Abstract

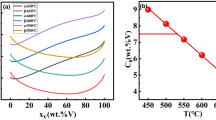

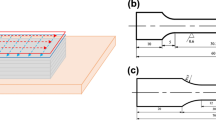

In this paper, the Widmanstätten microstructure in an extruded near-α titanium alloy (Ti-5.5Al-2Zr-1Mo-2.5V) pipe was changed effectively by solid solution treatment at 920 °C for 2 h. The treatment produced intermittent lamellar α and discontinuous α grain boundaries (αGB), and aging at 450 °C for 2 h introduced a high density of nanosized secondary α (αs). The microstructure consisted of the lamellar α, αGB and transformed β demonstrated a good combination of yield strength 1064 MPa and elongation 10.5%. Severe plastic deformation occurred inside the lamellar α during the tensile process, resulting in high-density dislocation tangles and dislocation cells. Furthermore, the stretching imposed on the tensile sample before aging generated dislocations, which piled up near the α/β interface. Thus, a coordinated deformation between lamellar α and transformed β, and the resultant strain partition contributed to an improvement in the ductility. Moreover, dislocation motion was effectively obstructed near the α/β interfaces, which dramatically strengthened the alloy. A solid solution at a middle temperature in the α + β region and aging at a low temperature provided an effective way to improve the strength and ductility simultaneously in titanium alloys with Widmanstätten microstructure.

Similar content being viewed by others

References

R.W. Schutz and H.B. Watkins, Recent Developments in Titanium Alloy Application in the Energy Industry, Mater. Sci. Eng. A, 1998, 243, p 305–315

V.N. Moiseev, Structural Titanium Alloys in Modern Mechanical Engineering, Met. Sci. Heat Treat., 2004, 46, p 115–120

R.D. Kane, S. Craig, and A. Venkatesh, Titanium Alloys for Oil and Gas Service: A Review, in CORROSION 2009, NACE International, Atlanta, Georgia (2009), p. 21

C. Leyens and M. Peters, Titanium and Titanium Alloys: Fundamentals and Applications, Wiley, New York, 2003

R.Z. Li, C. Feng, L. Jiang, and Y.Q. Cao, Research Status and Development of Titanium Alloy Drill Pipes, Mater. Sci. Forum., 2019, 944, p 903–909

J.E. Smith, R.B. Chandler, and P.L. Boster, Titanium Drill Pipe for Ultra-Deep and Deep Directional Drilling, in SPE/IADC Drilling Conference (Society of Petroleum Engineers, Amsterdam, Netherlands, 2001), p. 14

J.E. Smith, R.W. Schutz, and E.I. Bailey. Development of Titanium Drill Pipe for Short Radius Drilling, in IADC/SPE Drilling Conference (Society of Petroleum Engineers, New Orleans, Louisiana, 2000), p. 11

M. Jellison and N. GrantPrideco, Lightweight, Ultra-High-Strength Drill Pipe May Meet Demands of ERD, Critical Deep Drilling, Drill. Contract., 2009, 3, p 53–56

R. Gaur, R.K. Gupta, V. AnilKumar, and S.S. Banwait, Effect of Cold Rolling and Heat Treatment on Microstructure and Mechanical Properties of Ti-4Al-1Mn Titanium Alloy, J. Mater. Eng. Perform., 2018, 27, p 3217–3233

Y. Yu, S. Hui, W. Ye, and B. **ong, Mechanical Properties and Microstructure of an α + β Titanium Alloy with High Strength and Fracture Toughness, Rare Met., 2009, 28, p 346–349

P.F. Gao, G. Qin, X.X. Wang, Y.X. Li, M. Zhan, G.J. Li, and J.S. Li, Dependence of Mechanical Properties on the Microstructural Parameters of TA15 Titanium Alloy with Tri-Modal Microstructure, Mater. Sci. Eng. A, 2019, 739, p 203–213

P. Guo, Y. Zhao, W. Zeng, and J. Liu, Effect of Microstructure on the Fatigue Crack Propagation Behavior of TC4-DT Titanium Alloy, J. Mater. Eng. Perform., 2015, 24, p 1865–1870

