Abstract

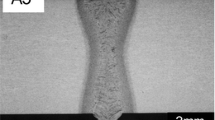

Mechanical Performance of traditional gas-shielded arc welded joints of 700 MPa grade microalloyed C-Mn steel cannot meet service requirements. Laser welding, with its characteristic high energy density, is known to improve the welding performance of experimental steels. In the present study, Nb-Ti microalloyed steel with a thickness of 4.5 mm was welded using a 4 kW fiber laser. The microstructure, precipitation, and mechanical properties of the welded joints were studied. The hardness and tensile strength of the welded joints were higher than those of the base metal (BM). The microstructure of the fusion zone (FZ) and coarse grain heat affected zone (CGHAZ) was lath martensite (LM), while the microstructure of the fine grain HAZ and mixed grain HAZ consisted of ferrite and martensite/austenite islands. Although LM was observed in both the FZ and CGHAZ, the hardness and calculated tensile strength of the FZ were lower than those of the CGHAZ, due to a reduction in solid solution strengthening by element loss and the dissolution of high-hardness precipitates in FZ. Most precipitates such as [(Nb,Ti)C and (Nb,Ti)(C,N)] that were present in the BM were dissolved, which led to an increase in C and N in solid solution in the FZ. Thus, the elastic modulus of the FZ was higher than that of the BM. Similarly, the elastic modulus of the CGHAZ was higher than that of the BM due to the segregation of C and N atoms during the welding process. The toughness of the FZ was superior to that of the BM, and the toughness of the HAZ approached 91% of that of the BM. The change in toughness primarily depended on the microstructural refinement, the increase in the fraction of grains with high misorientation, the residual austenite in the FZ and CGHAZ, and the dissolution of coarse precipitates.

Similar content being viewed by others

References

W. Xu, D. Westerbaan, S.S. Nayak, D.L. Chen, F. Goodwin, E. Biro, and Y. Zhou, Microstructure and Fatigue Performance of Single and Multiple Linear Fiber Laser Welded DP980 Dual-Phase Steel, Mater. Sci. Eng., A, 2012, 553, p 51–58

R. Miranda, A. Costa, L. Quintino, D. Yapp, and D. Iordachescu, Characterization of Fiber Laser Welds in X100 Pipeline Steel, Mater. Des., 2009, 30, p 2701–2707

M. Sokolov, A. Salminen, M. Kuznetsov, and I. Tsibulskiy, Laser Welding and Weld Hardness Analysis of Thick Section S355 Structural Steel, Mater. Des., 2011, 32, p 5127–5131

M.J. Kang and C.H. Kim, Weld Strength of Laser-Welded Hot-Press-Forming Steel, J. Laser Appli., 2012, 24(2), p 022004-1-6

M.J. Zhang, G.Y. Chen, Y. Zhou, and S.H. Liao, Optimization of Deep Penetration Laser Welding of Thick Stainless Steel with a 10 kW Fiber Laser, Mater. Des., 2014, 53, p 568–576

L. Zhang, J.Z. Lu, K.Y. Luo, A.X. Feng, F.Z. Dai, J.S. Zhong, M. Luo, and Y.K. Zhang, Residual Stress, Micro-Hardness and Tensile Properties of ANSI, 304 Stainless Steel Thick Sheet by Fiber Laser Welding, Mater. Sci. Eng., A, 2013, 561, p 136–144

W. Guo, D. Crowther, J.A. Francis, and L. Li, Microstructure and Mechanical Properties of Laser Welded S960 High Strength Steel, Mater. Des., 2015, 85, p 534–548

K.Y. Lin, H.Q. Hang, Z.X. Meng, and C.M. Hui, Influence of Nanoparticle Reinforcements on the Strengthening Mechanisms of an Ultrafine-Grained Dual Phase Steel Containing Titanium, Mater. Des., 2013, 44, p 331–339

P.W. Hsu, F.H. Kao, S.H. Wang, J.R. Yang, H.Y. Chang, Y.M. Wang, and Q.X. Lin, Twinned Formation in Weld Metal of Titanium Bearing Nano Precipitated High Strength Steel, Mater. Chem. Phys., 2012, 136, p 1103–1108

