Abstract

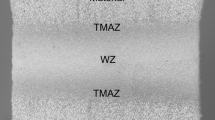

Residual strains in linear friction welds (LFW) of similar, Ti-6Al-4V (Ti64) welded to Ti-6Al-4V, and dissimilar, Ti-6Al-4V welded to Ti-5Al-5V-5Mo-3Cr (Ti5553), titanium alloys have been characterized using energy-dispersive X-ray diffraction. For each type of LFW, one sample was chosen in the as-welded (AW) condition and another sample was selected after a post-weld heat treatment (HT). In the present work, residual strains have been separately studied in the alpha and beta phases of the material, and five components (three axial and two shear) have been reported in each case. In-plane axial components of the residual strains show a smooth and symmetric behavior about the weld center for the Ti64-Ti64 LFW samples in the AW condition, whereas these components in the Ti64-Ti5553 LFW sample show a symmetric trend with jump discontinuities. Such jump discontinuities, observed in both the AW and HT conditions of the Ti64-Ti5553 samples, suggest different strain-free lattice parameters in the weld region and the parent material, whereas the results from the Ti64-Ti64 LFW samples in both AW and HT conditions suggest nearly uniform strain-free lattice parameters throughout the weld region. Finally, the observed trends in the in-plane axial residual strain components have been rationalized by the corresponding microstructural changes and variations across the weld region via backscatter electron (BSE) images.

Similar content being viewed by others

Notes

If the condition number of the coefficient matrix of a linear system is very large (≫ 1), it is practically singular. Hence, the solution of the linear system is prone to large numerical error.

It is to be noted, when \( \theta_{v} ,\theta_{h} \) or \( \chi \) are neglected, a few columns of \( {\varvec{A}} \) matrix only contain zeros. Those columns are neglected while calculating condition number.

References

J. Cho, K. Conlon, and R. Reed: Metall. Mater. Trans. A, 2003, vol. 34, pp. 2935–46.

I. Bhamji, M. Preuss, P.L. Threadgill, and A.C. Addison: Mater. Sci. Technol., 2011, vol. 27, pp. 2–12.

R. Turner, R.M. Ward, R. March, and R.C. Reed: Metall. Mater. Trans. B Process Metall. Mater. Process. Sci., 2012, vol. 43, pp. 186–97.

P.J. Withers: Reports Prog. Phys., 2007, vol. 70, pp. 2211–64.

P.J. Withers and H.K.D.H. Bhadeshia: Mater. Sci. Technol., 2001, vol. 17, pp. 355–65.

V. Hauk: Structural and Residual Stress Analysis by Nondestructive Methods, Elsevier, 1997.

I.A. Denks, M. Klaus, and C. Genzel: Mater. Sci. Forum, 2006, vol. 524–525, pp. 37–44.

C. Genzel, I.A. Denks, R. Coelho, D. Thomas, R. Mainz, D. Apel, and M. Klaus: J. Strain Anal. Eng. Des., 2011, vol. 46, pp. 615–25.

W. Reimers, M. Broda, G. Brusch, D. Dantz, K.D. Liss, A. Pyzalla, T. Schmackers, and T. Tschentscher: J. Non-Destructive Eval., 1998, vol. 17, pp. 129–40.

A. Steuwer, J.R. Santisteban, M. Turski, P.J. Withers, and T. Buslaps: J. Appl. Crystallogr., 2004, vol. 37, pp. 883–9.

M. Croft, I. Zakharchenko, Z. Zhong, Y. Gurlak, J. Hastings, J. Hu, R. Holtz, M. Dasilva, and T. Tsakalakos: J. Appl. Phys., 2002, vol. 92, pp. 578–86.

M.R. Daymond and N.W. Bonner: Phys. B Condens. Matter, 2003, vol. 325, pp. 130–37.

M. Preuss, J. Quinta Da Fonseca, A. Steuwer, L. Wang, P.J. Withers, and S. Bray: J. Neutron Res., 2004, vol. 12, pp. 165–73.

J. Romero, M.M. Attallah, M. Preuss, M. Karadge, and S.E. Bray: Acta Mater., 2009, vol. 57, pp. 5582–92.

P. Frankel, M. Preuss, A. Steuwer, P.J. Withers, and S. Bray: Mater. Sci. Technol., 2009, vol. 25, pp. 640–50.

P. **e, H. Zhao, and Y. Liu: Sci. Technol. Weld. Join., 2016, vol. 21, pp. 351–57.

SAE-AMS 4911H: SAE International, Warrendale, PA, USA, 1995, p. 1.

T. Ungár: Scr. Mater., 2004, vol. 51, pp. 777–81.

R. Young: Int. Union Crystallogr., 1993.

S.L.R. da Silva, L.O. Kerber, L. Amaral, and C.A. dos Santos: Surf. Coatings Technol., 1999, vol. 116–119, pp. 342–46.

M.B. Ivanov, S.S. Manokhin, Y.R. Kolobov, and D.A. Nechayenko: Mater. Phys. Mech., 2010, vol. 10, pp. 62–71.

A.K. Swarnakar, O. Van Der Biest, and B. Baufeld: J. Alloys Compd., 2011, vol. 509, pp. 2723–28.

L. Thijs, F. Verhaeghe, T. Craeghs, J. Van Humbeeck, and J.P. Kruth: Acta Mater., 2010, vol. 58, pp. 3303–12.

J.V. Bernier, J.-S. Park, A.L. Pilchak, M.G. Glavicic, and M.P. Miller: Metall. Mater. Trans. A, 2008, vol. 39, pp. 3120–33.

M. Kasemer, R. Quey, and P. Dawson: J. Mech. Phys. Solids, 2017, vol. 103, pp. 179–98.

T. Ozturk and A.D. Rollett: Comput. Mech., 2017, pp. 1–16.

K.M. Knowles and P.R. Howie: J. Elast., 2015, vol. 120, pp. 87–108.

D. Tromans: Int. J. Res. Rev. Appl. Sci., 2011, vol. 6, pp. 462–83.

Acknowledgments

Financial support for this work was provided by the National Science Foundation (Grant Number CMMI 16-51956) under program manager, Dr. Alexis Lewis, and the Lightweight Innovation for Tomorrow Institute (Grant Number LIFT TMP-3a). Base materials for the Ti64-Ti64 and Ti64-Ti5553 welds were provided by Dr. Tom Broderick (GE) and Dr. Austin Mann (Boeing), respectively. The authors thank Dr. Andrew Chuang (APS) for assistance with the setup of the EDD measurement. Use of the Advanced Photon Source was supported by the US Department of Energy, Office of Science, Office of Basic Energy Sciences, under Contract No. DE-AC02-06CH11357.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted June 6, 2018.

Rights and permissions

About this article

Cite this article

Bandyopadhyay, R., Rotella, J., Naragani, D. et al. Residual Strain Analysis in Linear Friction Welds of Similar and Dissimilar Titanium Alloys Using Energy Dispersive X-ray Diffraction. Metall Mater Trans A 50, 704–718 (2019). https://doi.org/10.1007/s11661-018-5034-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-5034-0