Abstract

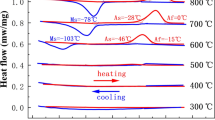

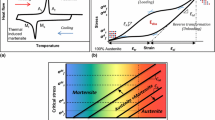

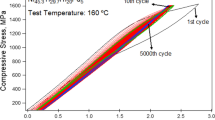

The prestressing applications of shape memory alloys (SMAs) employs the recovery stress of a constrained SMA element that originates from its attempt to revert a pre-deformation to original shape upon heating. As the most readily available SMAs, NiTi alloys have shown poor performance of recovery stress compared to NiTiNb and FeMnSiCrNi due to their relatively small transformation hysteresis. This work investigated the effects of heat treatment and prestraining on the martensitic phase transformation characteristics and mechanical properties. It is found that suitably selected heat treatment and prestraining treatment can effectively tune the transformation hysteresis to greater than 100 °C while retaining reasonably high strength, which greatly elevate the recovery stress of NiTi–SMAs. A large recovery stresses of approximately 300 MPa with a wide temperature window of 180 °C of stable performance can be achieved via a simple one-step heat treatment and prestraining treatment using commercial superelastic NiTi wire products.

Similar content being viewed by others

Data availability

The raw data required to reproduce these findings are available from the corresponding author by request.

References

C.N. Saikrishna, K.V. Ramaiah, and S.K. Bhaumik, Effects of Thermo-Mechanical Cycling on the Strain Response of Ni–Ti–Cu Shape Memory Alloy Wire Actuator, Mater. Sci. Eng. A, 2006, 428(1), p 217–224.

A. Ishida, M. Sato, K. Ogawa, and K. Yamada, Shape Memory Behavior of Ti–Ni–Cu Thin Films, Mater. Sci. Eng. A, 2006, 438–440, p 683–686.

W. **nmei, Xu. Baoxing, and Y. Zhufeng, Phase Transformation Behavior of Pseudoelastic NiTi Shape Memory Alloys under Large Strain, J. Alloy. Compd., 2008, 463(1–2), p 417–422.

A.M. Condó, F.C. Lovey, J. Olbricht, C. Somsen, and A. Yawny, Microstructural Aspects Related to Pseudoelastic Cycling in Ultra Fine Grained Ni–Ti, Mater. Sci. Eng. A, 2008, 481–482, p 138–141.

N.A. Mansour, A.M.R.F. El-Bab, S.F.M. Assal, and O. Tabata, Design, Characterization and Control of SMA Springs-Based Multi-Modal Tactile Display Device for Biomedical Applications, Mechatronics, 2015, 31, p 255–263.

S. Li, Y.-W. Kim, M.-S. Choi, J.G. Kim, and T.-H. Nam, Superelasticity, Microstructure and Texture Characteristics of the Rapidly Solidified Ti–Zr–Nb–Sn Shape Memory Alloy Fibers for Biomedical Applications, Mater. Sci. Eng. A, 2022, 831, p 142001.

F. Gok, S.K. Buyuk, S. Ozkan, and Y.A. Benkli, Comparison of Arch Width and Depth Changes and Pain/Discomfort with Conventional and Copper Ni-Ti Archwires for Mandibular Arch Alignment, J. World Fed. Orthod., 2018, 7(1), p 24–28.

H. Hashemzadeh, M. Soleimani, M. Golbar, A.D. Soltani, and S.P. Mirmalek, Canine and Molar Movement, Rotation and Tip** by NiTi Coils versus Elastomeric Chains in First Maxillary Premolar Extraction Orthodontic Adolescents: A Randomized Split-Mouth Study, Int. Orthod., 2022, 20(1), p 100601.

A. Riccio, A. Sellitto, S. Ameduri, A. Concilio, and M. Arena, Chapter 24–Shape memory alloys (SMA) for automotive applications and challenges, Shape Memory Alloy Engineering (Second Edition). A. Concilio, V. Antonucci, F. Auricchio, L. Lecce, E. Sacco Ed., Butterworth-Heinemann, Boston, 2021, p 785–808

D. Stoeckel, Shape Memory Actuators for Automotive Applications, Mater. Des., 1990, 11(6), p 302–307.

A. Villanueva, C. Smith, and S. Priya, A Biomimetic Robotic Jellyfish (Robojelly) Actuated by Shape Memory Alloy Composite Actuators, Bioinspir. Biomim., 2011, 6(3), p 036004.

M. Sreekumar, T. Nagarajan, M. Singaperumal, M. Zoppi, and R. Molfino, Critical Review of Current Trends in Shape Memory Alloy Actuators for Intelligent Robots, Ind. Robot Int. J. Robot. Res. Appl., 2007, 34(4), p 285–294.