Z.N. Lei, P.F. Gao, H.W. Li, Y. Cai, Y.X. Li, and M. Zhan, Comparative Analyses of the Tensile and Damage Tolerance Properties of Tri-Modal Microstructure to Widmanstätten and Bimodal Microstructures of TA15 Titanium Alloy, J. Alloys Compd., 2019, 788, p 831–841

C. Li, J. Chen, W. Li, J.J. He, W. Qiu, Y.J. Ren, J.L. Chen, and J.H. Chen, Study on the Relationship Between Microstructure and Mechanical Property in a Metastable β Titanium Alloy, J. Alloys Compd., 2015, 627, p 222–230

A. Gheysarian and M. Abbasi, The Effect of Aging on Microstructure, Formability and Springback of Ti-6Al-4V Titanium Alloy, J. Mater. Eng. Perform., 2017, 26, p 374–382

A.P. Mouritz, Titanium Alloys for Aerospace Structures and Engines, Introduction to Aerospace Materials, Woodhead Publishing, 2012, p 202–223

G. Lütjering and J.C. Williams, Titanium, Springer, Berlin, 2007, p 227–229

Y. Chong, G. Deng, S. Gao, J. Yi, A. Shibata, and N. Tsuji, Yielding Nature and Hall-Petch Relationships in Ti-6Al-4V Alloy with Fully Equiaxed and Bimodal Microstructures, Scr. Mater., 2019, 172, p 77–82

H. Wu, Z. Sun, J. Cao, and Z. Yin, Microstructure and Mechanical Behavior of Heat-Treated and Thermomechanically Processed TA15 Ti Alloy Composites, J. Mater. Eng. Perform., 2019, 28, p 788–799

I. Weiss and S.L. Semiatin, Thermomechanical Processing of Alpha Titanium Alloys: An Overview, Mater. Sci. Eng. A, 1999, 263, p 243–256

G. Lütjering, Influence of Processing on Microstructure and Mechanical Properties of (α + β) Titanium Alloys, Mater. Sci. Eng. A., 1998, 243, p 32–45

J. Fan, J.S. Li, H. Kou, K. Hua, and B. Tang, The Interrelationship of Fracture Toughness and Microstructure in a New Near β Titanium Alloy Ti-7Mo-3Nb-3Cr-3Al, Mater. Charact., 2014, 96, p 93–99

J.D. Paramore, Z.Z. Fang, P. Sun, M. Koopman, K.S.R. Chandran, and M. Dunstan, A Powder Metallurgy Method for Manufacturing Ti-6Al-4V with Wrought-Like Microstructures and Mechanical Properties Via Hydrogen Sintering and Phase Transformation (HSPT), Scr. Mater., 2015, 107, p 103–106

H.Z. Niu, H.R. Zhang, Q.Q. Sun, and D. Zhang, Breaking Through the Strength-Ductility Trade-Off Dilemma in Powder Metallurgy Ti 6Al 4V Titanium Alloy, Mater. Sci. Eng. A, 2019, 754, p 361–369

Y. Chen, Z. Du, S. **ao, L. Xu, and J. Tian, Effect of Aging Heat Treatment on Microstructure and Tensile Properties of a New β High Strength Titanium Alloy, J. Alloys Compd., 2014, 586, p 588–592

S.A. Mantri, D. Choudhuri, A. Behera, J.D. Cotton, N. Kumar, and R. Banerjee, Influence of Fine-Scale Alpha Precipitation on the Mechanical Properties of the Beta Titanium Alloy Beta-21S, Metall. Mater. Trans. A., 2015, 46, p 2803–2808

K. Yue, L. Jianrong, Z. Shaoxiang, W. Lei, W. Qingjiang, and Y. Rui, Origins of Different Tensile Behaviors Induced by Cooling Rate in a Near Alpha Titanium Alloy Ti65, Materialia, 2018, 1, p S603383428

S.A. Mantri, D. Choudhuri, T. Alam, G.B. Viswanathan, J.M. Sosa, H.L. Fraser, and R. Banerjee, Tuning the Scale of α Precipitates in β-Titanium Alloys for Achieving High Strength, Scr. Mater., 2018, 154, p 139–144

