Abstract

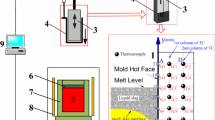

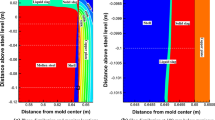

To determine the composition difference between the solid and liquid films in plant practice for high-Mn steel castings, a reaction experiment was carried out to investigate the composition profile of MnO and SiO2 in the slag layer. Based on the experimental results, a mathematical model of the mold slag for high-Mn steel was developed to describe the nonuniform infiltration behavior of mold slag during oscillation cycles. Moreover, the effects of uneven slag films on slab lubrication and heat transfer in the mold are discussed. The results show that the concentrations of MnO and SiO2 over the flux layer have an opposite stair-step distribution, which consists of a reaction layer and nonreaction layer. When the reaction layer thickness is 5 mm, a thicker liquid film is formed between the slab and the mold. The inhomogeneity of the composition in the solid film causes large fluctuations in the heat flux in the mold, resulting in irregular depressions on the shell surface. With a reacting thickness of 10 mm, the reacting slag fills in the gap to generate a thinner solid film, which increases the overall heat flux in the mold. Since mold oscillation combined with slag rim enhances the pressure flow in the vicinity of the meniscus, the liquid slag within 80 mm of the mold wall is mixed and consumed quickly. In contrast, the liquid slag beyond 80 mm from the mold wall with a low velocity stays longer in the liquid pool. The model predictions illuminate the characteristics of slag infiltration during high-Mn steel casting, showing good agreement with plant measurements.

Similar content being viewed by others

References

D. J. Kim and J. H. Park: Metall. Mater. Trans. B, 2012, vol. 43B, pp. 875-86.

M. S. Kim, S. W. Lee, J. W. Cho, M. S. Park, H. G. Lee, and Y. B. Kang: Metall. Mater. Trans. B, 2013, vol. 44B, pp. 299-308.

J. Yang and M. Zhu: ISIJ Int., 2016, vol. 56, pp. 2191-98.

K. Blazek, H. Yin, G. Skoczylas, M. McClymonds, and M. Frazee: Iron Steel Tech., 2011, vol. 8, pp. 231-40.

J. W. Cho, K. Blazek, M. Frazee, H. B. Yin, J. H. Park, and S. W. Moon: ISIJ Int., 2013, vol. 53, pp. 62-70.

D. **ao, W. L. Wang and B. X. Lu: Metall. Mater. Trans. B, 2015, vol. 46B, pp. 873-81.

C. B. Shi, M. D. Seo, J. W. Cho and S. H. Kim: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 1081-97.

X. J. Fu, G. H. Wen, P. Tang, Q. Liu and Z. Y. Zhou: Ironmak. Steelmak., 2014, vol. 41, pp. 342-49.

W. Yan, W. Q. Chen, Y. D. Yang, C. Lippold and A. Mclean: ISIJ Int., 2015, vol. 55, pp. 1000-09.

K. C. Mills, A. B. Fox, Z. Li and R. P. Thackray: Ironmak. Steelmak., 2005, vol. 32, pp. 26-34.

Sridhar S, Mills KC, Afrange ODC, LÖrz HP, Carli R (2000) Ironmak. Steelmak. 27:238–42.

H. J. Shin, S. H. Kim, B. G. Thomas, G. G. Lee, J. M. Park and J. Sengupta: ISIJ Int., 2006, vol. 46, pp. 1635-44.

R. Saraswat, A. B. Fox, K. C. Mills, P. D. Lee and B. Deo: Scand. J. Metall., 2004, vol. 33, pp. 85-91.

P. E. Ramirez-Lopez, P. D. Lee, K. C. Mills and B. Santilana: ISIJ Int., 2010, vol. 50, pp. 1797-1804.

T. Kajitani, K. Okazawa, W. Yamada and H. Yamamura: ISIJ Int., 2006, vol. 46, pp. 1432-41.

A. Jonayat and B. G. Thomas: Metall. Meter. Trans. B, 2014, vol. 45B, pp. 1842-64.

J. Yang, X. Meng, N. Wang and M. Zhu: Metall. Meter. Trans. B, 2017, vol. 48B, pp. 1230-47.

P. D. Lee, P. E. Ramirez-Lopez, K. C. Mills and B. Santillana: Ironmak. Steelmak., 2012, vol. 39, pp. 244-53.

J. Konishi, M. Militzer, J. K. Brimacombe and I. V. Samarasekera: Metall. Meter. Trans. B, 2002, vol. 33B, pp. 413-23.

K. C. Mills and A. B. Fox: ISIJ Int., 2003, vol. 43, pp. 1479-86.

Y. Meng and B. G. Thomas: Metall. Meter. Trans. B, 2003, vol. 34B, pp. 707-25.

M. Hanao and M. Kawamoto: ISIJ Int., 2008, vol. 48, pp. 180-85.

A. Badri, T. T. Natarajan, C. C. Snyder, K. D. Powers, F. J. Mannion, M. Byrne and A. W. Cramb: Metall. Meter. Trans. B, 2005, vol. 36B, pp. 373-83.

Y. Meng and B. G. Thomas: ISIJ Int., 2006, vol. 46, pp. 660-69.

J. Cho and H. Jeong: Metall. Meter. Trans. B, 2013, vol. 44B, pp. 146-53.

P. E. Ramirez-Lopez, P. D. Lee and K. C. Mills: ISIJ Int., 2010, vol. 50, pp. 425-34.

J. Yang, Z. Cai and M. Zhu: ISIJ Int., 2018, vol. 58, pp. 299-308.

X. Huang, B. G. Thomas and F. M. Najjar: Metall. Meter. Trans. B, 1992, vol. 23B, pp. 339-56.

Y. Meng and B. G. Thomas: Metall. Meter. Trans. B, 2003, vol. 34B, pp. 685-705.

A. C. Mikrovas, S. A. Argyropoulos and I. D. Sommerville: Iron Steelmaker, 1991, vol.18, pp. 51-61.

R. Eriksson and S. Seetharaman: Metall. Meter. Trans. B, 2004, vol. 35B, pp. 461-69.

K. C. Mills: Southern African Pyrometallurgy 2011 Int. Conf., 2011, pp. 1-52.

D. Ye and J. Hu: Handbook of Thermodynamic Data for Inorganic Materials, Metallurgical Industry Press, Bei**g, 2002.

Acknowledgments

The authors are especially grateful to the National Natural Science Foundation of China (Grant Numbers U1660204 and 51874060).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Manuscript submitted September 28, 2018.

Rights and permissions

About this article

Cite this article

Yang, J., Cai, Z., Chen, D. et al. Characteristics of Slag Infiltration in High-Mn Steel Castings. Metall Mater Trans B 50, 1104–1113 (2019). https://doi.org/10.1007/s11663-019-01511-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-019-01511-5