Abstract

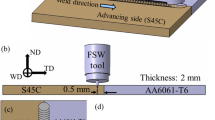

In the present research work, dissimilar metal joints of nickel-based superalloy (IN718) and low-alloy steel (EN24) round bars were carried out by using continuous drive friction welding. The joining of specimens was performed by varying friction time in the range of 2-10 s and kee** other welding parameters (friction pressure, 50 bar; upset pressure, 80 bar; upset time, 3 s; and rotational speed, 1400 rpm) constant. The main focus is to understand the characteristics of weld interface (WI), burn-off length and mechanical behavior of weld samples. It is noteworthy that significant changes in the microstructure caused variation in hardness across the weld interface. Moreover, it was observed that burn-off length increased linearly from 4.2 to 12.9% with increasing friction time. The tensile test results revealed that joint efficiency ~ 100% can be achievable by selecting the appropriate parameters.

Similar content being viewed by others

References

S.D. Meshram, T. Mohandas, and G. Madhusudhan Reddy, Friction Welding of Dissimilar Pure Metals, J. Mater. Process. Technol., 2007, 184, p 330–337.

M. Anitha, C. Majumder, V. Saravanan, and S. Rajakumar, Microstructural Characterization and Mechanical Properties of Friction-Welded IN718 and SS410 Dissimilar Joint, Metallogr. Microstruct. Anal., 2018, 7, p 277–287.

M.J. Donachie and S.J. Donachie, Superalloys: A Technical Guide, ASM International, Helsinki, 2002.

J. Woolman and R.A. Mottram, The Mechanical and Physical Properties of the British Standard EN Steels (BS 970–1955), EN 40 to EN 363, Elsevier, Amsterdam, 2013.

V. Ajay, N. Kishore Babu, M. Ashfaq, T. Mahesh Kumar, and K. Vamsi Krishna, A Review on Rotary and Linear Friction Welding of Inconel Alloys, Trans. IIM, 2021, 74, p 1–16.

J.C. Lippold, S.D. Kiser, and J.N. Du Pont, Welding Metallurgy and Weldability of Nickel-Base Alloys, Wiley, Hoboken, New Jersey, 2009.

W. Li, A. Vairis, M. Preuss, and T. Ma, Linear and Rotary Friction Welding Review, Int. Mater. Rev., 2016, 61(2), p 71–100.

V.T. Gaikwad, M.K. Mishra, V.D. Hiwarkar, and R.K.P. Singh, Microstructure and Mechanical Properties of Friction Welded Carbon Steel (EN24) and Nickel-based Superalloy (IN718), Int. J. Miner. Metall. and Mater., 2021, 28, p 111–119.

H.C. Dey, M. Ashfaq, A.K. Bhaduri, and K. Prasad Rao, Joining of Titanium to 304L Stainless Steel by Friction Welding, J. Mater. Process. Technol., 2009, 209, p 5862–5870.

J.S. Tiley, D.W. Mahaffey, T. Alam, T. Rojhirunsakool, O. Senkov, T. Parthasarthy, and R. Banerjee, Strengthening Mechanisms in an Inertia Friction Welded Nickel-Base Superalloy, Mater. Sci. Eng. A, 2016, 662, p 26–35.

R. Damodaram, S.G.S. Raman, and K.P. Rao, Microstructure and Mechanical Properties of Friction Welded Alloy 718, Mater. Sci. Eng. A, 2013, 560, p 781–786.

W. Hongjie, K. Ikeuchi, M. Aritoshi, M. Takahashi, and A. Ikeda, Joint Strength of Inconel 718 Alloy and its Improvement by Post-Weld Heat Treatment-Joint Performance and its Controlling Factors in Friction Welding of Inconel 718 Alloy, Weld. Int., 2009, 23, p 679–686.

S.V. Lalam, G.M. Reddy, T. Mohandas, M. Kamaraj, and B.S. Murty, Continuous Drive Friction Welding of Inconel 718 and EN24 Dissimilar Metal Combination, Mater. Sci. Technol., 2009, 25, p 851–861.

P. Li, J. Li, M. Salman, L. Liang, J. **ong, and F. Zhang, Effect of Friction Time on Mechanical and Metallurgical Properties of Continuous Drive Friction Welded Ti6Al4V/SUS321 Joints, Mater. Des., 2014, 56, p 649–656.

D. Meshram Suresh and G. Madhusudhan Reddy, Friction Welding of AA6061 to AISI 4340 Using Silver Interlayer, Def. Technol., 2015, 11, p 292–298.

O. Tomo, K. Miyoshi, T. Matsumura, T. Imai, and K. Saida, Improvement of Joint Strength in Dissimilar Friction Welding of Ti-6Al-4V Alloy to Type -718 Nickel-Based Alloy Using the Au–Ni Interlayer, Sci. Technol. Weld. Join., 2019, 24, p 327–333.

J.T. Yeom, J.H. Park, J.W. Lee, and N.K. Park, Characterization of Friction Welding for IN713LC and AISI 4140 Steel, Mater. Sci. Forum, 2004, 449, p 53–56.

V.T. Gaikwad, V.D. Hiwarkar, V.P. Pawar, and R.K.P. Singh, Microstructure Characterization and Evaluation of Mechanical Properties for Friction Welded EN-24 Alloy Steel, Contributed Papers From Materials Science and Technology Oct 14–18, (Columbus, Ohio, USA, 2018), p 822

C. Billel, D. Miroud, R. Badji, P. Hvizdos, M. Fides, T. Csanadi, B. Belkessa, and M. Tata, Microstructure and Mechanical Behavior of Dissimilar AISI 304L/WC-Co Cermet Rotary Friction Welds, Mater. Sci. Eng. A, 2019, 758, p 36–46.

L. Huihong, Yo. Aoki, Y. Aoki, K. Ushioda, and H. Fujii, Principle for Obtaining High Joint Quality in Dissimilar Friction Welding of Ti-6Al-4V Alloy and SUS316L Stainless Steel, J. Mater. Sci. Technol., 2020, 46, p 211–224.

Z. Changqing, S. Wang, D. Luo, W. Shi, X. Liu, G. Cui, B. Chen, Z. **n, and Z. Rui, Study of the Mechanical Properties and Microstructures of Conical Joints for Aluminum/Steel Continuous Drive Friction Welding, J. Manuf. Process., 2021, 67, p 241–252.

Acknowledgments

The authors gratefully acknowledge to Kalyani Centre for Technology & Innovation (KCTI), Bharat Forge Ltd, Pune, and Department of Scientific and Industrial Research (DSIR), Govt. of India, for providing financial funding, laboratory and library facilities. The authors would like to express special thanks and gratitude to review committee of Bharat Forge Ltd, Pune, for granting the permission to publish this research work and also grateful to Mr. Vinayak Pawar and Mr. Santosh Dhage for their support in various aspects for this study. Also, the authors would like thank to Mr. Yatin Tambe, Director of Friction Welding Technologies Pvt. Ltd., Pune, for providing friction welding facilities.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gaikwad, V.T., Mishra, M.K., Hiwarkar, V.D. et al. Role of Friction Time on the Joint Characteristics of Continuous Drive Friction-Welded Inconel 718 and EN24 Steel. J. of Materi Eng and Perform 32, 1660–1670 (2023). https://doi.org/10.1007/s11665-022-07239-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07239-9