Abstract

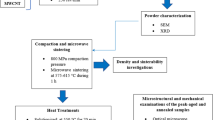

The performance of solid solution aging treatment on aluminum matrix composites prepared by powder metallurgy and reinforced with 6061 aluminum alloy powder as matrix; meanwhile, nano silicon carbide particles (nm SiCp), submicron silicon carbide particles (1 µm SiCp) and Ti particles were studied. The Al/SiCp composite powder was prepared by high-energy ball milling, and then cold-pressed, sintered, hot-extruded, and then heat-treated with different solution temperatures and aging times for the extruded composites. Optical microscopy, scanning electron microscopy, energy dispersive X-ray spectroscopy (EDS), X-ray diffractometer (XRD) and extrusion testing were used to analyze and test the microstructure and mechanical properties of aluminum matrix composites. The results show that after the multi-stage solid solution at 530 °C×2 h+535 °C×2 h+540 °C×2 h, the particles are mainly equiaxed grains and uniformly distributed. There is no reinforcement agglomeration, and the surface is dense and the insoluble phase is basically dissolved. In the matrix, the strengthening effect is good, and the hardness and compressive strength are 179.43 HV and 680.42 MPa, respectively. Under this solution process, when the aluminum matrix composites are aged at 170 °C for 10 h, the hardness and compressive strength can reach their peaks and increase to 195.82 HV and 721.48 MPa, respectively.

Similar content being viewed by others

References

Dyzia M. Aluminum Matrix Composite (AlSi7Mg2Sr0.03/SiCp) Pistons Obtained by Mechanical Mixing Method[J]. Materials, 2018, 11(1): 42

Chen B, Imai H, Umeda J, et al. Effect of Spark-Plasma-Sintering Conditions on Tensile Properties of Aluminum Matrix Composites Reinforced with Multiwalled Carbon Nanotubes (MWCNTs)[J]. JOM, 2017, 69(4): 669–675

Jafari M, Abbasi M H, Enayati M H, et al. Mechanical Properties of Nanostructured Al2024−MWCNT Composite Prepared by Optimized Mechanical Milling and Hot Pressing Methods[J]. Advanced Powder Technology, 2012, 23(2): 205–210

Asl A M, Khandani S T. Role of Hybrid Ratio in Microstructural, Mechanical and Sliding Wear Properties of the A15083/Graphitep/Al2O(3p) a Surface Hybrid Nanocomposite Fabricated Via Friction Stir Processing Method[J]. Materials Science & Engineering, 2013, 559(JAN. 1): 549–557

Nyanor P, El-Kady O, Yehia H M, et al. Effect of Bimodal-Sized Hybrid TiC−CNT Reinforcement on the Mechanical Properties and Coefficient of Thermal Expansion of Aluminium Matrix Composites[J]. Metals and Materials International, 2020, 27(4): 753–766

Zhang W, Chen C, Xu H, et al. The Role of Ti in the Preparation of SiC/7075 Aluminum Matrix Composite[J]. Journal of Wuhan University of Technology-Mater. Sci. Ed., 2020, 35(2): 293–298

Liu Y, Chen W, Chao Y, et al. Effects of Metallic Ti Particles on the Aging Behavior and the Influenced Mechanical Properties of Squeeze-cast (SiCp +Ti)/7075Al Hybrid Composites[J]. Materials Science and Engineering A, 2015, 620(JAN. 3): 190–197

Chen W, Liu Y, Chao Y, et al. (SiCp+Ti)/7075Al Hybrid Composites with High Strength and Large Plasticity Fabricated by Squeeze Casting[J]. Materials Science and Engineering A, 2014, 609: 250–254

Shahrdami L, Sedghi A, Shaeri M H. Microstructure and Mechanical Properties of Al Matrix Nanocomposites Reinforced by Different Amounts of CNT and SiCw[J]. Composites, 2019, 175(Oct.15): 107 081.1–107 081.11

Zhang X N, Geng L, Wang G S. Fabrication of Al-based Hybrid Composites Reinforced with SiC Whiskers and SiC Nanoparticles by Squeeze Casting[J]. Journal of Materials Processing Technology, 2006, 176(1–3): 146–151

Nassar A E, Nassar E E. Properties of Aluminum Matrix Nano Composites Prepared by Powder Metallurgy Processing[J]. Journal of King Saud University - Engineering Sciences, 2015, 29(3): 11 001

Md. Habibur Rahman, et al. Characterization of Silicon Carbide Reinforced Aluminum Matrix Composites[J]. Procedia Engineering, 2014, 90: 103–109