M.T. Jia, D.L. Zhang, B. Gabbitas, J.M. Liang, and C. Kong, A Novel Ti-6Al-4V Alloy Microstructure with Very High Strength and Good Ductility, Scr. Mater., 2015, 107, p 10–13

F. Geng, M. Niinomi, and M. Nakai, Observation of Yielding and Strain Hardening in a Titanium Alloy Having High Oxygen Content, Mater. Sci. Eng. A, 2011, 528, p 5435–5445

W.Y. Guo, H. **ng, J. Sun, X.L. Li, J.S. Wu, and R. Chen, Evolution of Microstructure and Texture during Recrystallization of the Cold-Swaged Ti-Nb-Ta-Zr-O Alloy, Met. Mater. Trans. A., 2008, 39, p 672–678

Y. Okazaki, Y. Ito, A. Ito, and T. Tateishi, Effect of Alloying Elements on Mechanical Properties of Titanium Alloys for Medical Implants, Mater. Trans. JIM, 1993, 34, p 1217–1222

G.C. Obasi, S. Birosca, D.G. Leo Prakash, J.Q. Da Fonseca, and M. Preuss, The Influence of Rolling Temperature on Texture Evolution and Variant Selection During α → β→ α Phase Transformation in Ti-6Al-4V, Acta Mater., 2012, 60, p 6013–6024

Z. Sun, H. Wu, J. Sun, and C. **g, Evolution of Lamellar α Phase During Two-Phase Field Heat Treatment in TA15 Alloy, Int. J. Hydrog. Energy, 2017, 42, p 20849–20856

H. Wu, Z. Sun, J. Cao, and Z. Yin, Formation and Evolution of Tri-Modal Microstructure During Dual Heat Treatment for TA15 Ti-Alloy, J. Alloys Compd., 2019, 786, p 894–905

Z. Zhao, J. Chen, H. Tan, G. Zhang, X. Lin, and W. Huang, Achieving Superior Ductility for Laser Solid Formed Extra Low Interstitial Ti-6Al-4V Titanium Alloy Through Equiaxial Alpha Microstructure, Scr. Mater., 2018, 146, p 187–191

X. Gao, W. Zeng, Y. Wang, Y. Long, S. Zhang, and Q. Wang, Evolution of Equiaxed Alpha Phase During Heat Treatment in a Near Alpha Titanium Alloy, J. Alloys Compd., 2017, 725, p 536–543

Z. Du, S. **ao, L. Xu, J. Tian, F. Kong, and Y. Chen, Effect of Heat Treatment on Microstructure and Mechanical Properties of a New β High Strength Titanium Alloy, Mater. Des., 2014, 55, p 183–190

Y. Zhang, J.P. Liu, S.Y. Chen, X. **e, P.K. Liaw, K.A. Dahmen, J.W. Qiao, and Y.L. Wang, Serration and Noise Behaviors in Materials, Prog. Mater. Sci., 2017, 90, p 358–460

W.C.P. ASTM International. ASTM B861 - 14 Standard Specification for Titanium and Titanium Alloy Seamless Pipe (2014), pp. B814–B861

Q.Y. Sun and H.C. Gu, Tensile and Low-Cycle Fatigue Behavior of Commercially Pure Titanium and Ti-5Al-2.5Sn Alloy at 293 and 77 K, Mater. Sci. Eng. A., 2001, 316, p 80–86

H.F. Lu, K.Y. Luo, L.J. Wu, C.Y. Cui, and J.Z. Lu, Effects of Service Temperature on Tensile Properties and Microstructural Evolution of CP Titanium Subjected to Laser Shock Peening, J. Alloys Compd., 2019, 770, p 732–741

S. Zherebtsov, E. Kudryavtsev, S. Kostjuchenko, S. Malysheva, and G. Salishchev, Strength and Ductility-Related Properties of Ultrafine Grained Two-Phase Titanium Alloy Produced by Warm Multiaxial Forging, Mater. Sci. Eng. A, 2012, 536, p 190–196