D.J. Hartl and D.C. Lagoudas, Aerospace Applications of Shape Memory Alloys, Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng., 2007, 221(G4), p 535–552.

C. Fang, W. Wang, C.X. Qiu, S.L. Hu, G.A. MacRae, and M.R. Eatherton, Seismic Resilient Steel Structures: A Review of Research, Practice, Challenges and Opportunities, J. Constr. Steel Res., 2022, 191, p 107172.

J. Almeida, M. Steinmetz, F. Rigot, and S.D. Cock, Shape-Memory NiTi alloy Rebars in Flexural-Controlled Large-Scale Reinforced Concrete Walls: Experimental Investigation on Self-Centring and Damage Limitation, Eng. Struct., 2020, 220, p 110865.

L. Cortes-Puentes, M. Zaidi, D. Palermo, and E. Dragomirescu, Cyclic Loading Testing of Repaired SMA and Steel Reinforced Concrete Shear Walls, Eng. Struct., 2018, 168, p 128–141.

A. Billah and M.S. Alam, Seismic Performance of Concrete Columns Reinforced with Hybrid Shape Memory Alloy (SMA) and Fiber Reinforced Polymer (FRP) Bars, Constr. Build. Mater., 2012, 28(1), p 730–742.

M. Miralami, M.R. Esfahani, and M. Tavakkolizadeh, Strengthening of Circular RC Column-Foundation Connections with GFRP/SMA Bars and CFRP Wraps, Compos. B Eng., 2019, 172, p 161–172.

M.M. Sherif, E.M. Khakimova, J. Tanks, and O.E. Ozbulut, Cyclic Flexural Behavior of Hybrid SMA/Steel Fiber Reinforced Concrete Analyzed by Optical and Acoustic Techniques, Compos. Struct., 2018, 201, p 248–260.

H. Li, Z.-Q. Liu, and J.-P. Ou, Experimental Study of a Simple Reinforced Concrete Beam Temporarily Strengthened by SMA Wires Followed by Permanent Strengthening with CFRP Plates, Eng. Struct., 2008, 30(3), p 716–723.

G. McGavin, G. Guerin, Real-Time Seismic Dam** and Frequency Control of Steel Structures using Nitinol Wire. In: Smart Structures and Materials 2002 Conference, San Diego, Ca, 2002, pp. 176-185

G. Song, N. Ma, and H.N. Li, Applications of Shape Memory Alloys in Civil Structures, Eng. Struct., 2006, 28(9), p 1266–1274.

K. Zeynali, H.S. Monir, N.M. Mirzai, and J.W. Hu, Experimental and Numerical Investigation of Lead-Rubber Dampers in Chevron Concentrically Braced Frames, Arch Civ Mech Eng, 2018, 18(1), p 162–178.

S. Sun, R. Rajapakse, Dynamic Response of a Frame with SMA Bracing. In: Smart Structures and Materials 2003 Conference, San Diego, Ca, 2003, pp. 262-270

Y. Zhang and S. Zhu, A Shape Memory Alloy-Based Reusable Hysteretic Damper for Seismic Hazard Mitigation, Smart Mater. Struct., 2007, 16(5), p 1603.

E. Choi, S.C. Cho, J.W. Hu, T. Park, and Y.S. Chung, Recovery and Residual Stress of SMA Wires and Applications for Concrete Structures, Smart Mater. Struct., 2010, 19(9), p 094013.

R. El-Hacha and K. Abdelrahman, Behaviour of circular SMA-Confined Reinforced Concrete Columns Subjected to Eccentric Loading, Eng. Struct., 2020, 215, p 110443.

R. Suhail, G. Amato, and D.P. McCrum, Active and Passive Confinement of Shape Modified Low Strength Concrete Columns using SMA and FRP Systems, Compos. Struct., 2020, 251, p 112649.

J.-H. Lee, E. Choi, and J.-S. Jeon, Experimental Investigation on the Performance of Flexural Displacement Recovery using Crimped Shape Memory Alloy Fibers, Constr. Build. Mater., 2021, 306, p 124908.

E. Choi, J.-S. Jeon, and J.-H. Lee, Active Action of Prestressing on Direct Tensile Behavior of Mortar Reinforced with NiTi SMA Crimped Fibers, Compos. Struct., 2022, 281, p 115119.

E. Choi, A. Ostadrahimi, Y. Lee, J.-S. Jeon, and I. Kim, Enabling Shape Memory Effect Wires for Acting Like Superelastic Wires in Terms of Showing Recentering Capacity in Mortar Beams, Constr. Build. Mater., 2022, 319, p 126047.

A.I. Abdy, H.M. Javad, and A.M. Riadh, Fatigue Life Improvement of Steel Structures Using Self-Prestressing CFRP/SMA Hybrid Composite Patches, Eng. Struct., 2018, 174, p 358–372.

