Abstract

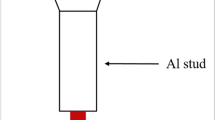

Nanotwinned face-centered-cubic (FCC) metals have gained significant attention recently due to their exceptional mechanical and electrical properties. Among all the FCC metals, Ag has the lowest stacking fault energy, which allows twin formation to easily occur. In this study, Ag films with a thickness of 4 µm were deposited on Si (100) substrates pre-coated with Ti adhesion layers by electron beam evaporation. With ion beam assistance during the evaporation process, highly (111)-textured and high-density nanotwinned Ag films with excellent properties were produced. Both x-ray diffraction (XRD) and electron backscatter diffraction (EBSD) analyses indicate that the Ag film possesses a strong (111) preferred orientation. In addition, statistical measurements from transmission electron microscopy (TEM) images show that the average twin spacing in nanotwinned Ag films with a deposition rate of 1.8 nm/s is only 6.1 nm. However, conventional models based on thermodynamics are insufficient to describe the formation of growth twins in an ion beam-assisted deposition system. Therefore, an ion bombardment stress model is introduced in this work. The results of the mechanism of deformation twinning are also discussed.

Similar content being viewed by others

References

H. Idrissi, B. Wang, M.S. Colla, J.P. Raskin, D. Schryvers, and T. Pardoen, Ultrahigh strain hardening in thin palladium films with nanoscale twins. Adv. Mater. 23(18), 2119 (2011).

B. Wang, H. Idrissi, H. Shi, M.-S. Colla, S. Michotte, J.-P. Raskin, T. Pardoen, and D. Schryvers, Texture-dependent twin formation in nanocrystalline thin Pd films. Scripta Mater. 66(11), 866 (2012).

B. Amin-Ahmadi, H. Idrissi, M. Galceran, M.-S. Colla, J.-P. Raskin, T. Pardoen, S. Godet, and D. Schryvers, Effect of deposition rate on the microstructure of electron beam evaporated nanocrystalline palladium thin films. Thin Solid Films 539, 145 (2013).

K. Han, J. Hirth, and J. Embury, Modeling the formation of twins and stacking faults in the Ag-Cu system. Acta Mater. 49(9), 1537 (2001).

X. Zhang, A. Misra, H. Wang, T. Shen, M. Nastasi, T. Mitchell, J. Hirth, R. Hoagland, and J. Embury, Enhanced hardening in Cu/330 stainless steel multilayers by nanoscale twinning. Acta Mater. 52(4), 995 (2004).

D. Bufford, H. Wang, and X. Zhang, High strength, epitaxial nanotwinned Ag films. Acta Mater. 59(1), 93 (2011).

T. Gray, Elements: A visual exploration of every known atom in the universe (UK: Hachette, 2012).

M.I. Baskes, Modified embedded-atom potentials for cubic materials and impurities. Phys. Rev. B 46(5), 2727 (1992).

DA Porter and KE (2009) Easterling, phase transformations in metals and alloys (revised reprint), CRC press

L. Velasco, M.N. Polyakov, and A.M. Hodge, Influence of stacking fault energy on twin spacing of Cu and Cu-Al alloys. Scripta Mater. 83, 33 (2014).

D. Xu, V. Sriram, V. Ozolins, J.-M. Yang, K.-N. Tu, G.R. Stafford, and C. Beauchamp, In situ measurements of stress evolution for nanotwin formation during pulse electrodeposition of copper. J. Appl. Phys. 105(2), 023521 (2009).

D. Xu, W.L. Kwan, K. Chen, X. Zhang, V. Ozoliņš, and K.-N. Tu, Nanotwin formation in copper thin films by stress/strain relaxation in pulse electrodeposition. Appl. Phys. Lett. 91(25), 254105 (2007).

Y. Liu, D. Bufford, S. Rios, H. Wang, J. Chen, J. Zhang, and X. Zhang, A formation mechanism for ultra-thin nanotwins in highly textured Cu/Ni multilayers. J. Appl. Phys. 111(7), 073526 (2012).

