Abstract

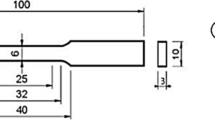

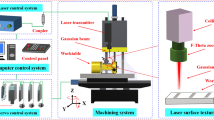

In this work, 316L austenitic stainless steel (ASS) was subjected to laser surface texturing to improve its tribological performance. The effects of surface texture parameters and service conditions on the tribological performance of laser-surface-textured 316L ASS were investigated through Taguchi’s orthogonal arrays. Four main factors were designed in the orthogonal array, namely texture diameter, texture interval, load, and sliding speed. Each factor was with three levels. The comprehensive scoring method was used to analyze the influence of factors and levels on the signal-to-noise ratios and the mean values of the corresponding indicators (wear rate and friction coefficient). Meanwhile, the significance of each factor on the response variable was calculated by analysis of variance (ANOVA). The results indicated that the order in which factors affect the tribological performance was as follows: interval>load>diameter>speed and the optimal parameter combination was 400 μm (diameter), 1200 μm (interval), 10 N (load), and 1500 r/min (speed). The interval had a greater influence of 29.88%, the load influenced 21.54%, and the diameter influenced 8.65%. Finite element analysis results showed that the optimized parameter combination obtained the minimum surface stress. With the increase in the texture interval, the surface stress decreased gradually.

Similar content being viewed by others

References

R. Meng, J.X. Deng, R. Duan, Y.Y. Liu, and G.L. Zhang, Modifying Tribological Performances of AISI 316 Stainless Steel Surfaces by Laser Surface Texturing and Various Solid Lubricants, Opt. Laser Technol., 2019, 109, p 401–411.

Y.T. Shang, Y.P. Yuan, D.F. Li, Y.S. Li, and J.M. Chen, Effects of scanning Speed on in Vitro Biocompatibility of 316L Stainless Steel Parts Elaborated by Selective Laser Melting, Int. J. Adv. Manuf. Technol., 2017, 92, p 4379–4385.

L. Zhang, N. Lin, J. Zou, X. Lin, Z. Liu, S. Yuan, Y. Yu, Z. Wang, Q. Zeng, W. Chen, L. Tian, L. Qin, R. **e, B. Li, Z. Wang, B. Tang, and Y. Wu, Super-hydrophobicity and Corrosion Resistance of Laser Surface Textured AISI 304 Stainless Steel Decorated with Hexadecyltrimethoxysilane (HDTMS), Opt. Laser Technol., 2020, 127, p 106146.

X.M. He, X.B. Liu, M.D. Wang, M.S. Yang, S.H. Shi, G.Y. Fu, and S.F. Chen, Elevated Temperature Dry Sliding Wear Behavior of Nickel-Based Composite Coating on Austenitic Stainless Steel Deposited by a Novel Central Hollow Laser Cladding, Appl. Surf. Sci., 2011, 258, p 535–541.

L.P. Ward, K.P. Purushotham, and R.R. Manory, MEVVA Ion Implantation of TiCN Coatings; Structural and Tribological Properties, Nucl. Instrum. Meth. B., 2019, 449, p 40–48.

K. Zhang, J. Deng, S. Lei, and X. Yu, Effect of Micro/Nano-Textures and Burnished MoS2 Addition on the Tribological Properties of PVD TiAlN Coatings against AISI 316 stainless Steel, Surf. Coat. Tech., 2016, 291, p 382–395.

E. Liu, Y. Zhang, X. Wang, Z. Zeng, H. Du, and H. Qin, Tribocorrosion Behaviors of Thermal Spraying WC/Ni60 Coated 316L Stainless Steel in Artificial Seawater, Ind. Lubr. Tribol., 2019, 71, p 741–748.

N. Lin, L. Zhang, J. Zou, Q. Liu, S. Yuan, L. Zhao, Y. Yu, Z. Liu, Q. Zeng, X. Liu, Z. Wang, B. Tang, and Y. Wu, A Combined Surface Treatment of Surface Texturing-Double Glow Plasma Surface Titanizing on AISI 316 Stainless Steel to Combat Surface Damage: Comparative Appraisals of Corrosion Resistance and Wear Resistance, Appl. Surf. Sci., 2019, 493, p 747–765.

X.B. Liu, C. Zheng, Y.F. Liu, J.W. Fan, M.S. Yang, X.M. He, M.D. Wang, H.B. Yang, and L.H. Qi, A Comparative Study of Laser Cladding High Temperature Wear-Resistant Composite Coating with the Addition of Self-lubricating WS2 and WS2/(Ni-P) Encapsulation, J. Mater. Process Tech., 2013, 213, p 51–58.