Chang S Y, Lee K S, Ryu S, et al. Effect of Equal Channel Angular Pressing on the Distribution of Reinforcements in the Discontinuous Metal Matrix Composites[J]. Materials Transactions Jim, 2002, 43(4): 757–761

Chak V, Chattopadhyay H, Dora T L. A Review on Fabrication Methods, Reinforcements and Mechanical Properties of Aluminum Matrix Composites[J]. Journal of Manufacturing Processes, 2020, 56(December 5 (86)): 1 059–1 074

Bodukuri A K, Eswaraiah K, Rajendar K, et al. Fabrication of Al-SiC-B4C Metal Matrix Composite by Powder Metallurgy Technique and Evaluating Mechanical Properties[J]. Perspectives in Science, 2016, 8(C): 428–431

Salama E I, Abbas A, Esawi A. Preparation and Properties of Dual-matrix Carbon Nanotube-reinforced Aluminum Composites[J]. Composites Part A: Applied Science and Manufacturing, 2017, 99: 84–93

Xu X, Mao Q, Jiang Z, et al. Effect of Multi-stage Solution and Aging Process on Microstructure and Properties of Al−11.2Zn−3.0Mg−1.3Cu−0.2Zr Aluminum Alloy Extrusion[J]. Materials Letters, 2019, 254(Nov.1): 375–378

Mungara SR, Manohar HS, Dubey S, et al. Investigating the Effect of Heat Treatment on B4C Reinforced Aluminum Metal Matrix Composites[J]. 2020, 45: 100–104

Sandeep Sharma, Suresh Kumar, Tarun Nanda, et al. Effect of Heat Treatment on the Wear Behavior of Zircon Reinforced Aluminium Matrix Composites[J]. Materials Research Express, 2019, 6(5), 056 535

Zhang X, Chen T. Toughening Mechanisms of Solution-treated SiCp/6061 Aluminum Matrix Composites Fabricated Via Powder Thixoforming[J]. Journal of Materials Research, 2018, 33(18): 1–13

Peng-**ang Zhang, Hong Yan, Wei Liu, et al. Effect of T6 Heat Treatment on Microstructure and Hardness of Nanosized Al2O3 Reinforced 7075 Aluminum Matrix Composites[J]. Metals, 2019, 9(1), 44

Long J, Zhang L J, Zhang L L, et al. Effects of Minor Zr Addition on the Microstructure and Mechanical Properties of Laser Welded Joint of Al/SiCp Metal-Matrix Composite[J]. Journal of Manufacturing Processes, 2020, 49(C): 373–384

Kim I S, Song M Y, Kim J H. Effects of Ti-B and Si Additions on Microstructure and Mechanical Properties of Al−Cu−Mg Based Aluminum Matrix Composites[J]. Journal of Alloys and Compounds, 2020, 832: 154 827

Mohammad Sharifi E, Enayati M H, Karimzadeh F. Fabrication and Characterization of Al-Al4C3 Nanocomposite by Mechanical Alloying[J]. International Journal of Modern Physics: Conference Series. World Scientific Publishing Company, 2012, 5: 480–487

Han N, Pollard G, Stevens R. Microstructural Characterisation of Sand Cast Aluminium Alloy A356-SiC Particle Metal Matrix Composite[J]. Materials Science and Technology, 1992, 8(1): 51–56

Liu XQ, Li CJ, Yi JH, et al. Enhancing the Interface Bonding in Carbon Nanotubes Reinforced Al Matrix Composites by the In Situ Formation of TiAl3 and TiC[J]. Journal of Alloys and Compounds, 2018, 765: 98–105

Lee J C, Lee H I, Ahn J P, et al. Methodology to Design the Interfaces in SiC/Al Composites[J]. Metallurgical and Materials Transactions A, 2001, 32: 1 541–1 550

Mitra R, Rao V S C, Maiti R, et al. Stability and Response to Rolling of the Interfaces in Cast Al-SiCp and Al-Mg Alloy-SiCp Composites[J]. Materials Science and Engineering: A, 2004, 379(1–2): 391–400

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

All authors declare that there are no competing interests.

Additional information

Funded by the Key Projects of Equipment Pre-research Foundation of the Ministry of Equipment Development of the Central Military Commission of China (No.6140922010201) and the Key R&D Plan of Zhenjiang in 2018(No.GY2018021)

Rights and permissions

About this article

Cite this article

Wu, J., Xu, X., Zhang, X. et al. Effect of Heat Treatment on Microstructure and Mechanical Properties of Multiscale SiCp Hybrid Reinforced 6061 Aluminum Matrix Composites. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 39, 174–181 (2024). https://doi.org/10.1007/s11595-024-2869-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-024-2869-7