Abstract

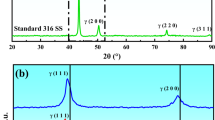

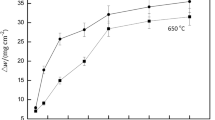

The time-dependent experiment was performed to investigate the corrosion behavior of low-temperature liquid nitrocarburized (LNC) 304 austenitic stainless steel in wet H2S environments. Characteristics of H2S corrosion products, as well as localized corrosion behavior, were investigated using X-ray diffraction (XRD), scanning electron microscopy, X-ray photoelectron spectroscopy (XPS), and optical profilometry. The results revealed that the untreated steels, of which the H2S corrosion product layer on the untreated surface thickened but displayed a layered defect structure as the corrosion proceeded, had a higher weight loss than the LNC. Energy-dispersive spectroscopy (EDS) served to reveal the relationship between corrosion behavior and the content of sulfur, chromium, and other elements, and the valences of these elements were illustrated by XPS. The surface morphology after removing corrosion products showed that the presence of nitrocarburized S phase could prevent general corrosion and inhibit pit propagation.

Similar content being viewed by others

References

Z. Wang, L. Zhang, X. Tang, Z. Zhang, and M. Lu: Appl. Surf. Sci., 2017, vol. 423, pp. 457–64.

J. Ding, L. Zhang, M. Lu, J. Wang, Z. Wen, and W. Hao: Appl. Surf. Sci., 2014, vol. 289, pp. 33–41.

P. Wang, J. Wang, S. Zheng, Y. Qi, M. **ong, and Y. Zheng: Int. J. Hydr. Energy, 2015, vol. 40, pp. 11925–11930.

L. Zeng, X.P. Guo, and G.A. Zhang: J. Alloy Compd., 2017, vol. 724, pp. 827–40.

E. Heitz: Electrochim. Acta, 1996, vol. 41, pp. 503–09.

X. Hu and A. Neville: Wear, 2009, vol. 267, pp. 2027–32.

J. Aguirre, M. Walczak, and M. Rohwerder: Wear, 2019, vols. 438–439, 203053.

X. Zhang, J. Wang, H. Fan, J. Yan, L. Duan, and T. Gu: Metall. Mater. Trans. A, 2018, vol. 49A, pp. 1–12.

E. Araújo, R. Bandeira, M. Manfrinato, J. Moreto, R. Borges, S. Vales, P. Suzuki, and L. Rossino: J. Mater. Res. Technol., 2019, vol. 8, pp. 2180–91.

J. Wang, Z. Li, D. Wang, S. Qiu, and F. Ernst: Acta Mater., 2017, vol. 128, pp. 235–40.

D. Wu, H. Kahn, J.C. Dalton, G.M. Michal, F. Ernst, and A.H. Heuer: Acta Mater., 2014, vol. 79, pp. 339–50.

Y. Sun and T. Bell: Tribol. Lett., 2002, vol. 13, pp. 29–34.

Y. Peng, C. Chen, X. Li, J. Gong, Y. Jiang, and Z. Liu: Surf. Coat. Technol., 2017, vol. 328, pp. 420–27.

X. Li, W. Dou, L. Tian, and H. Dong: Lubricants, 2018. doi:10.3390/lubricants6040093

G. Pintaude, A. Rovani, J. Das, L. Lagoeiro, X. Li, and H. Dong: J. Mater. Eng. Perform., 2019, vol. 28, pp. 3673–82.

X. Zhang, J. Wang, H. Fan, and D. Pan: Appl. Surf. Sci., 2018, vol. 440, pp. 755–62.

P. Wang, Z. Lv, S. Zheng, Y. Qi, J. Wang, and Y. Zheng: Int. J. Hydr. Energy, 2015, vol. 40, pp. 11514–11521.

W. Li, X. Zhu, C. Wang, and X. **: Mater. Today, 2015, vol. 2, pp. S691–S695.

X. Xu, L. Wang, Z. Yu, J. Qiang, and Z. Hei: Metall. Mater. Trans. A, 2000, vol. 31A, pp. 1193–99.

J. Wang, Y. Lin, and Q. Zhang: Metall. Mater. Trans. A, 2014, vol. 45A, pp. 4525–34.

M. Zhao, Y. Shan, R. Fu, Y. Ke, and H. Yu: Mater. Lett., 2002, vol. 57, pp. 141–45.

J. Wang, Y. Lin, M. Li, H. Fan, D. Zeng, and J. **ong: Metall. Mater. Trans. B, 2013, vol. 44B, pp. 1010–16.

R. Huang, J. Wang, S. Zhong, M. Li, J. **ong, and H. Fan: Appl. Surf. Sci., 2013, vol. 271, pp. 93–97.

G. Chen, J. Wang, H. Fan, D. Wang, X. Li, and H. Dong: J. Alloy Compd., 2019, vol. 776, pp. 702–11.

L. Li, J. Wang, J. Yan, L. Duan, X. Li, and H. Dong: Metall. Mater. Trans. A, 2018, vol. 49A, pp. 6521–32.

J. Wang, Y. Lin, J. Yan, D. Zen, Q. Zhang, and R. Huang: Surf. Coat. Technol., 2012, vol. 206, pp. 3399–3404.

K. Deng, Y. Lin, H. Ning, W. Liu, A. Singh, and G. Zhang: Appl. Geochem., 2018, vol. 99, pp. 22–30.

A. Groysman: Corrosion Problems and Solutions in Oil Refining and Petrochemical Industry, 1st ed., Springer International Publishing AG, Cham, Switzerland, 2017.

