Abstract

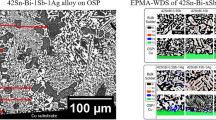

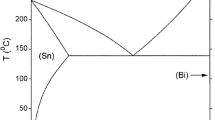

Low-melting-point Sn-Bi solder joints (melting point: 139°C) show remarkable resistance to damage accumulation during aggressive thermal cycling. In this study, we used isothermal aging at 85°C of near eutectic Sn-Bi solder joints to determine the effect of Sb in solid solution and Ag3Sn intermetallic on microstructural evolution and the resulting mechanical properties as a way to explain the thermal cycling behavior. Most importantly, the Sb in solid solution in these alloys resulted in higher strength and improved creep resistance when compared to eutectic Sn-Bi. In contrast to Sn-Pb and Sn-Ag-Cu Pb-free alloys, all the near-eutectic Sn-Bi alloys tested showed significant age hardening. In both the unaged and aged conditions, both Sb and Ag additions individually increased the saturation stress of the eutectic Sn-Bi solder joint, but Ag had a more significant effect. However, when both Sb and Ag were added to eutectic Sn-Bi, the saturation stress was lower than when 1 wt.% Ag alone was added. In terms of relative behavior, the Sb-free 42Sn-Bi-1Ag aged for 250 h had the highest saturation stress of all tested alloys, while as-reflowed eutectic Sn-Bi had the lowest saturation stress. These results suggest that the alloy design strategy for Sn-Ag-Cu alloys, i.e., assuming that the effects of individual alloying elements are additive and independent, is not valid when Sb is added to Sn-Bi low-temperature solder.

Graphical Abstract

Similar content being viewed by others

References

S. Mokler, R. Aspandiar, K. Byrd, O. Chen, and S. Walwadkar, The application of Bi-based solders for low temperature reflow to reduce cost while improving SMT yields in client computing systems. In Proceeding of SMTA International, pp. 318–326 (2016).

M. Mccormack, H.S. Chen, G.W. Kammlott, and S. **, Significantly improved mechanical properties of Bi-Sn solder alloys by Ag-do**. J. Electron. Mater. 26, 954–958 (1997). https://doi.org/10.1007/S11664-997-0281-7.

L. Shen, P. Septiwerdani, and Z. Chen, Elastic modulus, hardness and creep performance of SnBi alloys using nanoindentation. Mater. Sci. Eng. A 558, 253–258 (2012). https://doi.org/10.1016/j.msea.2012.07.120.

K.-W. Moon, W.J. Boettinger, U.R. Kattner, F.S. Biancaniello, and C.A. Handwerker, Experimental and thermodynamic assessment of Sn-Ag-Cu solder alloys. J. Electron. Mater. 29, 1122–1136 (2000). https://doi.org/10.1007/s11664-000-0003-x.

P.J. Shang, Z.Q. Liu, D.X. Li, and J.K. Shang, TEM observations of the growth of intermetallic compounds at the SnBi/Cu interface. J. Electron. Mater. 38, 2579–2584 (2009). https://doi.org/10.1007/S11664-009-0894-0.

F. Wang, Y. Huang, Z. Zhang, and C. Yan, Interfacial reaction and mechanical properties of Sn-Bi solder joints. Materials 10, 920 (2017). https://doi.org/10.3390/ma10080920.

S. Sakuyama, T. Akamatsu, K. Uenishi, and T. Sato, Effects of a third element on microstructure and mechanical properties of eutectic Sn-Bi solder. Trans. Jpn. Inst. Electron. Packag. 2, 98–103 (2009). https://doi.org/10.5104/jiepeng.2.98.

F. Yang, L. Zhang, Z.Q. Liu, S.J. Zhong, J. Ma, and L. Bao, Properties and microstructures of Sn-Bi-X lead-free solders. Adv. Mater. Sci. Eng. 2016 (2016).

J.G. Li, X. Ma, M.B. Zhou, X. Ning, and X.P. Zhang. Effects of Sb addition on the microstructure and mechanical performance of Sn58Bi based alloys and the solder joints. In Proceedings—2018 19th International Conference on Electronic Packaging Technology, ICEPT 2018. Institute of Electrical and Electronics Engineers Inc., pp. 457–461 (2018).

C. Zhang, S.D. Liu, G.T. Qian, J. Zhou, and F. Xue, Effect of Sb content on properties of Sn-Bi solders. Trans. Nonferrous Met. Soc. China (Engl. Ed.) 24, 184–191 (2014). https://doi.org/10.1016/S1003-6326(14)63046-6.

H.N. Fowler, S.X. Tay, J. Blendell, and C.A. Handwerker, Microalloying effects of Sb and Ag on the microstructural evolution of eutectic Sn–Bi alloys. MRS Adv. 2023, 1–5 (2023). https://doi.org/10.1557/S43580-022-00472-3.

