Abstract

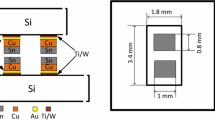

Special applications, such as microelectromechanical systems (MEMS), often require hermetic sealing in order to achieve a desired operation. Solid–liquid interdiffusion (SLID) bonding is an attractive method for encapsulating MEMS devices at the wafer-level, providing, e.g., high re-melt temperatures and tolerance for topographical variations. Several different SLID bond solutions have been investigated; however, there are only a limited number of published reliability studies available. In this paper, wafer-level Au-Sn and Cu-Sn SLID seal rings were mechanically characterized with shear and tensile tests. The evolution of bond microstructures and consequent effects on mechanical reliability were evaluated with a mixed flow gas test, a high temperature storage test and a thermal shock (TS) test. Virgin samples showed high mechanical strength. The Au-Sn system, with a thin Ni layer between the TiW adhesion layer and the bond, demonstrated a shear strength of 170 MPa. Cu-Sn, with a Cu-Cu3Sn-Cu structure, exhibited a shear strength of 275 MPa. Statistically significant decreases in strength were identified after reliability tests. The shear strength of the Au-Sn bond with an (AuSn + Au5Sn)eut structure decreased 40% in a corrosive environment. After 3000 TS cycles, the tensile strength of the Cu-Sn bond reduced by 45%. Fracture surface analysis revealed through-bond failures that were not observed previously. In cross-sectional analysis, vertical cracks were observed, which may contribute to the decrease in tensile strength.

Similar content being viewed by others

References

V. Chidambaram, J. Hattel, and J. Hald, Microelectron. Eng. 88, 981 (2011).

K. Suganuma, S. Kim, and K. Kim, JOM J Miner. Met. Mater. Soc. 61, 64 (2009).

G. Zeng, S. McDonald, and K. Nogita, Microelectron. Reliab. 52, 1306 (2012).

V. Lindroos, M. Tilli, A. Lehto, and T. Motooka, Handbook of Silicon Based MEMS Materials and Technologies (Amsterdam: Elsevier, 2010).

W. Welch III, J. Chae, S. Lee, N. Yazdi, and K. Najafi, Solid-State Sensors Actuators Microsystems Digital Technical Paper TRANSDUCERS’05, vol. 2 (2005).

W. Welch and K. Najafi, Solid-State Sensors Actuators Microsystems Conference TRANSDUCERS 2007 (2007).

W. Welch and K. Najafi, MEMS 2008. IEEE 21st International Conference (2008).

R.W. Johnson, C. Wang, Y. Liu, and J.D. Scofield, Electron. Packag. Manuf. IEEE Trans. 30, 182 (2007).

A. Yu, C.S. Premachandran, R. Nagarajan, C.W. Kyoung, L.Q. Trang, R. Kumar, L.S. Lim, J.H. Han, Y.G. Jie, and P. Damaruganath, Proceedings of the 60th Electronic Components and Technology Conference (ECTC) (2010).

M. Esashi, J. Micromech. Microeng. 18, 073001 (2008).

A. Garnier, E. Lagoutte, X. Baillin, C. Gillot, and N. Sillon, Proceedings of the 61st Electronic Components and Technology Conference (ECTC) IEEE (2011).

S. Marauska, M. Claus, T. Lisec, and B. Wagner, Microsyst. Technol. 19, 1119 (2013).

Y. Zhou, W. Gale, and T. North, Int. Mater. Rev. 40, 181 (1995).

L. Bernstein, J. Electrochem. Soc. 113, 1282 (1966).

J. Li, P. Agyakwa, and C. Johnson, Acta Mater. 58, 3429 (2010).

T.A. Tollefsen, A. Larsson, O.M. Løvvik, and K. Aasmundtveit, Metall. Mater. Trans. B 43, 397 (2012).

T.A. Tollefsen, A. Larsson, M.M.V. Taklo, A. Neels, X. Maeder, K. Høydalsvik, D.W. Breiby, and K. Aasmundtveit, Metall. Mater. Trans. B 44, 406 (2013).

T.A. Tollefsen, A. Larsson, O.M. Lovvik, and K.E. Aasmundtveit, Compon. Packag. Manuf. Tech. IEEE Trans. 3, 904 (2013).

