Abstract

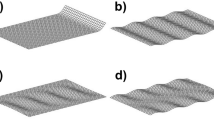

The effects of a roughing pass in hot rolling simulations were assessed in VN and Nb-Ti steels. Continuous cooling phase transformation temperatures, flow curves, softening mechanisms (dynamic transformation DT and dynamic recrystallization DRX), and deformed microstructure morphologies were analyzed. The application of one or more roughing passes eliminates the effects of prior microstructural history and ensures that all stock material experiences equivalent hot working conditions and state of the microalloying elements. It has been shown that roughing in hot simulation has the following positive influences: (1) provide more reliable flow stress data; (2) give greater consistencies and accuracy in analysis of softening mechanisms giving three distinct regimes (DT regime at temperatures below 800 °C, DT/DRX inter-mode regime between 800 and 950 °C and DRX regime for temperatures above 950 °C for VN steel); (3) promotion of softening mechanisms as evidence by low critical strains (\(\varepsilon_{{{\text{c}}\,{\text{DT}}}}\) was within the range 0.08-0.12, while for finishing-only pass, the \(\varepsilon_{{{\text{c}}\,{\text{DT}}}}\) was in the range of 0.11-0.14 at \(\dot{\varepsilon } = 0.1\) s−1); (4) for roughing and finishing schedules, DT was verified to occur at temperatures 117 and 133 °C above \(Ae_{3}\) for VN steel and Nb-Ti steel, respectively, compared to the F-only schedules which showed that DT can only occur at temperatures below the \(Ae_{3}\); (5) RF schedules promoted uniform microstructural morphologies compared to inhomogeneous microstructures realized in F-only schedules.

Similar content being viewed by others

References

D. Samantaray, S. Mandal, and A.K. Bhaduri, A Comparative Study on Johnson Cook, Modified Zerilli-Armstrong and Arrhenius-Type Constitutive Models to Predict Elevated Temperature Flow Behaviour in Modified 9Cr-1Mo Steel, Comput. Mater. Sci., 2009, 47, p 568–576

B. Roebuck, J.D. Lord, M. Brooks, M.S. Loveday, C.M. Sellars, and R.W. Evans, Measurement of Flow Stress in Hot Axisymmetric Compression Tests, Sci. Rev. Mater. High Temp., 2006, 23(2), p 59–83

R. Ebrahimi and E. Shafiei, Mathematical Modeling of Single Peak Dynamic Recrystallization Flow Stress Curves in Metallic Alloys (2012). [Online] Available: http://www.intechopen.com/books/recystallization/mathematical-modelling-of-sinlge-peak-dynamic-recrystallization-flow-stress-curves-in-metallic-alloys. Accessed 30 May 2015

S.K. Rajput, G.P. Chaudhari, and S.K. Nath, Physical Simulation of Hot Deformation of Low-Carbon Ti-Nb Microalloyed Steel and Microstructual Studies, J. Mater. Eng. Perform., 2014, 23(8), p 2930–2942

B. Eghbali, Effect of Strain Rate on the Microstructural Development Through Continuous Dynamic Recrystallization in a Microalloyed Steel, Mater. Sci. Eng. A, 2010, 527, p 3402–3406

H. Beladi and P.D. Hodgson, Effect of Carbon Content on the Recrystallization Kinetics of Nb-Steel, Scr. Mater., 2007, 56, p 1059–1062

P.D. Hodgson and R.K. Gibbs, A Mathematical Model to Predict the Mechanical Properties of Hot Rolled C-Mn and Microalloyed Steels, ISIJ Int., 1992, 32(12), p 1329–1338

P.D. Hodgson, S.H. Zahiri, and J.J. Whale, The Static and Metadynamic Recrystallization Behaviour of an X60 Nb Microalloyed Steel, ISIJ Int., 2004, 44(7), p 1224–1229

S.H. Zahiri, S.M. Byon, S. Kim, Y. Lee, and P.D. Hodgson, Static and Metadynamic Recrystallization of Interstitial Free Steels During Hot Deformation, ISIJ Int., 2004, 44(11), p 1918–1923

B. Eghbali and A. Abdollah-zadeh, Influence of Deformation Temperature on the Ferrite Grain Refinement in a Low Carbon Nb-Ti Microalloyed Steel, J. Mater. Process. Technol., 2006, 180, p 44–48