S.A. Pl, C.V. Greene, S.Y. Lai, R. Radulescu, H. Fowler, J. Blendell, C. Handwerker, G. Subbarayan, and N. Badwe,. Comparative mechanical behavior of Sn-Bi based low temperature solder alloys under different pretest aging conditions. In 2023 IEEE 73rd Electronic Components and Technology Conference (ECTC), pp. 2218–2222 (2023). https://doi.org/10.1109/ECTC51909.2023.00384.

J.A. Wu, A. Luktuke, and N. Chawla, Surface precipitation and growth of bismuth particles in Sn-Ag-Cu-Bi solder joints. J. Electron. Mater. 52, 801–809 (2023). https://doi.org/10.1007/S11664-022-10126-7.

F. Wang, A. Luktuke, and N. Chawla, Microstructural coarsening and mechanical properties of eutectic Sn-58Bi solder joint during aging. J. Electron. Mater. 50, 6607–6614 (2021). https://doi.org/10.1007/S11664-021-09255-2.

T. Dale, Y. Singh, I. Bernander, G. Subbarayan, C. Handwerker, P. Su, and B. Glasauer, Fatigue life of Sn3.0Ag0.5Cu solder alloy under combined cyclic shear and constant tensile/compressive loads. J. Electron. Packag. Trans. ASME (2020). https://doi.org/10.1115/1.4048109/1086209.

C. Greene. Micro- and Nano-Precision Testing on Low Temperature Solders. Thesis, Purdue University Graduate School (2021).

M. Motalab, Z. Cai, J.C. Suhling, and P. Lall, Determination of Anand constants for SAC solders using stress-strain or creep data. In InterSociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, ITHERM, pp. 910–922 (2012). https://doi.org/10.1109/ITHERM.2012.6231522.

D. Bhate, D. Chan, G. Subbarayan, T.C. Chiu, V. Gupta, and D.R. Edwards, Constitutive behavior of Sn3.8Ag0.7Cu and Sn1.0Ag0.5Cu alloys at creep and low strain rate regimes. IEEE Trans. Compon. Packag. Technol. 31, 622–633 (2008). https://doi.org/10.1109/TCAPT.2008.2001165.

K. Mysore, G. Subbarayan, V. Gupta, and R. Zhang, Constitutive and aging behavior of Sn3.0Ag0.5Cu solder alloy. IEEE Trans. Electron. Packag. Manuf. 32, 221–232 (2009). https://doi.org/10.1109/TEPM.2009.2024119.

L. Shen, P. Lu, S. Wang, and Z. Chen, Creep behaviour of eutectic SnBi alloy and its constituent phases using nanoindentation technique. J. Alloys Compd. 574, 98–103 (2013). https://doi.org/10.1016/j.jallcom.2013.04.057.

H.N. Fowler, A. Loaiza, D.F. Bahr, J.E. Blendell, and C.A. Handwerker, Sb additions in near-eutectic Sn-Bi solder decrease planar slip. J. Electron. Mater. (2023). https://doi.org/10.1007/S11664-023-10666-6.

J.F. Li, S.H. Mannan, M.P. Clode, D.C. Whalley, and D.A. Hutt, Interfacial reactions between molten Sn-Bi-X solders and Cu substrates for liquid solder interconnects. Acta Mater. 54, 2907–2922 (2006). https://doi.org/10.1016/J.ACTAMAT.2006.02.030.

Y. Fan, Y. Wu, T.F. Dale, S.A.P. Lakshminarayana, C.V. Greene, N.U. Badwe, R.F. Aspandiar, J.E. Blendell, G. Subbarayan, and C.A. Handwerker, Influence of pad surface finish on the microstructure evolution and intermetallic compound growth in homogeneous Sn-Bi and Sn-Bi-Ag solder interconnects. J. Electron. Mater. 50, 6615–6628 (2021). https://doi.org/10.1007/S11664-021-09256-1.

S. Brown. Fatigue resistant lead-free alloy for under hood applications. OnBoard Technol. 31–36 (2008).

Acknowledgments

This work was supported in part by the Semiconductor Research Corporation (SRC) and Scalable Asymmetric Lifecycle Engagement (SCALE) at Purdue.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fowler, H.N., Puttur Lakshminarayana, S.A., Lai, S.Y. et al. Effect of Sb and Ag Addition and Aging on the Microstructural Evolution, IMC Layer Growth, and Mechanical Properties of Near-Eutectic Sn-Bi Alloys. J. Electron. Mater. 53, 1284–1298 (2024). https://doi.org/10.1007/s11664-023-10866-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-023-10866-0