M. El-Tahan, M. Dawood, and G. Song, Development of a Self-Stressing NiTiNb Shape Memory Alloy (SMA)/Fiber Reinforced Polymer (FRP) Patch, Smart Mater. Struct., 2015, 24(6), p 065035.

L. Li, T. Chen, X. Gu, and E. Ghafoori, Heat Activated SMA-CFRP Composites for Fatigue Strengthening of Cracked Steel Plates, J. Compos. Constr., 2020, 24(6), p 04020060.

F. Taheri-Behrooz, F. Taheri, and R. Hosseinzadeh, Characterization of a Shape Memory Alloy Hybrid Composite Plate Subject to Static Loading, Mater. Des., 2011, 32(5), p 2923–2933.

K. Yuse and Y. Kikushima, Development and Experimental Considerations on SMA/CFRP Hybrid Actuator for Vibration Control, Sens. Actuators A, 2005, 122(1), p 99–107.

B. Zheng and M. Dawood, Fatigue Crack Growth Analysis of Steel Elements Reinforced with Shape Memory Alloy (SMA)/Fiber Reinforced Polymer (FRP) Composite Patches, Compos. Struct., 2017, 164, p 158–169.

M. Dawood, M.W. El-Tahan, and B. Zheng, Bond Behavior of Superelastic Shape Memory Alloys to Carbon Fiber Reinforced Polymer Composites, Compos. B Eng., 2015, 77, p 238–247.

M. El-Tahan and M. Dawood, Bond Behavior of NiTiNb SMA Wires embedded in CFRP Composites, Polym. Compos., 2018, 39(10), p 3780–3791.

B. Zheng and M. Dawood, Fatigue Strengthening of Metallic Structures with a Thermally Activated Shape Memory Alloy Fiber-Reinforced Polymer Patch, J. Compos. Constr., 2017, 21(4), p 04016113.

Z. Gang and P. Lloyd, Design, Manufacture and Evaluation of Bending Behaviour of Composite beams Embedded with SMA Wires, Compos. Sci. Technol., 2009, 69(13), p 2034–2041.

B.T. Zheng, M. El-Tahan, and M. Dawood, Shape Memory Alloy-Carbon Fiber Reinforced Polymer System for Strengthening Fatigue-Sensitive Metallic Structures, Eng. Struct., 2018, 171, p 190–201.

E. Fritsch, M. Izadi, and E. Ghafoori, Development of Nail-Anchor Strengthening System with Iron-Based Shape Memory Alloy (Fe-SMA) Strips, Constr. Build. Mater., 2019, 229, p 117042.

A. Hosseini, J. Michels, M. Izadi. and E. Ghafoori, A Comparative Study Between Fe-SMA and CFRP Reinforcements for Prestressed Strengthening of Metallic Structures, Constr. Build. Mater., 2019, 226, p 976–992.

M. Izadi, A. Hosseini, J. Michels, M. Motavalli. and E. Ghafoori, Thermally Activated Iron-Based Shape Memory Alloy for Strengthening Metallic Girders, Thin Wall. Struct., 2019, 141, p 389–401.

M.R. Izadi, E. Ghafoori, M. Shahverdi, M. Motavalli. and S. Maalek, Development of an Iron-Based Shape Memory Alloy (Fe-SMA) Strengthening System for Steel Plates, Eng. Struct., 2018, 174, p 433–446.

M.R. Izadi, E. Ghafoori, M. Motavalli. and S. Maalek, Iron-Based Shape Memory Alloy for the Fatigue Strengthening of Cracked Steel Plates: Effects of re-activations and loading frequencies, Eng. Struct., 2018, 176, p 953–967.

B. Schranz, C. Czaderski, T. Vogel. and M. Shahverdi, Bond Investigations of Prestressed, Near-Surface-Mounted, Ribbed Memory-Steel Bars with Full Bond Length, Mater. Des., 2020, 196, p 109145.

R. Suhail, G. Amato. and D. McCrum, Heat-Activated Prestressing of NiTiNb Shape Memory Alloy wires, Eng. Struct., 2020, 206, p 110128.

K. Hong, S. Lee, S. Han. and Y. Yeon, Evaluation of Fe-Based Shape Memory Alloy (Fe-SMA) as Strengthening Material for Reinforced Concrete Structures, Appl. Sci., 2018, 8(5), p 730.

Z.G. Wang, X.T. Zu, X.D. Feng, S. Zhu, J.M. Zhou. and L.M. Wang, Annealing-Induced Evolution of Transformation Characteristics in TiNi Shape Memory Alloys, Phys. B Phys. Condens. Matter, 2004, 353(1–2), p 9–14.