C.Y. Chen, C.C. Chen, and J.R. Yang, Microstructure Characterization of Nanometer Carbides Heterogeneous Precipitation in Ti-Nb and Ti-Nb-Mo Steel, Mater. Charact., 2014, 88, p 69–79

M.P. Phaniraj, Y.M. Shin, J. Lee, N.H. Goo, D.I. Kim, J.Y. Suh, W.S. Jung, J.H. Shim, and I.S. Choi, Development of High Strength Hot Rolled Low Carbon Copper-Bearing Steel Containing Nanometer Sized Carbides, Mater. Sci. Eng., A, 2015, 633, p 1–8

R.D.K. Misra, H. Nathani, J.E. Harmann, and F. Siciliano, Microstructural Evolution in a New 770 MPa Hot Rolled Nb-Ti Microallyed Steel, Mater. Sci. Eng., A, 2005, 394, p 339–352

V.S.A. Challa, W.H. Zhou, R.D.K. Misra, R. OMalley, and S.G. Jansto, The Effect of Coiling Temperature on the Microstructure and Mechanical Properties of a Niobium-Titanium Microalloyed Steel Processed via Thin Slab Casting, Mater. Sci. Eng., A, 2014, 394, p 143–153

J.H. Lee, S.H. Park, H.S. Kwon, G.S. Kim, and C.S. Lee, Laser, Tungsten Inert Gas, and Metal Active Gas Welding of DP780 Steel: Comparison of Hardness, Tensile Properties and Fatigue Resistance, Mater. Des., 2014, 64, p 559–565

X.N. Wang, H.S. Di, C. Zhang, and L.X. Du, X.X Dong, Study of the Weldability of 780 MPa Super-High Strength Heavy-Duty Truck Crossbeam Steel, J. Iron. Steel Res. Int., 2012, 19(6), p 64–69

X.N. Wang, Q. Sun, L.X. Du, and H.S. Di, 700 MPa Grade Steel for Heavy-Duty Truck Development and Carriage Lightweight Design, Rev. Adv. Mater. Sci., 2013, 33, p 187–194

S. Talas, The Assessment of Carbon Equivalent Formulas in Predicting the Properties of Steel Weld Metals, Mater. Des., 2010, 31, p 2649–2653

M. Zhang, X.N. Wang, G.J. Zhu, C.J. Chen, J.X. Hou, S.H. Zhang, and H.M. **g, Effect of Laser Welding Process Parameters on Microstructure and Mechanical Properties on Butt Joint of New Hot-Rolled Nano-Scale Precipitate Strengthen Steel, Acta Metall. Sini. (Engl. Lett.), 2014, 27(3), p 521–529

X.N. Wang, C.J. Chen, H.S. Wang, S.H. Zhang, M. Zhang, and X. Luo, Microstructure Formation and Precipitation in Laser Welding of Microalloyed C-Mn Steel, J. Mater. Process. Technol., 2015, 226, p 106–114

L. Zhang and T. Kannengiesser, Austenite Grain Growth and Microsturcture Control in Simulated Heat Affected Zones of Microalloyed HSLA Steel, Mater. Sci. Eng., A, 2014, 613, p 326–335

Y.M. Li, B.X. Yang, X.H. Cui, C.G. Han, and H.J. Shang, Hardness Control for Base Material and Welded Jointss of 9%–12% Martensite Steel, Therm. Power Gener., 2010, 39, p 57–60

A.G. Grigoryants, I.N. Shiganov, A.l. Misyurov. In: Grigoryants AG, editor. Technological Processes of Laser Welding. Moscow: Bauman Moscow State Technical University; 2006. [Russian]

X.N. Wang, L.X. Du, H.S. Di, H. **e, and D.H. Gu, Effect of Deformation on Continuous Cooling Phase Transformation Behaviors of 780 MPa Nb-Ti Ultra-High Strength Steel, Steel Res. Int., 2011, 82(12), p 1417–1424

