual Stress Distributions in Dissimilar Friction-Stir Welding of AA5086-AA6061, J. Mater. Sci., 2012, 47(14), p 5428–5437.

H. Jamshidi Aval, Influences of Pin Profile on the Mechanical and Microstructural Behaviors in Dissimilar Friction Stir Welded AA6082-AA7075 Butt Joint, Mater. Des., 2015, 67, p 413–421. https://doi.org/10.1016/j.matdes.2014.11.055

A.A.M. da Silva, E. Arruti, G. Janeiro, E. Aldanondo, P. Alvarez,and A. Echeverria, Material Flow and Mechanical Behaviour of Dissimilar AA2024-T3 and AA7075-T6 Aluminium Alloys Friction Stir Welds, Mater. Des., 2011, 32(4), p 2021–2027. https://doi.org/10.1016/j.matdes.2010.11.059

S.T. Amancio-Filho, S. Sheikhi, J.F. dos Santos,and C. Bolfarini, Preliminary Study on the Microstructure and Mechanical Properties of Dissimilar Friction Stir Welds in Aircraft Aluminium Alloys 2024–T351 and 6056–T4, J. Mater. Process. Technol., 2008, 206(1–3), p 132–142.

M. Koilraj, V. Sundareswaran, S. Vijayan,and S.R. Koteswara Rao, Friction Stir Welding of Dissimilar Aluminum Alloys AA2219 to AA5083 Optimization of Process Parameters Using Taguchi Technique, Mater. Des., 2012, 42, p 1–7. https://doi.org/10.1016/j.matdes.2012.02.016

Acknowledgements

The authors are highly grateful for the Institute Assistantship IIT Roorkee offered to the first author to carry out the present work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rana, R., Karmakar, A. & Karunakar, D.B. Effect of Tool Travel Rate on Microstructure Evolution and Mechanical Properties of Dissimilar Friction Stir Welded Joints of AA7075 and AA6061 Aluminium Alloys. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08759-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08759-8