W. Lee, T. Chen, and H. Hwang, Impact Response and Microstructural Evolution of Biomedical Titanium Alloy Under Various Temperatures, Metall. Mater. Trans. A., 2008, 2008(39), p 1435–1448

M. Wan, Y. Zhao, W. Zeng, and G. Cai, Effects of Cold Pre-Deformation on Aging Behavior and Mechanical Properties of Ti-1300 Alloy, J. Alloys Compd., 2015, 619, p 383–388

Z. Lincai, D. **aoming, Y. Wei, Z. Man, and S. Zhenya, Effect of Prestrain on Precipitation Behaviors of Ti-2.5Cu Alloy, High Temp. Mater. Process., 2017, 37, p 487–493

W. Zhu, J. Lei, Z. Zhang, Q. Sun, W. Chen, L. **ao, and J. Sun, Microstructural Dependence of Strength and Ductility in a Novel High Strength β Titanium Alloy with Bi-Modal Structure, Mater. Sci. Eng. A, 2019, 762, p 138086

A.H. Rosenberger, A. Madsen, and H. Ghonem, Aging Effects on the Creep Behavior of the Near-Alpha Titanium Alloy Ti-1100, J. Mater. Eng. Perform., 1995, 4, p 182–187

E.O. Hall, The Deformation and Ageing of Mild Steel: III, Discussion of Results, Proc. Phys. Soc. Sect. B., 1951, 64, p 747–753

X. Wen, M. Wan, C. Huang, Y. Tan, M. Lei, Y. Liang, and X. Cai, Effect of Microstructure on Tensile Properties, Impact Toughness and Fracture Toughness of TC21 Alloy, Mater. Des., 2019, 180, p 107898

Z.X. Zhang, S.J. Qu, A.H. Feng, and J. Shen, Achieving Grain Refinement and Enhanced Mechanical Properties in Ti-6Al-4V Alloy Produced by Multidirectional Isothermal Forging, Mater. Sci. Eng. A, 2017, 692, p 127–138

J. Málek, F. Hnilica, J. Veselý, B. Smola, and R. Medlín, The Effect of Annealing Temperature on the Properties of Powder Metallurgy Processed Ti-35Nb-2Zr-0.5O Alloy, J. Mech. Behav. Biomed., 2017, 75, p 252–261

P. Luo, D.T. McDonald, W. Xu, S. Palanisamy, M.S. Dargusch, and K. **a, A Modified Hall-Petch Relationship in Ultrafine-Grained Titanium Recycled from Chips by Equal Channel Angular Pressing, Scr. Mater., 2012, 66, p 785–788

Z. Wang, Cyclic Deformation Response of Planar-Slip Materials and a New Criterion for the Wavy-to-Planar-Slip Transition, Philos. Mag., 2004, 84, p 351–379

D. Caillard, M. Gaumé, and F. Onimus, Glide and Cross-Slip of a-Dislocations in Zr and Ti, Acta Mater., 2018, 155, p 23–34

C.S.G. Lütjering, Influence of α Layers at β Grain Boundaries on Mechanical Properties of Ti-Alloys, Mater. Sci. Eng. A, 2001, 319, p 393–397

J.W. Foltz, B. Welk, P.C. Collins, H.L. Fraser, and J.C. Williams, Formation of Grain Boundary α in β Ti Alloys: Its Role in Deformation and Fracture Behavior of These Alloys, Metall. Mater. Trans. A, 2011, 42, p 645–650

Acknowledgments

This work was supported by the Project supported by State Key Laboratory of Powder Metallurgy of Central South University and by the National Science and Technology Major Project (2016ZX05020-002), Science and Technology Exploration Project of China National Petroleum Corporation (2018D-5010-08).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wu, G., Feng, C., Liu, H. et al. Fine Secondary α Phase-Induced Strengthening in a Ti-5.5Al-2Zr-1Mo-2.5V Alloy Pipe with a Widmanstätten Microstructure. J. of Materi Eng and Perform 29, 1869–1881 (2020). https://doi.org/10.1007/s11665-020-04715-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04715-y