S. Kou, Weld. Metall., Wiley, Manhattan, 2002

S. Liu and D.L. Olson, The Role of Inclusions in Controlling HSLA Steel Weld Microstructure, Weld. Res. Suppl., 1986, 65(6), p 139–150

D. Parkes, W. Xu, D. Westerbaan, S.S. Nayak, Y. Zhou, F. Goodwin, S. Bhole, and D.L. Chen, Microstructure and Fatigue Properties of Fiber Laser Welded Dissimilar Joints Between High Strength Low Alloy and Dual-Phase Steels, Mater. Des., 2013, 51, p 665–675

S.S. Nayaka, V.H. BaltazarHernandeza, Y. Okitaa, and Y. Zhou, Microstructure–Hardness Relationship in the Fusion Zone of TRIP Steel Welds, Mater. Sci. Eng., A, 2012, 551, p 73–81

S.H. Kim, D.H. Kang, and T.W. Kim, Fatigue Crack Growth Behavior of the Simulated HAZ of 800 MPa Grade High-Performance Steel, Mater. Sci. Eng., A, 2011, 528, p 2331–2338

N. Yurioka and K. Kojima, A Predictive Formula of Weld Metal Tensile Strength, Q. J. Jp Weldi.Soc., 2004, 22, p 53–60

A.M. Paniagua-Mercado, V.M. Lopez-Hirata, and M.L.S. Munoz, Influence of the Chemical Composition of Flux on the Microstructure and Tensile Properties of Submerged-Arc Welds, J. Mater. Process. Technol., 2005, 169, p 346–351

L.Y. Lan, C.L. Qiu, and D.W. Zhao, Structure and Micromechanical Properties of a Weld Joint Using Steel with Low Sensitivity to Weld Cracking, J. Northeastern Univ. Nat. Sci., 2011, 32(4), p 505–508

Y.J. Chao, J.D. Ward, Jr., and R.G. Sands, Charpy Impact Energy, Fracture Toughness and Ductile–Brittle Transition Temperature of Dual-Phase 590 Steel, Mater. Des., 2007, 28, p 551–557

L. Wang, Mech. Prope. Mater., Northeastern University Press, Shenyang, 2005, p 132–152

I. de Diego-Calderón, M.J. Santofimia, J.M. Molina-Aldareguia, M.A. Monclús, and I. Sabirov, Deformation Behavior of a High Strength Multiphase Steel at Macro- and Micro-Scales, Mater. Sci. Eng., A, 2014, 611, p 201–211

J.G. Speer, F.C. Rizzo Assunção, D.K. Matlock, and D.V. Edmonds, The “Quenching and Partitioning” Process: Background and Recent Progress, Materi. Res., 2005, 8(4), p 417–423

J.S. Byun, J.H. Shim, Y.W. Cho, and D.N. Lee, Non-metallic Inclusion and Intragranular Nucleation of Ferrite in Ti-killed C-Mn Steel, Acta Mater., 2003, 51(6), p 1593–1606

E. Bonnevie, G. Ferriere, A. Ikhlef, D. Kaplan, and J.M. Orain, Morphological Aspects of Martensite–Austenite Constituents in Intercritical and Coarse Grain Heat Affected Zones of Structural Steels, Mater. Sci. Eng., A, 2004, 385, p 352–358

S.M. Hong, E.K. Park, J.J. Park, M.K. Lee, and J.G. Lee, Effect of Nano-sized TiC Particle Addition on Microstructure and Mechanical Properties of SA-106B Carbon Steel, Mater. Sci. Eng., A, 2015, 643, p 37–46

M.R. Akbarpour, E. Salahi, F. Alikhani Hesari, H.S. Kim, and A. Simchi, Effect of Nanoparticle Content on the Microstructural and Mechanical Properties of Nano-SiC Dispersed Bulk Ultrafine-Grained Cu Matrix Composites, Mater. Des., 2013, 52, p 881–887

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (NO. 51775102).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, Q., Nie, XK., Li, Y. et al. Microstructure-Property Correlations in Fiber Laser Welded Nb-Ti Microalloyed C-Mn Steel. J. of Materi Eng and Perform 27, 847–856 (2018). https://doi.org/10.1007/s11665-018-3138-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3138-8