Abstract

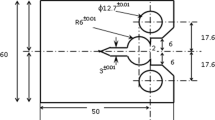

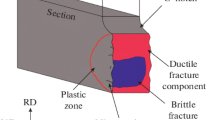

The J-integral fracture toughness values of high-Mn steel (Fe-25 wt pct Mn) and 304L stainless steel were evaluated at 25 °C, 0 °C, − 50 °C, − 100 °C, − 163 °C, and − 196 °C using precracked compact tension (CT) specimens and compared to those determined using Charpy impact tests. The high-Mn steel exhibited excellent J-integral fracture toughness at both room and cryogenic temperatures, with values comparable to those of 304L stainless steel. However, the trend of the J-integral fracture toughness of high-Mn steel with the decreasing temperature differed from that of the Charpy impact test results. Electron backscattered diffraction and micrographic analyses suggest that the varying stacking fault energies of high-Mn steels at different temperatures affected the deformation behavior in the stretch zone at the crack tip of the CT specimen. The effect of this temperature-dependent deformation behavior of high-Mn steels on the fracture process in the J-integral test could differ from that in the Charpy impact test, resulting in the different trends in the fracture resistance with the decreasing temperature.

Similar content being viewed by others

References

1. X.J. Wang, X.J. Sun, C. Song, H. Chen, W. Han, and F. Pan: Mater. Sci. Eng. A, 2017, vol. 698, pp. 110-16.

2. J.-S. Kim, J.B. Jeon, J.E. Jung, K.-K. Um, and Y.W. Chang: Met. Mater. Int., 2014, vol. 20, pp. 41-47.

3. J. Kim, S.-J. Lee, and B.C. De Cooman: Scr. Mater., 2011, vol. 65, pp. 363-66.

4. L. Mosecker, D. Pierce, A. Schwedt, M. Beighmohamadi, J. Mayer, W. Bleck, and J. Wittig: Mater. Sci. Eng. A, 2015, vol. 642, pp. 71-83.

5. K. Han, J. Yoo, B. Lee, I. Han, and C. Lee: Mater. Sci. Eng. A, 2014, vol. 618, pp. 295-304.

B. Bhattacharya T.K. Roy, C. Ghosh, and S.K. Ajmani, eds.: in Lecture Notes in Mechanical Engineering, Springer, Singapore, 2018, p. 46.

7. B.C. De Cooman, Y. Estrin, and S.K. Kim: Acta Mater., 2018, vol. 142, pp. 283-362.

8. G. Frommeyer, U. Brüx, and P. Neumann: ISIJ Int., 2003, vol. 43, pp. 438-46.

9. S. Allain, J.P. Chateau, and O. Bouaziz: Steel Res., 2002, vol. 73, pp. 299-302.

10. S. Curtze and V.-T. Kuokkala: Acta Mater., 2010, vol. 58, pp. 5129-41.

11. C. Zheng and W. Yu: Mater. Sci. Eng. A, 2018, vol. 710, pp. 359-65.

12. A. Dumay, J.-P. Chateau, S. Allain, S. Migot, and O. Bouaziz: Mater. Sci. Eng. A, 2008, vol. 483, pp. 184-87.

13. S.S. Sohn, S. Hong, J. Lee, B.-C. Suh, S.-K. Kim, B.-J. Lee, N.J. Kim, and S. Lee: Acta Mater., 2015, vol. 100, pp. 39-52.

14. W. Seo, D. Jeong, H. Sung, and S. Kim: Mater. Charact., 2017, vol. 124, pp. 65-72.

15. J.-E. ** and Y.-K. Lee: Acta Mater., 2012, vol. 60, pp. 1680-88.

16. A.S. Hamada, A. Kisko, A. Khosravifard, M.A. Hassan, L.P. Karjalainen, and D. Porter: Mater. Sci. Eng. A, 2018, vol. 712, pp. 255-65.

17. J. Kim, Y. Estrin, H. Beladi, I. Timokhina, K.-G. Chin, S.-K. Kim, and B.C. De Cooman: Metall. Mater. Trans. A, 2012, vol. 43, pp. 479-90.

18. R.A. Mesquita, R. Schneider, K. Steineder, L. Samek, and E. Arenholz: Metall. Mater. Trans. A, 2013, vol. 44, pp. 4015-19.

19. S. Martin, S. Wolf, U. Martin, L. Krüger, and D. Rafaja: Metall. Mater. Trans. A, 2016, vol. 47, pp. 49-58.

20. H.K. Sung, S.S. Sohn, S.Y. Shin, K.S. Oh, and S. Lee: Metall. Mater. Trans. A, 2014, vol. 45, pp. 3036-50.

ASTM E8/E8M-16a: Standard Test Methods for Tension Testing of Metallic Materials, Annual book of ASTM standards, vol. 03.01, 2016.

