Abstract

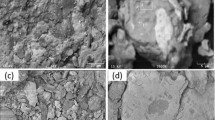

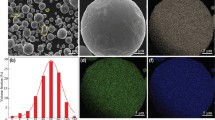

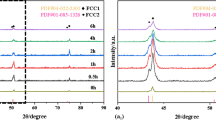

CoCrFeMoTi high-entropy alloy (HEA) was synthesized using mechanical alloying and spark plasma sintering. The corresponding microstructural features and phase composition were compared with those of CoCrFeNi, CoCrFeNiTix (x = 0, 0.3 and 0.5) and CoCrFeNiMox (x = 0, 0.3, 0.5 and 0.85) HEAs. Co, Cr, Fe, Mo and Ti elemental powders were mixed in equiatomic ratio and mechanically alloyed in a planetary ball mill at 300 rpm for up to 80 h. The influence of the milling duration on the evolution of microstructure, constituent phases and morphology was studied. After 40 h of ball milling, two supersaturated BCC solid solution phases were obtained. Milling time increasing resulted in grain refinement and higher solid solution homogenization characterized by a high internal strain. A partial phase transformation from BCC to intermetallic phases when the temperature exceeds 660 °C was revealed. After SPS consolidation, the Vickers hardness was 778 ± 10 HV, in combination with an ultimate shear stress of 216 ± 20 MPa and a yield shear stress of 81 ± 15 MPa for the material sintered at 950 °C and 65 MPa. Further increasing in the sintering temperature resulted in enhanced hardness value of 1600 ± 5 but reduced yield shear stress. The failure analysis revealed a brittle fracture of the synthesized materials.

Similar content being viewed by others

References

D.B. Miracle and O.N. Senkov, A Critical Review of High Entropy Alloys and Related Concepts, Acta Mater., 2017, 122, p 448–511

S.S. Ghazi and K.R. Ravi, Phase-Evolution in High Entropy Alloys: Role of Synthesis Route, Intermetallics, 2016, 73, p 40–42

W. Ji, W. Wang, H. Wang, J. Zhang, Y. Wang, F. Zhang, and Z. Fu, Alloying Behavior and Novel Properties of CoCrFeNiMn High-Entropy Alloy Fabricated by Mechanical Alloying and Spark Plasma Sintering, Intermetallics, 2015, 56, p 24–27

C. Suryanarayana, Mechanical Alloying and Milling, Prog. Mater. Sci., 2001, 46, p 1–184

I. Moravcik, L. Gouvea, J. Cupera, and I. Dlouhy, Preparation and Properties of Medium Entropy CoCrNi/Boride Metal Matrix Composite, J. Alloys Compd., 2018, 748, p 979–988

I. Moravcik, L. Gouvea, V. Hornik, Z. Kovacova, M. Kitzmantel, E. Neubauer, and I. Dlouhy, Synergic Strengthening by Oxide and Coherent Precipitate Dispersions in High-Entropy Alloy Prepared by Powder Metallurgy, Scr. Mater., 2018, 157, p 24–29

W.H. Liu, Z.P. Lu, J.Y. He, J.H. Luan, Z.J. Wang, B. Liu, Y. Liu, M.W. Chen, and C.T. Liu, Ductile CoCrFeNiMox High Entropy Alloys Strengthened by Hard Intermetallic Phases, Acta Mater., 2016, 116, p 332–342

T.T. Shun, L.Y. Chang, and M.H. Shiu, Microstructures and Mechanical Properties of Multiprincipal Component CoCrFeNiTix Alloy, Mater. Sci. Eng. A, 2012, 556, p 170–174

B. Ren, Z.X. Liu, D.M. Li, L. Shi, B. Cai, and M.X. Wang, Effect of Elemental Interaction on Microstructure of CuCrFeNiMn High Entropy Alloy System, J. Alloys Compd., 2010, 493, p 148–153

F. Tian, L.K. Varga, N. Chen, J. Shen, and L. Vitos, Ab Initio Design of Elastically Isotropic TiZrNbMoVx High-Entropy Alloys, J. Alloys Compd., 2014, 599, p 19–25

H. Zare, M. Jahedi, M.R. Toroghinejad, M. Meratian, and M. Knezevic, Compressive, Shear, and Fracture Behavior of CNT Reinforced Al Matrix Composites Manufactured by Severe Plastic Deformation, Mater. Des., 2016, 106, p 112–119

M. Zabihi, M.R. Toroghinejad, and A. Shafyei, Shear Punch Test in Al/Alumina Composite Strips Produced by Powder Metallurgy and Accumulative Roll Bonding, Mater. Sci. Eng. A, 2016, 667, p 383–390

M. Zabihi, M.R. Toroghinejad, and A. Shafyei, Evaluating the Mechanical Behavior of Hot Rolled Al/Alumina Composite Strips Using Shear Punch Test, Mater. Sci. Eng. A, 2014, 618, p 490–495

W. Ji, Z. Fu, W. Wang, H. Wang, J. Zhang, Y. Wang, and F. Zhang, Mechanical Alloying Synthesis and Spark Plasma Sintering Consolidation of CoCrFeNiAl High-Entropy Alloy, J. Alloys Compd., 2014, 589, p 61–66