Standard Practice for Preparing, Cleaning, and Evaluating Corrosion Test Specimens, ASTM, West Conshohocken, PA, 2003.

P. Tewari, M. Bailey, and A. Campbell: Corros. Sci., 1979, vol. 19, pp. 573–85.

M. Alizadeh and S. Bordbar: Corros. Sci., 2013, vol. 70, pp. 170–09.

D. Rickard and G. Luther: ChemInform, 2007, vol. 38, pp. 514–62.

J. Sardisco, W. Wright, and E. Greco: Corrosion, 1963, vol. 19, pp. 354–59.

P. Tewari and A. Campbell: Can. J. Chem., 1979, vol. 57, pp. 188–96.

H. Dong: Int. Mater. Rev., 2010, vol. 55, pp. 65–98.

W. Hao, L. Zhang, and H. Li: Paper No. 11293, NACE International, Houston, TX, 2011.

L. Zhang, H. Li, and F. Shi: Int. J. Min. Met. Mater., 2017, vol. 24, pp. 401–09.

P. Bai, S. Zheng, and C. Chen: Mater. Chem. Phys., 2015, vols. 149–150, pp. 295–301.

Z. Wang, L. Zhang, Z. Zhang, and M. Lu: Appl. Surf. Sci., 2018, vol. 458, pp. 686–99.

D. Macdonald, S. Biaggio, and H. Song: J. Electrochem. Soc., 1992, vol. 139, pp. 170–76.

X. Liu, P. Okafor, and Y. Zheng: Corros. Sci., 2009, vol. 51, pp. 744–51.

Z. Iofa and V. Batrakov: Electrochim. Acta, 1964, vol. 9, pp. 1645–53.

R. King, J. Miller, and J. Smith: Br. Corros. J., 1973, vol. 8, pp. 137–41.

W. Fredriksson, S. Malmgren, T. Gustafsson, M. Gorgoi, and K. Edstr: Appl. Surf. Sci., 2012, vol. 258, pp. 5790–97.

A. Laszczyńska, W. Tylus, J. Winiarski, and I. Szczygieł: Surf. Coat. Technol., 2017, vol. 317, pp. 26–37.

G. Myburg, K. Varga, W.O. Barnard, P. Baradlai, L. Tomcsányi, J.H. Potgieter, C.W. Louw, and M.J. van Staden: Appl. Surf. Sci., 1998, vol. 136, pp. 29–35.

L. Zeng, X.P. Guo, G.A. Zhang, and H.X. Chen: Corros. Sci., 2018, vol. 144, pp. 258–65.

J.E. Castle: J. Electrochem. Soc., 1990, vol. 137, p. 2031.

H.W. Nesbitt, D. Legrand, and G.M. Bancroft: Phys. Chem. Miner., 2000, vol. 27, pp. 357–66.

H. Feng, Z. Jiang, H. Li, P. Lu, S. Zhang, H. Zhu, B. Zhang, T. Zhang, D. Xu, and Z. Chen: Corros. Sci., 2018, vol. 144, pp. 288–300.

S. Ningshen, U. KamachiMudali, V.K. Mittal, and H.S. Khatak: Corros. Sci., 2007, vol. 49, pp. 481–96.

M. Monnot, R.P. Nogueira, V. Roche, G. Berthomé, E. Chauveau, R. Estevez, and M. Mantel: Appl. Surf. Sci., 2017, vol. 394, pp. 132–41.

M.B. Kermani and A. Morshed: Corrosion, 2003, vol. 59, pp. 659–83.

G. Schmidt: Advance in CO2 Corrosion, vol. 1, NACE, Houston, TX, 1984, pp. 1–2.

A. Jarrah, M. Bigerelle, G. Guillemot, D. Najjar, A. Iost, and J.-M. Nianga: Corros. Sci., 2011, vol. 53, pp. 2453–67.

L. Organ, J.R. Scully, A.S. Mikhailov, and J.L. Hudson: Electrochim. Acta, 2005, vol. 51, pp. 225–41.

P. Marcus, V. Maurice, and H. Strehblow: Corros. Sci., 2008, vol. 50, pp. 2698–2704.

J. Soltis: Corros. Sci., 2015, vol. 90, pp. 5–22.

P. Bai, H. Zhao, S. Zheng, and C. Chen: Corros. Sci., 2015, vol. 93, pp. 109–19.

R. Wei, X. Chen, Z. Ai, and Y. **: Int. J. Hydrogen Energy, 2018, vol. 43, pp. 9059–67.

Acknowledgments

The authors are grateful for the grants provided by the National Natural Science Foundation of China (Grant Nos. 51471112 and 51611130204), the Science and Technology Planning Project of Sichuan (Grant No. 2016GZ0173), and the Royal Society, United Kingdom (Newton Mobility Grant No. IE151027).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted December 13, 2019.

Rights and permissions

About this article

Cite this article

Li, L., Wang, J., Tang, Z. et al. Low-Temperature Nitrocarburizing of Austenitic Stainless Steel for Combat Corrosion in H2S Environments. Metall Mater Trans A 51, 4242–4256 (2020). https://doi.org/10.1007/s11661-020-05802-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05802-4