Abstract

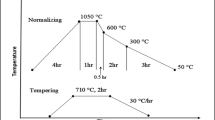

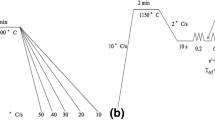

The effect of boron on the microstructures and mechanical properties of laboratory-control-rolled and direct-quenched 6-mm-thick steels containing 0.08 wt pct C and 0.02 wt pct Nb were studied. The boron contents were 24 ppm and a residual amount of 4 ppm. Two different finish rolling temperatures (FRTs) of 1093 K and 1193 K (820 °C and 920 °C) were used in the hot rolling trials to obtain different levels of pancaked austenite prior to DQ. Continuous cooling transformation (CCT) diagrams were constructed to reveal the effect of boron on the transformation behavior of these steels. Microstructural characterization was carried out using various microscopy techniques, such as light optical microscopy (LOM) and scanning electron microscopy-electron backscatter diffraction (SEM-EBSD). The resultant microstructures after hot rolling were mixtures of autotempered martensite and lower bainite (LB), having yield strengths in the range 918 to 1067 MPa with total elongations to fracture higher than 10 pct. The lower FRT of 1093 K (820 °C) produced better combinations of strength and toughness as a consequence of a higher degree of pancaking in the austenite. Removal of boron lowered the 34 J/cm2 Charpy-V impact toughness transition temperature from 206 K to 158 K (−67 °C to −115 °C) when the finishing rolling temperature of 1093 K (820 °C) was used without any loss in the strength values compared to the boron-bearing steel. This was due to the finer and more uniform grain structure in the boron-free steel. Contrary to expectations, the difference was not caused by the formation of borocarbide precipitates, as verified by transmission electron microscopy (TEM) investigations, but through the grain coarsening effect of boron.

Similar content being viewed by others

References

G.C. Hwang, S. Lee, J.Y. Yoo, and W.Y. Choo: Mater. Sci. Eng. A, 1998, vol. 252, pp. 256-68.

C. Ouchi: ISIJ Int., 2001, vol. 41, pp. 542-53.

H. Asahi, T. Hara, M. Sugiyama, N. Maruyama, Y. Terada, H. Tamehiro, K. Koyama, S. Ohkita, H. Morimoto, K. Tomioka, N. Doi, M. Murata, N. Ayukawa, H. Akasaki, D.P. Fairchild, M.L. Macia, C.W. Petersen, J.Y. Koo, N.V. Bangaru, and M.J. Luton: Int. J. Offshore Polar Eng., 2004, vol. 14, pp. 11-17.

A.J. Kaijalainen, P.P. Suikkanen, L.P. Karjalainen, J.I. Kömi, and A.J. DeArdo: Proc. 2nd Int. Conf. Super-High Strength Steels, Garda, Italy, 2010.

M. Hemmilä, R. Laitinen, T. Liimatainen, and D. Porter: 1st Int. Conf. on Super-High Strength Steels, Rome, 2005.

A.J. Kaijalainen, P.P. Suikkanen, L.P. Karjalainen, D.A. Porter, J.I. Kömi, and T.J. Limnell: J. Alloys Compd., 2013, 577, pp. 642-48.

M.C. Somani, D.A. Porter, J. Pyykkönen, J. Tarkka, J. Kömi, and L.P. Karjalainen: Proc. Int. Conf. Microalloyed Steels: Processing, Microstructure, Properties and Performance (MA’07), AIST, University of Pittsburgh, Pittsburgh, PA, 2007, pp. 95–106.

C. Klinkenberg: Mater. Sci. Forum, 2007, vols. 539–543, pp. 4261-66.

A.J. DeArdo: Fundamental Metallurgy of Niobium in Steel, Nb Science and Technology, TMS, Warrendale, PA, 2001, pp. 427-78.

C.R. Simcoe, A.R. Elaea, and G.K. Manning: Trans. TMS-AIME, 1956, vol. 206, pp. 984-88.

B.M. Kapadia, R.M. Brown, and W.J. Murphy: Trans. TMS-AIME, 1968, vol. 242, pp. 1689-94.

A. Brown, J.D Garnish, and R.W.K. Honeycombe: Mater. Sci. Technol., 1974, vol. 8, pp. 317-24.

M. Ueno and T. Inoue: Trans. Iron Steel Inst. Jpn., 1973, vol. 13, pp. 210-17.

P. Maitrepierre, J. Rofes-Vernis, and D. Thivellier: Boron in Steel, S.K. Banerji and J.E. Morral, eds., AIME, Warrendale, PA, 1979.

W. Yan, Y.Y. Shan, and K. Yang: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 2147-58.

A. Ghosh, S. Das, and S. Chatterjee: Mater. Sci. Technol., 2005, vol. 21, pp. 325-33.

J. Hannula: Master’s Thesis, University of Oulu, 2012 (in Finnish).

ISO 6892-1:2009 standard for tensile testing.

