Abstract

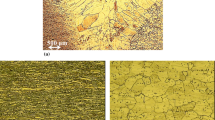

The present study makes an attempt to understand the influence of welding speed on the formability of a welded microalloyed steel. An optimum heat input for laser welding was maintained in this study, under bead-on-plate and butt-welding conditions, with varying welding speed. Initially, the heat-affected zone (HAZ) had a moderate γ-fiber texture, which was later distorted with the increased speed of welding. There was an enhancement of rotated cube {001}〈110〉 and cube {001}〈010〉 orientations. The fusion zone (FZ) exhibited mainly random texture, without any presence of γ-fiber. However, faster speeds resulted in strengthening of intensities close to the rotated cube {001}〈110〉 and cube {001}〈010〉 orientations in the FZ. The increased welding speed resulted in enlargement of dimples of fracture surface for the HAZ, finally leading to a transition into a mixed mode of fracture. With increased welding speed, the FZ exhibited a drop in the equiaxiality of the austenite grains. The enhancement of the columnar nature of the austenite grains at the FZ could be correlated with the cube texture formation and deterioration in formability of the welded material.

Similar content being viewed by others

References

H.J. Bunge: Texture Analysis in Materials Science, Butterworths, London, 1982.

H.J. Bunge: Int. Mater. Rev., 1987, vol. 32 (1), pp. 265–91.

H. Inagaki, K. Kurihara, and I. Kozasu: Trans. Iron Steel Inst. Jpn., 1977, vol. 17 (2), pp. 75–81.

R.K. Ray and J.J. Jonas: Int. Mater. Rev., 1990, vol. 35 (1), pp. 1–36.

A. Riemer, S. Leuders, M. Thöne, H.A. Richard, T. Tröster, and T. Niendorf: Eng. Fract. Mech., 2014, vol. 120, pp. 15–25.

J. Suryawanshi, K.G. Prashanth, and U. Ramamurty: Mater. Sci. Eng. A, 2017, vol. 696, pp. 113–21.

T. DebRoy, H.L. Wei, J.S. Zuback, T. Mukherjee, J.W. Elmer, J.O. Milewski, A.M. Beese, A. Wilson-Heid, A. De, and W. Zhang: Progr. Mater. Sci., 2018, vol. 92, pp. 112–224.

R.K. Ray, J.J. Jonas, and R.E. Hook: Int. Mater. Rev., 1994, vol. 39 (4), pp. 129–72.

X.J. Shen, S. Tang, Y.J. Wu, X.L. Yang, J. Chen, Z.Y. Liu, R.D.K. Misra, and G.D. Wang: Mater. Sci. Eng.: A, 2017, vol. 685, pp. 194–204.

I. Lischewski and G. Gottstein: Acta Mater., 2011, vol. 59 (4), pp. 1530–41.

R. Joodaki, S.R. AlaviZaree, K. Gheisari, and M. Eskandari: J. Mater. Eng. Perform., 2017, vol. 26, pp. 2003–13.

Q. Chu, R. Baib, H. Jian, Z. Lei, N. Hu, and C. Yan: Mater. Charact., 2018, vol. 137, pp. 269–76.

H. Gao, G. Agarwal, M. Amirthalingam, M.J.M. Hermans, and I.M. Richardson: Weld. World, 2018, vol. 62, pp. 71–78.

T. Soysal and S. Kou: Acta Mater., 2018, vol. 143, pp. 181–97.

S. Suwas and R.K. Ray: Crystallographic Texture of Materials, Springer, London, 2014.

S. Keeler, M. Kimchi, and P.J. Mconey: Advanced High-Strength Steels Application Guidelines, Technical Report 6.0, World Auto Steel, Brussels, 2017.

Z. Yang and A. Bandivadekar: “Light-Duty Vehicle Greenhouse Gas and Fuel Economy Standards,” Technical Report, The International Council on Clean Transportation, Washington, DC, 2017.

C. Lesch, N. Kwiaton, and F.B. Klose: Steel Res. Int., 2017, vol. 88 (10), pp. 1–21.

S. Katayama: Handbook of Laser Welding Technologies, Woodhead Publishing Series in Electronic and Optical Materials, Elsevier, Amsterdam, 2013.

M.S. Wȩglowski, S. Błacha, and A. Phillips: Vacuum, 2016, vol. 130, pp. 72–92.

K.M. Hong and Y.C. Shin: J. Mater. Process. Technol., 2017, vol. 245, pp. 46–69.

W. Chen, P. Ackerson, and P. Molian: Mater. Des., 2009, vol. 30 (2), pp. 245–51.

A.K. Sinha, D.Y. Kim, and D. Ceglarek: Opt. Las. Eng., 2013, vol. 51 (10), pp. 1143–52.

Q. Sun, H. Di, J. Li, B. Wu, and R.D.K. Misra: Mater. Sci. Eng.: A, 2016, vol. 669, pp. 150–58.

M. Moradi, M. Ghoreishi, and A. Khorram: Las. Eng., 2018, vol. 39 (3–6), pp. 379–91

M. Nouroozi, H. Mirzadeh, and M. Zamani: Mater. Sci. Eng.: A, 2018, vol. 736, pp. 22–26.

A. Das and S. Tarafder: Int. J. Plasticity, 2009, vol. 25, pp. 2222–47.

C. **e, S. Yang, H. Liu, Q. Zhang, Y. Cao, and Y. Wang: J. Mater. Eng. Perform., 2017, vol. 26 (8), pp. 3794–3801.

G. Agarwal, M. Amirthalingam, S.C. Moon, R.J. Dippenaar, I.M. Richardson, and M.J.M. Hermans: Scripta Mater., 2018, vol. 146, pp. 105–09.

L. **e, P. Yang, N. Zhang, C. Zong, D. **a, and W. Mao: J. Magn. Magn. Mater., 2014, vol. 356, pp. 1–4.

J. Li, C. Yuan, Q. Qi, X. Bao, and X. Gao: Metals, 2017, vol. 7, p. 36.

Acknowledgments

The authors express their gratitude to Tata Steel R&D management for providing all the necessary support for this project work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted October 4, 2019.

Rights and permissions

About this article

Cite this article

Mitra, S., Arora, K.S., Bhattacharya, B. et al. Effect of Welding Speed on Texture in Laser-Welded Dual-Phase Steel. Metall Mater Trans A 51, 2915–2926 (2020). https://doi.org/10.1007/s11661-020-05747-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05747-8