ASTM E1820-17: Standard Test Method for Measurement of Fracture Toughness, Annual book of ASTM standards, vol. 03.01, 2017.

23. A. Saeed-Akbari, J. Imlau, U. Prahl, and W. Bleck: Metall. Mater. Trans. A, 2009, vol. 40, pp. 3076-90.

24. S. Allain, J.P. Chateau, O. Bouaziz, S. Migot, and N. Guelton: Mater. Sci. Eng. A, 2004, vol. 387-389, pp. 158-62.

Y.-K. Lee and C. Choi: Metall. Mater. Trans. A, 2000, vol. 31, pp. 355-60.

26. A. Das: Metall. Mater. Trans. A, 2015, vol. 47, pp. 748–68.

27. X.J. ** and T.Y. Hsu: Mater. Chem. Phys., 1999, vol. 61, pp. 135–38.

28. A.T. Dinsdale: Calphad, 1991, vol. 15, pp. 317–425.

29. W.S. Yang and C.M. Wan: J. Mater. Sci., 1990, vol. 25, pp. 1821–23.

30. L. Li and T.Y. Hsu: Calphad, 1997, vol. 21, pp. 443–48.

31. S. Asgari, E. El-Danaf, S.R. Kalidindi, and R.D. Doherty: Metall. Mater. Trans. A, 1997, vol. 28, pp. 1781-95.

32. L. Remy: Acta Mater., 1978, vol. 26, pp. 443-51.

33. Z. Chen, J. Pan, T. **, Z. Hong, and Y. Wu: Theor. Appl. Fract. Mech., 2018, vol. 96, pp. 443-51.

34. M. Valo, K. Wallin, K. Törrönen, and R. Ahlstrand: Int. J. Pressure Vessels Pip., 1993, vol. 55, pp. 81-88.

35. A. Nazari and A.A. Milani: Mater. Sci. Eng. A, 2011, vol. 528, pp. 3854-59.

36. F. Wetscher, R. Stock, and R. Pippan: Mater. Sci. Eng. A, 2007, vol. 445-446, pp. 237-43.

37. J.G. Cowie, M. Azrin, and G.B. Olson: Metall. Mater. Trans. A, 1989, vol. 20, pp. 143-53.

38. R.J. Klassen, G.C. Weatherly, and B. Ramaswami: Metall. Mater. Trans. A, 1992, vol. 23, pp. 3273-80.

39. C. Beachem and G. Yoder: Metall. Mater. Trans. B, 1973, vol. 4, pp. 1145-53.

40. A. Gajji and G. Sasikala: Eng. Fract. Mech., 2017, vol. 180, pp. 148-60.

ASTM E647-15: Standard Test Method for Measurement of Fatigue Crack Growth Rates, Annual book of ASTM standards, vol. 03.01, 2015.

42. I. Černý: Eng. Fract. Mech., 2004, vol. 71, pp. 837-48.

43. S. Cravero and C. Ruggieri: Eng. Fract. Mech., 2007, vol. 74, pp. 2735-57.

44. Z. Xu, H.J. Roven, and Z. Jia: Mater. Sci. Eng. A, 2017, vol. 679, pp. 379-90.

45. D. Geissler, J. Freudenberger, A. Kauffmann, S. Martin, and D. Rafaja: Philos. Mag., 2014, vol. 94, pp. 2967-79.

46. J. Smith, M.N. Bassim, and C.D. Liu: Eng. Fract. Mech., 1995, vol. 52, pp. 401-08.

47. S.K. Das, S. Sivaprasad, S. Das, S. Chatterjee, and S. Tarafder: Mater. Sci. Eng. A, 2006, vol. 431, pp. 68-79.

48. A. Halim, W. Dahl, and K. Hagedorn: Eng. Fract. Mech., 1988, vol. 31, pp. 857-66.

49. M.N. Bassim, J.R. Matthews, and C.V. Hyatt: Eng. Fract. Mech., 1992, vol. 43, pp. 297-303.

Acknowledgments

This work was supported by a National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (2017R1C1B5018001), and a NRF Grant funded by the Korea government (MSIP) (2018R1A5A6075959). This work was also supported by the Industrial Strategic Technology Development Program (No. 10062304) funded by the Ministry of Trade, Industry & Energy (MOTIE, Republic of Korea).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted July 21, 2018.

Rights and permissions

About this article

Cite this article

Park, J., Lee, K., Sung, H. et al. J-integral Fracture Toughness of High-Mn Steels at Room and Cryogenic Temperatures. Metall Mater Trans A 50, 2678–2689 (2019). https://doi.org/10.1007/s11661-019-05200-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05200-5