T.-C. Chan, Y.-Z. Chen, Y.-L. Chueh, and C.-N. Liao, Large-scale nanotwins in Cu films/Cu nanowires via stress engineering by a high-energy ion beam bombardment process: growth and characterization. J. Mater. Chem. C 2(46), 9805 (2014).

G. Abadias, E. Chason, J. Keckes, M. Sebastiani, G.B. Thompson, E. Barthel, G.L. Doll, C.E. Murray, C.H. Stoessel, and L. Martinu, Stress in thin films and coatings: Current status, challenges, and prospects. J. Vacuum Sci. Technol. A: Vacuum, Surf., Films 36(2), 020801 (2018).

S. Mayr and R. Averback, Effect of ion bombardment on stress in thin metal films. Phys. Rev. B 68(21), 214105 (2003).

H. Windischmann, An intrinsic stress scaling law for polycrystalline thin films prepared by ion beam sputtering. J. Appl. Phys. 62(5), 1800 (1987).

E.K. McCarthy, A.T. Bellew, J.E. Sader, and J.J. Boland, Poisson’s ratio of individual metal nanowires. Nat. Commun. 5(1), 1 (2014).

S. Kibey, J. Liu, D. Johnson, and H. Sehitoglu, Predicting twinning stress in fcc metals: Linking twin-energy pathways to twin nucleation. Acta Mater. 55(20), 6843 (2007).

Chakartnarodom P, Kongkajun N, and Senthongkaew P, (2015) Application of numerical method and statistical analysis in the integrated intensity calculation of the peaks from the x-ray diffraction (XRD) pattern of α-iron, Key Engineering Materials, 350-354.

Q. Zhao, Y. Deng, N.W. Utomo, J. Zheng, P. Biswal, J. Yin, and L.A. Archer, On the crystallography and reversibility of lithium electrodeposits at ultrahigh capacity. Nature 12(1), 6034 (2021).

P.C. Wu and T.H. Chuang, Evaporation of Ag nanotwinned films on Si substrates with ion beam assistance. IEEE Trans. Comp., Packag. Manuf. Technol. 11(12), 2222 (2021).

V. Sriram, J.-M. Yang, J. Ye, and A.M. Minor, Determining the stress required for deformation twinning in nanocrystalline and ultrafine-grained copper. Jom 60(9), 66 (2008).

W. Abuzaid and H. Sehitoglu, Critical resolved shear stress for slip and twin nucleation in single crystalline FeNiCoCrMn high entropy alloy. Mater Charact 129, 288 (2017).

R.E. Reed-Hill, R. Abbaschian, and R. Abbaschian, Physical metallurgy principles (New York: Van Nostrand, 1973).

Y. Zhu, X. Liao, and X. Wu, Deformation twinning in nanocrystalline materials. Prog. Mater. Sci. 57(1), 1 (2012).

G. Cheng, H. Li, G. Xu, W. Gai, and L. Luo, In situ observation of nanotwins formation through twin terrace growth in pulse electrodeposited Cu films. Sci. Rep. 7(1), 1 (2017).

W. Mason, H. McSkimin, and W. Shockley, Ultrasonic observation of twinning in tin. Phys. Rev. 73(10), 1213 (1948).

L. Lu, Y. Shen, X. Chen, L. Qian, and K. Lu, Ultrahigh strength and high electrical conductivity in copper. Science 304(5669), 422 (2004).

Acknowledgments

This study was sponsored by the Emerging Technology Application Program of the Hsinchu Science Park R & D program of Ag Materials Technology Co., LTD under Grant No. 112AO03A.

Funding

Funding was provided by the Emerging Technology Application Program of the Hsinchu Science Park R & D program of Ag Materials Technology Co., LTD (112AO03A).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chuang, TH., Lin, AY., Chen, YT. et al. Ion Bombardment-Induced Stress Mechanism for the Formation of Ag Nanotwinned Films on Si Substrates. J. Electron. Mater. 53, 2583–2590 (2024). https://doi.org/10.1007/s11664-023-10905-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-023-10905-w