K.B. Zhang, Z.Y. Fu, J.Y. Zhang, W.M. Wang, S.W. Lee, and K. Niihara, Characterization of Nanocrystalline CoCrFeNiTiAl High-Entropy Solid Solution Processed by Mechanical Alloying, J. Alloys Compd., 2010, 495, p 33–38

W. Chen, Z. Fu, S. Fang, H. **ao, and D. Zhu, Alloying Behavior, Microstructure and Mechanical Properties in a FeNiCrCo0.3Al0.7 High Entropy Alloy, Mater. Des., 2013, 51, p 854–860

J.Y. Huang, Y.D. Yu, Y.K. Wu, D.X. Li, and H.Q. Ye, Microstructure and Nanoscale Composition Analysis of the Mechanical Alloying of FexCu100−x (X = 16, 60), Acta Mater., 1997, 45, p 113–124

B.D. Cullity and S.R. Stock, Elements of x-ray Diffraction, 3rd ed., Pearson, Upper Saddle River, 2001

S. Fang, W. Chen, and Z. Fu, Microstructure and Mechanical Properties of Twinned Al0.5CrFeNiCo0.3C0.2 High Entropy Alloy Processed by Mechanical Alloying and Spark Plasma Sintering, Mater. Des., 2014, 54, p 973–979

K.B. Zhang, Z.Y. Fu, J.Y. Zhang, J. Shi, W.M. Wang, H. Wang, Y.C. Wang, and Q.J. Zhang, Nanocrystalline CoCrFeNiCuAl High-Entropy Solid Solution Synthesized by Mechanical Alloying, J. Alloys Compd., 2009, 485, p L31–L34

C. Sajith Babu, K. Sivaprasad, V. Muthupandi, and J.A. Szpunar, Characterization of Nanocrystalline AlCoCrCuNiFeZn High Entropy Alloy Produced by Mechanical Alloying, Procedia Mater. Sci., 2014, 5, p 1020–1026

O. Maulik and V. Kumar, Synthesis of AlFeCuCrMgx (x = 0, 0.5, 1, 1.7) Alloy Powders by Mechanical Alloying, Mater. Charact., 2015, 110, p 116–125

F.J. Baldenebro-Lopez, J.M. Herrera-Ramirez, S.P. Arredondo-Rea, C.D. Gomez-Esparza, and R. Martinez-Sanchez, Simultaneous Effect of Mechanical Alloying and Arc-Melting Processes in the Microstructure and Hardness of an AlCoFeMoNiTi High-Entropy Alloy, J. Alloys Compd., 2014, 643, p s250–s255

S. Guo and C.T. Liu, Phase Stability in High Entropy Alloys: Formation of Solid-Solution Phase or Amorphous Phase, Mater. Int., 2011, 21, p 433–446

A. Takeuchi and A. Inoue, Classification of Bulk Metallic Glasses by Atomic Size Difference, Heat of Mixing and Period of Constituent Elements and Its Application to Characterization of the Main Alloying Element, Met. Trans., 2005, 46, p 2817–2829

R. Sriharitha, B.S. Murty, and R.S. Kottada, Phase Formation in Mechanically Alloyed AlxCoCrCuFeNi (X = 0.45, 1, 2.5, 5 mol) High Entropy Alloys, Intermetallics, 2013, 32, p 119–126

S. Praveen, B.S. Murty, and S. Kottada Ravi, Phase Evolution and Densification Behavior of Nanocrystalline Multicomponent High Entropy Alloys during Spark Plasma Sintering, JOM, 2013, 65, p 1797–1804

C.C. Tung, J.W. Yeh, T.T. Shun, S.K. Chen, Y.S. Huang, and H.C. Chen, On the Elemental Effect of AlCoCrCuFeNi High-Entropy Alloy System, Mater. Lett., 2007, 61, p 1–5

S. Varalakshmi, G. Appa Rao, M. Kamaraj, and B.S. Murty, Hot Consolidation and Mechanical Properties of Nanocrystalline Equiatomic AlFeTiCrZnCu High Entropy Alloy After Mechanical Alloying, J. Mater. Sci., 2010, 45, p 5158–5163

T.T. Shun, L.Y. Chang, and M.H. Shiu, Microstructure and Mechanical Properties of Multiprincipal Component CoCrFeNiMox Alloys, Mater. Charact., 2012, 70, p 63–67

A.A. Roostaei, A. Zarei-Hanzaki, H.R. Abedi, and M.R. Rokni, An Investigation into the Mechanical Behavior and Microstructural Evolution of the Accumulative Roll Bonded AZ31 Mg Alloy Upon Annealing, Mater. Des., 2011, 32, p 2963–2968

R.K. Guduru, K.A. Darling, R. Kishore, R.O. Scattergood, C.C. Koch, and K.L. Murty, Evaluation of Mechanical Properties Using Shear-Punch Testing, Mater. Sci. Eng. A, 2005, 395, p 307–314

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Torabizadeh, A., Toroghinejad, M.R., Karimzadeh, F. et al. Microstructure and Mechanical Properties of Nanostructured CoCrFeMoTi High-Entropy Alloy Fabricated by Mechanical Alloying and Spark Plasma Sintering. J. of Materi Eng and Perform 28, 7710–7725 (2019). https://doi.org/10.1007/s11665-019-04501-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04501-5