J. Khalil-Allafi, A. Dlouhy. and G. Eggeler, Ni4Ti3-Precipitation During Aging of NiTi Shape Memory Alloys and its Influence on Martensitic Phase Transformations, Acta Mater., 2002, 50(17), p 4255–4274.

J.K. Allafi, X. Ren. and G. Eggeler, The Mechanism of Multistage Martensitic Transformations in Aged Ni-rich NiTi Shape Memory Alloys, Acta Mater., 2002, 50(4), p 793–803.

A. Radi, J. Khalil-Allafi, M.R. Etminanfar, S. Pourbabak, D. Schryvers. and B. Amin-Ahmadi, Influence of Stress Aging Process on Variants of Nano-Ni4Ti3 Precipitates and Martensitic Transformation Temperatures in NiTi Shape Memory Alloy, Mater. Des., 2018, 142, p 93–100.

V. Abbasi-Chianeh and J. Khalil-Allafi, Influence of Applying External stress During Aging on Martensitic Transformation and the Superelastic Behavior of a Ni-rich NiTi Alloy, Mater. Sci. Eng. A, 2011, 528(15), p 5060–5065.

K. Kazemi-Choobi, J. Khalil-Allafi. and V. Abbasi-Chianeh, Investigation of the Recovery and recrystallization Processes of Ni50.9Ti49.1 Shape Memory Wires Using in Situ Electrical Resistance Measurement, Mater. Sci. Eng. A, 2012, 551, p 122–127.

G.B. Cho, Y.H. Kim, S.G. Hur, C.A. Yu. and T.H. Nam, Transformation Behavior and Mechanical Properties of a Nanostructured Ti50.0Ni(at.%) Alloy, Metals Mater. Int., 2006, 12(2), p 181–187.

Y. Liu, Mechanical Stabilisation of Martensite due to Cold Deformation, Mater. Sci. Eng. A, 1999, 273–275, p 668–672.

M. Piao, K. Otsuka, S. Miyazaki. and H. Horikawa, Mechanism of the As Temperature Increase by Pre-deformation in Thermoelastic Alloys, Mater. Trans. JIM, 1993, 34(10), p 919–929.

E. Choi, T.H. Nam, S.J. Yoon, S.K. Cho. and J. Park, Confining Jackets for Concrete Cylinders Using NiTiNb and NiTi Shape Memory Alloy Wires, Phys. Scr., 2010, 2010(T139), p 014058.

E. Choi, H.V. Ho. and J.S. Jeon, Active Reinforcing Fiber of Cementitious Materials Using Crimped NiTi SMA Fiber for Crack-Bridging and Pullout Resistance, Materials, 2020, 13(17), p 3845.

Y.F. Li, X.J. Mi, X.Q. Yin. and H.F. **e, Constrained Recovery Properties of NiTi Shape Memory Alloy Wire During Thermal Cycling, J. Alloy. Compd., 2014, 588, p 525–529.

E. Choi, A. Ostadrahimi. and J.H. Lee, Pullout Resistance of Crimped Reinforcing Fibers Using Cold-Drawn NiTi SMA Wires, Constr. Build. Mater., 2020, 265, p 120858.

Y.G. Lim and W.J. Kim, Characteristics and Interrelation of Recovery Stress and Recovery Strain of an Ultrafine-Grained Ni-50.2Ti Alloy Processed by High-Ratio Differential Speed Rolling, Smart Mater. Struct., 2017, 26(3), p 035005.

Y. Xu, K. Otsuka, H. Yoshida, H. Nagai, R. Oishi, H. Horikawa. and T. Kishi, A New Method for Fabricating SMA/CFRP Smart Hybrid Composites, Intermetallics, 2002, 10(4), p 361–369.

J. Font, E. Cesari, J. Muntasell. and J. Pons, Thermomechanical Cycling in Cu–Al–Ni-Based Melt-Spun Shape-Memory Ribbons, Mater. Sci. Eng. A, 2003, 354(1), p 207–211.

Acknowledgements

Zhigang Wu would like to acknowledge the financial support from the Hundred Talents Program of Guangzhou University (Grant No.: RQ2021016). The authors wish to acknowledge the financial support from the Natural Science Foundation of Guangdong Province (Grant No.: 2018A030313742 and 2020A1515011064) and the Guangzhou University Postgraduate Innovation Ability Training Funding Program (Grant No.: 2019GDJC-M43 and 2020GDJC-M43) and the National Natural Science Foundation of China (Project No. 52178278).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yang, C., Liu, T., Zhong, M. et al. High Recovery Stress Performance of NiTi Shape Memory Alloy with a Wide Temperature Window. J. of Materi Eng and Perform 32, 10956–10968 (2023). https://doi.org/10.1007/s11665-023-07886-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-07886-6