X.B. Liu, H.Q. Liu, Y.F. Liu, X.M. He, C.F. Sun, M.D. Wang, H.B. Yang, and L.H. Qi, Effects of Temperature and Normal Load on Tribological Behavior of Nickel-Based High Temperature Self-Lubricating Wear-Resistant Composite Coating, Compos. Part B-Eng., 2013, 53, p 347–354.

M.S. Yang, X.B. Liu, J.W. Fan, X.M. He, S.H. Shi, G.Y. Fu, M.D. Wang, and S.F. Chen, Microstructure and Wear Behaviors of Laser Clad NiCr/Cr3C2-WS2 High Temperature Self-Lubricating Wear-Resistant Composite Coating, Appl. Surf. Sci., 2012, 258, p 3757–3762.

C.S. Ouyang, X.B. Liu, Y.S. Luo, J. Liang, M. Wang, and D.Q. Chen, Preparation and High Temperature Tribological Properties of Laser In-Situ Synthesized Self-Lubricating Composite Coating on 304 Stainless Steel, J. Mater. Res. Technol., 2020, 9, p 7034–7046.

C. Gachot, A. Rosenkranz, S.M. Hsu, and H.L. Costa, A Critical Assessment of Surface Texturing for Friction and Wear Improvement, Wear, 2017, 372, p 21–41.

N.M. Lin, D.L. Li, J.J. Zou, R.Z. **e, Z.H. Wang, and B. Tang, Surface Texture-Based Surface Treatments on Ti6Al4V Titanium Alloys for Tribological and Biological Applications: A Mini Review, Materials, 2018, 11, p 487–514.

I. Etsion and E. Sher, Improving Fuel Efficiency with Laser Surface Textured Piston Rings, Tribol. Int., 2009, 42, p 542–547.

M.S. Suh, Y.H. Chae, S.S. Kim, T. Hinoki, and A. Kohyama, Effect of Geometrical Parameters in Micro-Grooved Crosshatch Pattern under Lubricated Sliding Friction, Tribol. Int., 2010, 43, p 1508–1517.

B.F. He, J. Petzing, P. Webb, and R. Leach, Improving Copper Plating Adhesion on Glass Using Lase Machining Techniques and Areal Surface Texture Parameters, Opt. Laser. Eng., 2015, 75, p 39–47.

L.R.R. da Silva and H.L. Costa, Tribological Behavior of Gray Cast Iron Textured by Maskless Electrochemical Texturing, Wear, 2017, 376, p 1601–1610.

Z.K. Li, J.C. Bai, and J.J. Tang, Micro-EDM Method to Fabricate Three-Dimensional Surface Textures Used as SERS-Active Substrate, Appl. Surf. Sci., 2018, 458, p 810–818.

S. Xu, S.O.J. An, D. Atsushi, and S. Castagne, Development of Low-Cost Deformation-Based Micro Surface Texturing System for Friction Reduction, Int. J. Precis. Eng. Manuf., 2016, 17, p 1059–1065.

X. Su, L.P. Shi, W. Huang, and X.L. Wang, A Multi-Phase Micro-Abrasive Jet Machining Technique for the Surface Texturing of Mechanical Seals, Int. J. Adv. Manuf. Technol., 2016, 86, p 2047–2054.

H.L. Costa and I.M. Hutchings, Some Innovative Surface Texturing Techniques for Tribological Purposes. Proc. Inst, Mech. Eng. Part J. -J. Eng. Tribol., 2014, 229, p 429–448.

B. Podgornik, L.M. Vilhena, M. Sedlacek, Z. Rek, and I. Zun, Effectiveness and Design of Surface Texturing for Different Lubrication Regimes, Meccanica, 2012, 47, p 1613–1622.

Y.C. Guan, F.F. Luo, G.C. Lim, M.H. Hong, H.Y. Zheng, and B.J. Qi, Fabrication of Metallic Surfaces with Long-Term Superhydrophilic Property Using One-Stop Laser Method, Mater. Des., 2015, 78, p 19–24.

A. Ghiotti, S. Bruschi, F. Medea, and A. Hamasaiid, Tribological Behavior of High Thermal Conductivity Steels for Hot Stam** Tools, Tribol. Int., 2016, 97, p 412–422.

D.Q. He, S.X. Zheng, J.B. Pu, G.G. Zhang, and L.T. Hu, Improving Tribological Properties of Titanium Alloys by Combining Laser Surface Texturing and Diamond-Like Carbon Film, Tribol. Int., 2015, 82, p 20–27.

A. Siddiqui and A.K. Dubey, Recent Trends in Laser Cladding and Surface Alloying, Opt. Laser Technol., 2021, 134, p 106619.

D.Y. Zhang, F.F. Zhao, Y. Li, P.Y. Li, Q.F. Zeng, and G.N. Dong, Study on Tribological Properties of Multi-Layer Surface Texture on Babbitt Alloys Surface, Appl. Surf. Sci., 2016, 390, p 540–549.