T.A. Tollefsen, M.M.V. Taklo, K.E. Aasmundtveit, and A. Larsson, Proceedings of the 4th Electronic System-Integration Technology Conference ESTC, vol. 4 (2012), p. 1.

K. Wang, K. Aasmundtveit and H. Jakobsen, Proceedings of the 2nd Electronic System-Integration Technology Conference ESTC (2008), p. 1131.

A. Duan, K. Wang, K. E. Aasmundtveit, and N. Hoivik, Proceedings of the 4th Electronic System-Integration Technology Conference ESTC (2012), p. 1.

F. Bartels, J. Morris, G. Dalke, and W. Gust, J. Electron. Mater. 23, 787 (1994).

R. Agarwal, W. Zhang, P. Limaye, and W. Ruythooren, 59th Electronics Components & Technology Conference ECTC (2009), p. 345.

N. Bosco and F. Zok, Acta Mater. 53, 2019 (2005).

X. Wei, Y. Zhang, R. Wang, and Y. Feng, Microelectron. Reliab. 53, 748 (2013).

J. Yoon, H. Chun, and S. Jung, Mater. Sci. Eng. A 473, 119 (2008).

P. Hagler, R.W. Johnson, and L.-Y. Chen, IEEE Transactions on Components, Packaging and Manufacturing Technology, vol. 1 (2011), p. 630.

H. Xu, T. Suni, V. Vuorinen, J. Li, H. Heikkinen, P. Monnoyer, and M. Paulasto-Kröckel, Adv. Manuf. 1, 226 (2013).

T. Suni, H. Xu, V. Vuorinen, H. Heikkinen, S. Vahanen, A. Jaakkola, P. Monnoyer, and M. Paulasto-Krockel, Microelectronics Packaging Conference EMPC (2013), p. 1.

B. Balakrisnan, C.C. Chum, M. Li, Z. Chen, T. Cahyadi, and J. Electron, Mater. 32, 166 (2003).

J. De Winter, Pract. Assess. Res. Eval. 18, 1 (2013).

Y. Hu, Y. Zhao, and T. Yu, Microelectron. Reliab. 48, 1720 (2008).

ASTM B810-01a(2011), Standard Test Method for Calibration of Atmospheric Corrosion Test Chambers by Change in Mass of Copper Coupons (Philadelphia: ASTM, 2011).

GR-63-CORE, GR-63-CORE, Chapter 5.5, “Airborne contaminants test methods”, Telcordia Technologies (2002).

W.-H. Chen, H.-C. Cheng, and C.-F. Yu, International Conference on Thermal, Mechanical and Multiphysics Simulation and Experiments in Microelectronics and Microsystems, EuroSimE (2010), p. 1.

M.A. Hopcroft, W.D. Nix, and T.W. Kenny, Microelectromech. Syst. J. 19, 229 (2010).

T. Laurila, V. Vuorinen, and J. Kivilahti, Mater. Sci. Eng. R Rep. 49, 1 (2005).

H.Q. Dong, V. Vuorinen, T. Laurila, and M. Paulasto-Kröckel, CALPHAD 43, 61 (2013).

J. Yoon, H. Chun, and S. Jung, J. Mater. Res. 22, 1219 (2007).

T. Luu, A. Duan, K. Aasmundveit, and N. Hoivik, J. Electron. Mater. 12, 3582 (2013).

I. Panchenko, J. Grafe, M. Mueller, and K. Wolter, Proceedings of the 4rd Electronics System Integration Technology Conference ESTC (2012), p. 1.

R. Agarwal, W. Zhang, P. Limaye, and W. Ruythooren, 59th Electronic Components and Technology Conference (ECTC) (2009), p. 345.

W. Kim, Q. Wang, K. Jung, J. Hwang, and C. Moon, Proceedings of the 9th International symposium on Advanced Packaging Materials: Processes, Properties and. Interfaces (2004), p. 215.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rautiainen, A., Xu, H., Österlund, E. et al. Microstructural Characterization and Mechanical Performance of Wafer-Level SLID Bonded Au-Sn and Cu-Sn Seal Rings for MEMS Encapsulation. J. Electron. Mater. 44, 4533–4548 (2015). https://doi.org/10.1007/s11664-015-3929-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-015-3929-8