European Standard EN 10045-1:1990 E, Metallic Materials–Charpy Impact Test–Part 1: Test Method, March 1990.

W. Oldfield: Curve Fitting Impact Test Data: A Statistical Procedure, ASTM Standardization News, 1975, vol. 3, pp. 24-29.

M.J. EricksonKirk, M.T. EricksonKirk, S. Rosinski, and J. Spanner: J. Pressure Vessel Technol., 2009, vol. 131, pp. 1-12.

R.L. Higginson and C.M. Sellars: Worked Examples in Quantitative Metallography, Maney Publishing, London, 2003.

D. Chakrabarti, C.L. Davis, and M. Strangwood: Mater. Sci. Technol., 2009, vol. 25, pp. 939-46.

X.L. He, M. Djahazi, J.J. Jonas, and J. Jackman: Acta Metall. Mater., 1991, vol. 39, pp. 2295-308.

X.M. Wang and X.L. He: ISIJ Int., 2002, vol. 42, pp. 38-46.

L.J. Drewett, S. Bremer, M. Liebeherr, W. De Waele, A. Martin-Meizoso, J. Brózda, B. Zeislmair, H. Morbacher, D. Porter, and N. Gubeljak: “HIPERC: A Novel, High Performance, Economic Steel Concept for Linepipe and General Structural Use,” Research Fund for Coal and Steel Report, Contract No. RFSR-CT-2005-00027, EUR 24209 EN, 2010.

H. Tamehiro, M. Murata, R. Habu, and M. Nagumo: Trans. ISIJ, 1987, vol. 27, pp. 120-29.

F. Boratto, R. Barbosa, S. Yue, and J.J. Jonas: Proc. Int. Conf. on Physical Metallurgy of Thermomechanical Processing of Steels and Other Metals (THERMEC ’88), I. Tamura, ed., ISIJ, Tokyo, 1988, pp. 383–89.

Z. Aretxabaleta, B. Pereda, and B. Lopez: Mater. Sci. Eng. A, 2014, vol. 600, pp. 37-46.

P.P. Suikkanen: Ph.D. Thesis, University of Oulu, Oulu, 2009, accessed 17 May 2017.

X. Sun, Z. Li, Q. Yong, Z. Yang, H. Dong, and Y Weng: Sci. China Technol. Sci., 2012, vol. 55, pp. 1797-805.

S. Morito, H. Tanaka, R. Konishi, T. Furuhara, and T. Maki: Acta Mater., 2003, vol. 51, p. 1789-99.

S. Zajac, C. Schwinn, and K.H. Tacke: Mater. Sci. Forum, 2005, vols. 500–501, pp. 387-94.

L. Ryde: Mater. Sci. Technol., 2006, vol. 22, pp. 1297-306.

T. Hara, H Asahi, R. Uemori, and H. Tamehiro: ISIJ Int., 2004, vol. 44, pp. 1431-40.

W. Yan, Y.Y. Shan, and K. Yang: Metall. Mater. Trans. A, 2007, vol. 38A, pp. 1211-22.

B. Hutchinson, J. Hagström, O. Karlsson, D. Lindell, M. Tornberg, F. Lindberg, and M. Thuvander: Acta Mater., 2001, vol. 59, pp. 5845-58.

J. Kömi, L.P. Karjalainen, and D.A. Porter: in Encyclopedia of Iron, Steel, and Their Alloys (EISA), R. Colas and G.E. Totten, eds., CRC Press, Boca Raton, FL, 2015, vol. 2, pp. 1109–25.

S. Morito, H. Yoshida, T. Maki, and X. Huang: Mater. Sci. Eng. A, 2006, vols. 438–440, pp. 237-40.

X. Huang, S. Morito, N. Hansen, and T. Maki: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 3517-31.

J.W. Morris, Jr.: Mater. Res. Soc. Symp. Proc., 1999, vol. 539, p. 23-28.

T. Inoue, S. Matsuda, Y. Okamura, and K. Aoki: Trans. Jpn. Inst. Met., 1970, vol. 11, pp. 36-43.

T. Swarr and G. Krauss: Metall. Trans. A, 1976, vol. 7A, pp. 41-48.

Acknowledgments

The financial support of CBMM (Companhia Brasileira de Metalurgia e Mineração) and SSAB Europe Oy is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 11, 2017.

Rights and permissions

About this article

Cite this article

Hannula, J., Kömi, J., Porter, D.A. et al. Effect of Boron on the Strength and Toughness of Direct-Quenched Low-Carbon Niobium Bearing Ultra-High-Strength Martensitic Steel. Metall Mater Trans A 48, 5344–5356 (2017). https://doi.org/10.1007/s11661-017-4295-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-017-4295-3