D.Z. Segu and P. Hwang, Friction Control by Multi-Shape Textured Surface under Pin-on-Disc Test, Tribol. Int., 2015, 91, p 111–117.

D.Z. Segu, S.G. Choi, J.H. Choi, and S.S. Kim, The Effect of Multi-Scale Laser Textured Surface on Lubrication Regime, Appl. Surf. Sci., 2013, 270, p 58–63.

J. Hu and H.B. Xu, Friction and Wear Behavior Analysis of the Stainless Steel Surface Fabricated by Laser Texturing Underwater, Tribol. Intl., 2016, 102, p 371–377.

Y.H. Zhong, L. Zheng, Y.H. Gao, and Z.N. Liu, Numerical Simulation and Experimental Investigation of Tribological Performance on Bionic Hexagonal Textured Surface, Tribol. Intl., 2019, 129, p 151–161.

L.J. Yang, Y. Ding, B. Cheng, J.T. He, G.W. Wang, and Y. Wang, Investigations on Femtosecond Laser Modified Micro-Textured Surface with Anti-Friction Property on Bearing Steel GCr15, Appl. Surf. Sci., 2018, 434, p 831–842.

S. Wos, W. Koszela, and P. Pawlus, The Effect of Both Surfaces Textured on Improvement of Tribological Properties of Sliding Elements, Tribol. Intl., 2017, 113, p 182–188.

W. Tang, Y.K. Zhou, H. Zhu, and H.F. Yang, The Effect of Surface Texturing on Reducing the Friction and Wear of Steel under Lubricated Sliding Contact, Appl. Surf. Sci., 2013, 273, p 199–204.

B. Maazinejad, O. Mohammadnia, G.A.M. Ali, A.S.H. Makhlouf, M.N. Nadagouda, M. Sillanpää, A.M. Asiri, S. Agarwal, V.K. Gupta, and H. Sadegh, Taguchi L9 (34) Orthogonal Array Study Based on Methylene Blue Removal by Single-Walled Carbon Nanotubes-Amine: Adsorption Optimization using the Experimental Design Method, Kinetics, Equilibrium and Thermodynamics, J. Mol. Liq., 2020, 298, p 1–8.

L. Han, S. Wang, and C. Zhang, A Partial Lubrication Model Between Valve Plate and Cylinder Block in Axial Piston Pumps, P. I. Mech. Eng. C-J Mec., 2015, 229, p 3201–3217.

J. Zhang, C. Yuan, B. Xu, Q. Chao, Y. Zhu, and X. Huang, Effect of Surface Texture on Wear Reduction of the Tilting Cylinder and the Valve Plate for a High-Speed Electro-Hydrostatic Actuator Pump, Wear, 2018, 414, p 68–78.

Q. Lv, D. Wang, E. Shiju, H. Chen, and B. Hu, Study on the Effects of the Textured Surface to Improve the Performance of Cylinder Block/Valve Plate Interfaces, AIP Adv., 2019, 9, p 045128.

N.M. Lin, Q. Liu, J.J. Zou, D.L. Li, S. Yuan, Z. Wang, and B. Tang, Surface Damage Mitigation of Ti6Al4V Alloy Via Thermal Oxidation for Oil and Gas Exploitation Application: Characterization of the Microstructure and Evaluation of the Surface Performance, RSC Adv., 2017, 7, p 13517–13535.

A. Patnaik, A. Satapathy, S.S. Mahapatra, and R.R. Dash, A Modeling Approach for Prediction of Erosion Behavior of Glass Fiber-Polyester Composites, J. Polym. Res., 2008, 15, p 147–160.

R. Sahoo, B.B. Jha, and T.K. Sahoo, Experimental Study on the Effect of Microstructure on Dry Sliding Wear Behavior of Titanium Alloy Using Taguchi Experimental Design, Tribol. T., 2014, 57, p 216–224.

Y.J. Yang, H.Y. Lin, C. Yang, S.W. Yang, X.S. **a, and Y.J. Luo, Optimization of process parameters of fused deposition modeling based on orthogonal experiment, China Plast., 2019, 33, p 69–75. (in Chinese)

A.F. Yetim, A. Celik, and A. Alsaran, Improving Tribological Properties of Ti6Al4V Alloy with Duplex Surface Treatment, Surf. Coat. Tech., 2010, 205, p 320–324.

A. Biswas and J.D. Majumdar, Surface Characterization and Mechanical Property Evaluation of Thermally Oxidized Ti-6Al-4V, Mater. Charact., 2009, 60, p 513–518.

N.M. Lin, F.Q. **e, X.Q. Wu, and W. Tian, Influence of Process Parameters on Thickness and Wear Resistance of Rare Earth Modified Chromium Coatings on P110 Steel Synthesized by Pack Cementation, J. Rare Earth., 2011, 29, p 396–400.

