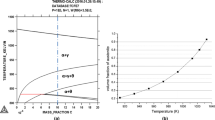

The growth of austenite during continuous heating was observed in situ under a confocal scanning laser microscope in Fe-Mn and Ni alloys containing less than 0.01 mass pct C. The advancements of the α/γ boundary were measured in the temperature range of ca. 40 K, which encompassed the Ae3 line of the alloys. Below Ae3, the growth rates were of the same order of magnitude as those predicted from the carbon diffusion-controlled negligible partition local equilibrium in the (α + γ) two-phase region, whereas those observed near and above the Ae3 were ca. two orders of magnitude greater. The α/γ boundary mobilities evaluated therefrom were somewhat smaller than those obtained previously in massive ferrite transformation during continuous cooling in the same alloys, albeit the experimental scatter was large and fell near the mobilities proposed in the literature. The α/γ boundary migrated probably with a carbon diffusion spike ahead of the boundary and the solute drag of the carbon or alloy element is unlikely to be operative during the growth of austenite.

Similar content being viewed by others

References

M. Hillert: Metall. Trans A, 1975, vol. 6A, pp. 5–19.

H.I. Aaronson, W.T. Reynolds, and G.R. Purdy: Metal. Mater. Trans. A, 2000, vol. 31A, pp. 379–85.

H.I. Aaronson, M. Enomoto, and J.K. Lee: Mechanisms of Diffusional Phase Transformations in Metals and Alloys, CRC Press, Boca Raton, FL, 2010, pp. 1–47.

G.P Krielaart, J. Sietsma, and S. van der Zwaag: Mater. Sci. Eng., 1997, vol. 237A, pp. 216–23.

J.J. Wits, T.A. Kop, T. van Leeuwen, J. Seitsma, and S. van der Zwaag: Mater. Sci. Eng. A, 2000, vol. 283, pp. 234–41.

S.I. Vooijs, Y. van. Leeuwen, J. Sietsma, and S.van der Zwaag: Metal. Mater. Trans. A, 2000, vol. 31A, pp. 379–85.

E. Kzeschnik and E. Gamsjäger: Metal. Mater. Trans. A, 2006, vol. 37A, pp. 1791–1797.

E. Gamsjäger, M. Wiessner, S. Shider, H. Chen, and S. Van der Zwaag: Phil. Mag., 2015, vol. 95, pp. 2899–917.

E. Gamsjäger, M. Militzer, F. Fazeli, J. Svoboda, and F.D. Fisher: Comp. Mater. Sci., 2006, vol. 37, pp. 94–100.

E. Gamsjäger, H. Chen, and S. Van der Zwaag: Comp. Mater. Sci., 2014, vol. 83, pp. 92–100.

J. Hamada, M. Enomoto, T. Fujishiro, and T. Akatsuka: Metal. Mater. Trans. A, 2014, vol. 45A, pp. 3781–89.

H. Chikama, H. Shibata, T. Emi, and M. Suzuki: Mater. Trans., JIM, 1996, vol. 37, pp. 620–26.

D. Phelan and R. Dippenaar: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 3701–16.

Thermo-calc is Trademark of Thermo-Calc Software: http://www.thermocalc.com/.

T.B. Massalski: Metall. Mater. Trans. A, 2002, vol. 33A, pp. 2277–83.

T.B. Massalski: Phase Transformations, ASM, Materials Park, OH, 1970, pp. 433–85.

G.R. Speich and M. Cohen: Trans. TMS-AIME, 1960, vol. 218, pp. 1050–59.

X.L. Wan, R. Wei, L. Cheng, M. Enomoto, and Y. Adachi: J. Mater. Sci., 2013, vol. 48, pp. 4345–55.

M. Enomoto: Acta Mater., 1999, vol. 47, pp. 3531–40.

K.M. Wu, M. Kagayama, and M. Enomoto: Mater.Sci.Eng., 2003, vol. A343, pp. 143–50.

H. Guo and M. Enomoto: Metal. Mater. Trans. A, 2007, vol. 38A, pp. 1152–61.

M. Enomoto: Metal. Mater. Trans. A, 2002, vol. 33A, pp. 2309–16.

J. Sietsma and S. van der Zwaag: Acta Mater., 2004, vol. 52, pp. 4143–52.

H.J. Lee and H.I. Aaronson: J. Mater. Sci., 1988, vol. 23, pp. 150–60.

H. Chen, B. Appolaire, and S. van der Zwaag: Acta Mater., 2011, vol. 59, pp. 6751–60.

M. Hillert and L. Höglund: Scripta Mater., 2006, vol. 54, pp. 1259–63.

Y.C. Liu, F. Sommer, and E.J. Mittemeijer: Phil.Mag., 2004, vol. 84, pp. 1853–76.

G.R. Speich and A. Szirmae: Trans. AIME, 1969, vol. 245, pp. 1063–74.

M. Enomoto and K. Hayashi: J. Mater. Sci, 2015, vol. 50, pp. 6786–93.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 20, 2016.

Rights and permissions

About this article

Cite this article

Enomoto, M., Wan, X.L. In Situ Observation of Austenite Growth During Continuous Heating in Very-Low-Carbon Fe-Mn and Ni Alloys. Metall Mater Trans A 48, 1572–1580 (2017). https://doi.org/10.1007/s11661-017-3961-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-017-3961-9