J.-K. Choi, D.-H. Seo, J.-S. Lee, K.-K. Um, and W.-Y. Choo, Formation of Ultrafine Ferrite by Strain-Induced Dynamic Transformation in Plain Low Carbon Steel, ISIJ Int., 2003, 43(5), p 746–754

H. Dong and X. Sun, Deformation Induced Ferrite Transformation in Low Carbon Steels, Curr. Opin. Solid State Mater. Sci., 2005, 9, p 269–276

H. Mirzadeh and A. Najafizadeh, Prediction of the Critical Condition for Initiation of Dynamic Recrystallization, Mater. Des., 2010, 31, p 1174–1179

C.J. Aranas, T. Nguyen-Minh, R. Grewal, and J.J. Jonas, Flow Softening-Based Formation of Widmanstatten Ferrite in a 0.06% C Steel Deformed Above the Ae3, ISIJ Int., 2015, 55(1), p 300–307

J. Biglou and J.G. Lenard, A Study of Dynamic Recrystallization During Hot Rolling of Microalloyed Steels, Ann. CIRP, 1996, 45(1), p 227–230

S.F. Medina and V. Lopez, Static Recrystallization in Austenite and its Influence on Microstructural Changes in C-Mn Steel and Vanadium Microalloyed Steel at the Hot Strip Mill, ISIJ Int., 1993, 33(5), p 605–614

E.I. Poliak and J.J. Jonas, A One-Parameter Approach to Determining the Critical Conditions for the Initiation of Dynamic Recrystallization, Acta Mater., 1996, 44(1), p 127–136

J.J. Jonas, C. Ghosh, X. Quelennec, and V.V. Basabe, The Critical Strain for Dynamic Transformation in Hot Deformed Austenite, ISIJ Int., 2013, 53(1), p 145–151

C.J. Aranas, R. Grewal, K. Chadha, D. Shahriari, M. Jahazi, and J.J. Jonas, Formation of Widmanstatten Ferrite in a C-Mn Steel at Temperatures High in the Austenite Phase Field, in Proceedings of the International Conference on Solid-Solid Phase Transformations in Inorganic Materials 2015, 2015

C. Ghosh, The Dynamic Transformation of Deformed Austenite at Temperatures Above the Ae3, PhD Thesis, McGill University, Montreal, Canada, 2013

C.J. Aranas, S.F. Rodrigues, R. Grewal, and J.J. Jonas, Ferrite Formation Above the Ae3 Temperature During the Torsion Simulation of Strip Rolling, ISIJ Int., 2015, 55(11), p 2426–2434

J.J. Jonas, C.J. Aranas, and S.F. Rodrigues, Dynamic Transformation During the Torsion Simulation of Plate and Strip Rolling, in Proceedings of the 4th International Conference on Thermo-Mechanical Simulation and Processing of Steel (Ranchi, 2016), pp. 10–12

T. Sakai, A. Belyakov, R. Kaibyshev, H. Miura, and J.J. Jonas, Dynamic and Post-Dynamic Recrystallization Under Hot, Cold and Severe Plastic Deformation Conditions, Prog. Mater Sci., 2014, 60, p 130–207

M.E. Kassner and S.R. Barrabes, New Developments in Geometric Dynamic Recrystallization, Mater. Sci. Eng. A, 2005, 410–411, p 152–155

C. Zheng, N. **ao, L. Hao, D. Li, and Y. Li, Numerical Simulation of Dynamic Strain-Induced Austenite-Ferrite Transformation in a Low Carbon Steel, Acta Mater., 2009, 57, p 2956–2968

Acknowledgments

This work has been performed with funding from the University of Pretoria and technical support from Industrial Minerals and Metals Research Institute (IMMRI). Help from Rorisang Maubane is gratefully acknowledged for providing on-equipment training and technical support on the Bähr 850AD™ and Gleeble 1500™ tests.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chalimba, S.A.J., Mostert, R.J., Stumpf, W.E. et al. Effects of Roughing on Finish Rolling Simulations in Microalloyed Strip Steels. J. of Materi Eng and Perform 26, 5294–5303 (2017). https://doi.org/10.1007/s11665-017-2987-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2987-x