Abstract

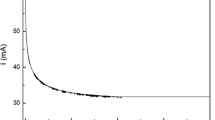

Oxygen potential of TiO2-FeO-Ti2O3 ternary slags was determined by the electromotive force (EMF) method based on the solid electrolyte oxygen sensor at 2003 K (1730 °C). The effect of FeO content and Ti3+/Ti4+ mass ratio on the oxygen potential of the high-titania slag was also studied. At a fixed Ti3+/Ti4+ mass ratio of 3.11, the oxygen potential increased with increasing FeO content. Increase of Ti3+/Ti4+ mass ratio from 2.29 to 3.60 caused a significant decrease in the oxygen potential of the slag. Comparing measured oxygen potential with the calculated values indicated that the oxygen potential of the slag might be determined by FeO/Fe equilibrium reaction rather than TiO2/Ti2O3 reaction. In addition, the experimentally measured oxygen potential values were modeled by multiple linear regression analysis, and a semi-empirical mathematical correlation was established between the oxygen potential and slag compositions. The iso-oxygen potential distribution diagram based on the mathematical model was obtained for the high-titania slag.

Similar content being viewed by others

References

H. G. Du and Z. P. Zhang, Iron Steel Vanadium Titanium, 1995, vol. 16, pp. 1-5.

K. Kiukkola and C. Wagner, Journal of the electrochemical society, 1957, vol. 104, pp. 308-316.

B. Coletti, S. Smets, B. Blanpain, P. Wollants, J. Plessers, C. Vercruyssen and B. Gommers, Ironmaking & Steelmaking, 2003, vol. 30, pp. 217-222.

M. Kawakami, K. S. Goto and M. Matsuoka, Metallurgical and Materials Transactions B, 1980, vol. 11, pp. 463-469.

J. W. Matousek, Jom, 2013, vol. 65, pp. 1584-1588.

K. Nagat and K. S. Goto, Solid State Ionics, 2006, vol. 9, pp. 1249-1256.

K. Nagata and K. S. Goto, Tetsu- to- Hagane, 2009, vol. 74, pp. 1801-1808.

E. T. Turkdogan, Ironmaking & Steelmaking, 2013, vol. 27, pp. 32-36.

O. Volkova, M. E. Vogel and D. Janke, Ironmaking & Steelmaking, 2003, vol. 30, pp. 287-292.

K. Q. Huang, Q. G. Liu, Iron & Steel, 1991, vol. 26, pp. 68-72.

P. Geldenhuis, P. C. Pistorius. Journal of the Southern African Institute of Mining and Metallurgy, 1999, vol. 99, pp. 41-47.

J. Pesl and R. Hurman Eriç, Metallurgical and Materials Transactions B, 1999, vol. 30, pp. 695-705.

K. Borowiec and T. Rosenqvist, Scandinavian Journal of Metallurgy, 1981, vol. 10, pp. 217-224.

S. K. Gupta, V. Rajakumar and P. Grieveson, Canadian Metallurgical Quarterly, 2013, vol. 28, pp. 331-335.

R. R. Merritt and A. G. Turnbull, Journal of Solid State Chemistry, 1974, vol. 10, pp. 252-259.

S. Itoh, O. Inoue and T. Azakami, Materials Transactions, JIM, 1998, vol. 39, pp. 391-398.

L. A. Taylor, R. J. Williams and R. H. McCallister, Earth and Planetary Science Letters, 1972, vol. 16, pp. 282-288.

H. Schmalzried, Berichte der Bunsengesellschaft für physikalische Chemie, 1962, vol. 66, pp. 572-576.

S. H. Liu, R. J. Fruehan, A. Morales and B. Ozturk, Metallurgical & Materials Transactions B, 2001, vol. 32, pp. 31-36.

K. Hu, X. W. Lv, S. P. Li, W. Lv, B. Song and K. Han, Metallurgical and Materials Transactions B, 2018, vol. 49, pp. 1963-1973.

From Stian Seim: NTNU, PhD Thesis, 2011, pp. 271.

G. Eriksson, A. D. Pelton, E. Woermann and A. Ender, Cheminform, 1997, vol. 100, pp. 1839-1849.

A. H. Webster and N. F. H. Bright, Journal of the American Ceramic Society, 2010, vol. 44, pp. 110-116.

G. Tranell, O. Ostrovski and S. Jahanshahi, Metallurgical and Materials Transactions B, 2002, vol. 33, pp. 61-67.

Acknowledgments

The authors are grateful to National Key R&D Program of China (2018YFC1900500). The chemical composition analysis of all the samples was performed by Panzhihua Iron and Steel Research Institute. The corresponding author prof. Xuewei Lv is especially grateful to prof. P. Christiaan Pistorius in Carnegie Mellon University for his constructive suggestions to this paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted October 9, 2018.

Rights and permissions

About this article

Cite this article

Hu, K., Lv, X., Yan, Z. et al. Oxygen Potential of High-Titania Slag from the Smelting Process of Ilmenite. Metall Mater Trans B 50, 1841–1851 (2019). https://doi.org/10.1007/s11663-019-01585-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-019-01585-1