Abstract

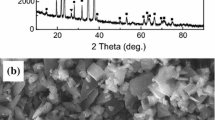

B4C-TiB2 composite was synthesized by in situ reaction of TiO2, C, and B4C during vacuum hot pressing. The composition of the composite was varied from 0 to 20 vol.% TiB2. The reaction step was controlled to produce homogenous distribution of TiB2 in B4C matrix with ~ 100% density. The hardness, bending strength, and fracture toughness of B4C monolith and B4C-TiB2 composite were evaluated. B4C-TiB2 composite with 20 vol.% TiB2 content showed 39.4 GPa hardness, 800 MPa bending strength, and 9.8 MPa.m1/2 fracture toughness. The increase in hardness, bending strength, and fracture toughness in B4C-TiB2 composite sample was 29, 56, and 292%, respectively, as compared to B4C monolith. Improvement in hardness and bending strength is attributed to the smaller grain size, i.e., 1.3 µm. The increase in fracture toughness is due to the presence of free carbon at the B4C-TiB2 interface, which creates micro-cracks at the interfacial boundary.

Similar content being viewed by others

Data Availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

G.H. Rafi-ud-din et al., Ethylene Glycol Assisted Low-Temperature Synthesis of Boron Carbide Powder from Borate Citrate Precursors, J. Asian Ceram. Soc, 2014, 2(3), p 268–274.

L. Liu et al., Sintering Dense Boron Carbide Without Grain Growth under High Pressure, J. Am. Ceram. Soc., 2018, 101(3), p 1289–1297.

X. Zhang et al., Effects of Pressure on Densification Behaviour, Microstructures and Mechanical Properties of Boron Carbide Ceramics Fabricated by Hot Pressing, Ceram. Int., 2017, 43(8), p 6345–6352.

M. Zhang et al., Analysis of Abnormal Grain Growth Behavior during Hot-Press Sintering of Boron Carbide, Ceram. Int., 2020, 46(10), p 16345–16353.

W. Zhang, A Review of Tribological Properties for Boron Carbide Ceramics, Prog. Mater Sci., 2021, 116, p 100718.

J. Deng et al., Microstructure and Mechanical Properties of hot-Pressed B4C/(W, Ti) C Ceramic Composites, Ceram. Int., 2002, 28(4), p 425–430.

F. Thevenot, Sintering of Boron Carbide and Boron Carbide-silicon Carbide Two-phase Materials and Their Properties, J. Nucl. Mater., 1988, 152(2–3), p 154–162.

S.S. Rehman et al., Microstructure and Mechanical Properties of B4C Densified by Spark Plasma Sintering with Si as a Sintering Aid, Ceram. Int., 2015, 41(1), p 1903–1906.

C. Hwang et al., Small Amount TiB2 Addition into B4C through Sputter Deposition and Hot Pressing, J. Am. Ceram. Soc., 2019, 102(8), p 4421–4426.

S. Yamada et al., High Strength B4C–TiB2 Composites Fabricated by Reaction Hot-Pressing, J. Eur. Ceram. Soc., 2003, 23(7), p 1123–1130.

X. Ding et al., Effects of TiC Particle Size on Microstructures and Mechanical Properties of B4C–TiB2 Composites Prepared by Reactive Hot-Press Sintering of TiC–B Mixtures, Ceram. Int., 2020, 46(8), p 10425–10430.

D. Jianxin, and S. Junlong, Microstructure and Mechanical Properties of hot-pressed B4C/TiC/Mo Ceramic Composites, Ceram. Int., 2009, 35(2), p 771–778.

X. Zhang et al., Microstructure and Mechanical Properties of B4C–TiB2–SiC Composites Toughened by Composite Structural Toughening Phases, J. Am. Ceram. Soc., 2017, 100(7), p 3099–3107.

A. Suri et al., Synthesis and Consolidation of Boron Carbide: A Review, Int. Mater. Rev., 2010, 55(1), p 4–40.

R. Telle, and G. Petzow, Strengthening and Toughening of Boride and Carbide Hard Material Composites, Mater. Sci. Eng., A, 1988, 105, p 97–104.

S. Huang et al., Microstructure and Mechanical Properties of Pulsed Electric Current SINTERED B4C–TiB2 Composites, Mater. Sci. Eng., A, 2011, 528(3), p 1302–1309.

L.S. Sigl, and H.J. Kleebe, Microcracking in B4C-TiB2 Composites, J. Am. Ceram. Soc., 1995, 78(9), p 2374–2380.

X. Zhang et al., High-Performance B4C–TiB2–SiC Composites with Tuneable Properties Fabricated by Reactive Hot Pressing, J. Eur. Ceram. Soc., 2019, 39(10), p 2995–3002.