S. Koksal, F. Ficici, R. Kayikci, and O. Savas, Experimental Optimization of Dry Sliding Wear Behavior of in Situ AlB2/Al Composite Based on Taguchi’s Method, Mater. Design., 2012, 42, p 124–130.

S. Yuan, N.M. Lin, J.J. Zou, X.Z. Lin, Z.Q. Liu, Y. Yu, Z.X. Wang, Q.F. Zeng, W.G. Chen, L.H. Tian, L. Qin, R.Z. **e, B.Q. Li, H.X. Zhang, Z.H. Wang, B. Tang, and Y.C. Wu, In-Situ Fabrication of Gradient Titanium Oxide Ceramic Coating on Laser Surface Textured Ti6Al4V Alloy with Improved Mechanical Property and Wear Performance, Vacuum, 2020, 176, p 1–16.

S. Yuan, N.M. Lin, J.J. Zou, Z.Q. Liu, Z.X. Wang, L.H. Tian, L. Qin, H.X. Zhang, Z.H. Wang, B. Tang, and Y.C. Wu, Effect of Laser Surface Texturing (LST) on Tribological Behavior of Double Glow Plasma Surface Zirconizing Coating on Ti6Al4V Alloy, Surf. Coat. Tech., 2019, 368, p 97–109.

J.D. Guo, Y. Li, H.L. Lu, L.G. Qin, Y. Li, and G.N. Dong, An Effective Method of Edge Deburring for Laser Surface Texturing of Co–Cr–Mo Alloy, Int. J. Adv. Manuf. Technol., 2017, 94, p 1491–1503.

S.H. Kim, S.H. Jeong, T.H. Kim, J.H. Choi, S.H. Cho, B.S. Kim, and S.W. Lee, Effects of Solid Lubricant and Laser Surface Texturing on Tribological Behaviors of Atmospheric Plasma Sprayed Al2O3-ZrO2 Composite Coatings, Ceram. Int., 2017, 43, p 9200–9206.

M. Sedlacek, B. Podgornik, A. Ramalho, and D. Cesnik, Influence of Geometry and the Sequence of Surface Texturing Process on Tribological Properties, Tribol. Int., 2017, 115, p 268–273.

S.S. Kim, H.G. Lee, and D.G. Lee, Tribological Behaviors of Carbon Composite Grooved Surfaces, Compos. Struct., 2005, 71, p 238–245.

N.M. Lin, Q. Liu, J.J. Zou, J.W. Guo, D.L. Li, S. Yuan, Y. Ma, Z. Zhang, Z. Wang, and B. Tang, Surface Texturing-Plasma Nitriding Duplex Treatment for Improving Tribological Performance of AISI 316 Stainless Steel, Materials, 2016, 9, p 875–900.

Y.Q. **ng, J.X. Deng, X.T. Feng, and S. Yu, Effect of Laser Surface Texturing on Si3N4/TiC Ceramic Sliding against Steel under Dry Friction, Mater. Design., 2013, 52, p 234–245.

L.B. Lu, Z. Zhang, Y.C. Guan, and H.Y. Zheng, Comparison of the Effect of Typical Patterns on Friction and Wear Properties of Chromium Alloy Prepared by Laser Surface Texturing, Opt. Laser Technol., 2018, 106, p 272–279.

U. Sudeep, N. Tandon, and R.K. Pandey, Vibration Studies of Lubricated Textured Point Contacts of Bearing Steels Due to Surface Topographies: Simulations and Experiments, Tribol. Int., 2016, 102, p 265–274.

M.R. Ripoll, B. Podgornik, and J. Vizintin, Finite Element Analysis of Textured Surfaces under Reciprocating Sliding, Wear, 2011, 271, p 952–959.

G.S. Joshi, C. Putignano, C. Gaudiuso, T. Stark, T. Kiedrowski, A. Ancona, and G. Carbone, Effects of the Micro Surface Texturing in Lubricated Non-Conformal Point Contacts, Trib. Int., 2018, 127, p 296–301.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Nos. 51501125 and 51975396), the China Postdoctoral Science Foundation (No. 2016M591415), the Aeronautical Science Foundation of China (No. 20200029029001), the Natural Science Foundation of Shanxi Province (No. 201901D111063), the Transformation of Scientific and Technological Achievements Program of Higher Education Institutions in Shanxi (No. 2020CG020) and Research Project Supported by Shanxi Scholarship Council of China (No. 2020-035).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, H., Yuan, S., Lin, N. et al. Application of Taguchi Method Design to Investigate Tribological Performance of Laser-Surface-Textured 316L Austenitic Stainless Steel. J. of Materi Eng and Perform 32, 475–490 (2023). https://doi.org/10.1007/s11665-022-07107-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07107-6