Y. Liu et al., Microstructure and Mechanical Properties of B4C–TiB2–SiC Composites Fabricated by Spark Plasma Sintering, Ceram. Int., 2020, 46(3), p 3793–3800.

V.V. Skorokhod, Processing, Microstructure, and Mechanical Properties of B4C–TiB2 Particulate Sintered Composites. Part II. Fracture and Mechanical Properties, Powder Metall. Metal Ceram., 2000, 39(9), p 504–513.

J. Zhao et al., Influences of B4C Content and Particle Size on the Mechanical Properties of Hot Pressed TiB2–B4C Composites, J. Asian Ceram. Soc., 2021, 9(3), p 1239–1247.

M. Hu et al., Synthesis and Performance of TiB2–B4C Composites by High Pressure of TiC–B Mixture, Int. J. Appl. Ceram. Technol., 2020, 17(4), p 1629–1635.

X.Y. Yue et al. Microstructures and Mechanical Properties of B4C-TiB2 Composite Prepared by Hot Pressure Sintering. in Key Engineering Materials. 2010. Trans Tech Publ.

Z. Liu et al., Effects of B4C Particle Size on the Microstructures and Mechanical Properties of Hot-Pressed B4C–TiB2 Composites, Ceram. Int., 2018, 44(17), p 21415–21420.

P. Švec, Z. Gábrišová, and A. Brusilová, Reactive Sintering of B4C-TiB2 Composites from B4 and TiO2 Precursors, Process. Appl. Ceram., 2020, 14(4), p 329–335.

W. Rubink et al., Spark Plasma Sintering of B4C and B4C-TiB2 Composites: Deformation and Failure Mechanisms under Quasistatic and Dynamic Loading, J. Eur. Ceram. Soc., 2021, 41(6), p 3321–3332.

L. Levin, N. Frage, and M. Dariel, The Effect of Ti and TiO2 Additions on the Pressureless Sintering of B4C, Metall. Mater. Trans. A., 1999, 30(12), p 3201–3210.

Y.-J. Wang et al., Effect of TiB2 Content on Microstructure and Mechanical Properties of In-Situ Fabricated TiB2/B4C Composites, Trans. Nonferrous Metals Soc. China, 2011, 21, p s369–s373.

H. Baharvandi, and A. Hadian, Pressureless Sintering of TiB2-B4C Ceramic Matrix Composite, J. Mater. Eng. Perform., 2008, 17(6), p 838–841.

V. Skorokhod, M.D. Vlajic, and V.D. Krstic, Mechanical Properties of Pressureless Sintered Boron Carbide Containing TiB2 Phase, J. Mater. Sci. Lett., 1996, 15(15), p 1337–1339.

B. Uygun et al. Production and Characterization of Boron Carbide–Titanium Diboride Ceramics by Spark Plasma Sintering Method. in Advances in Science and Technology. 2010. Trans Tech Publ.

S.G. Huang et al., In situ Synthesis and Densification of Submicrometer-Grained B4C–TiB2 Composites by Pulsed Electric Current Sintering, J. Eur. Ceram. Soc., 2011, 31(4), p 637–644.

J. Pelleg, The Strength and Strengthening of Ceramics, Mechanical Properties of Ceramics. Springer, 2014, p 351–415

Q. He et al., Microstructures and Mechanical Properties of B4C-TiB2-SiC Composites Fabricated by Ball Milling and Hot Pressing, J. Eur. Ceram. Soc., 2018, 38(7), p 2832–2840.

R.M. White, and E.C. Dickey, Mechanical properties and deformation Mechanisms of B4C–TiB2 Eutectic Composites, J. Eur. Ceram. Soc., 2014, 34(9), p 2043–2050.

P. He et al., Microstructure and Mechanical Properties of B4C–TiB2 Composites Prepared by Reaction Hot Pressing using Ti3SiC2 as Additive, Ceram. Int., 2016, 42(1), p 650–656.

Acknowledgments

The authors would like to thank the Head of Department, Process Engineering Group and Powder Synthesis and Processing Group PINSTECH Islamabad, for permitting us to utilize their resources for this work. The authors also feel indebted to the Materials Division, National Institute of Laser and Optics, Islamabad, for their generous support in microstructural characterization.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Asghar, Z., Aziz, T., Khan, A.R. et al. High-Hardness High-Fracture-Toughness B4C-TiB2 Composite Produced by Reactive Hot Pressing. J. of Materi Eng and Perform 32, 7225–7233 (2023). https://doi.org/10.1007/s11665-022-07660-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07660-0