Abstract

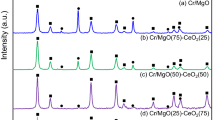

Carbon black and Cr2AlC were used as raw materials to obtain a large number of Cr3C2 nanosheets by means of the molten salt heat treatment at 1 100 °C for 1.5 hours. Results showed that carbon black can promote the decomposition of a large number of Cr2AlC to form Cr3C2 and Cr7C3 nanoparticles at 1 100 °C in the absence of molten salt. Under a molten salt environment, carbon black can promote the complete decomposition of Cr2AlC to form Cr3C2 and Cr7C3 nanosheets. The thickness of chromium carbide nanosheets is approximately 10–20 nm, and the length is approximately 100–200 nm. The addition of excess carbon black can promote the complete decomposition of Cr2AlC into a material with Cr3C2 as the main phase.

Similar content being viewed by others

References

Li Y, Gao Y, **ao B, et al. The Electronic, Mechanical Properties and Theoretical Hardness of chromium Carbides By First-Principles Calculations[J]. J. Alloy. Compd., 2011, 509(17): 5242–5249

Loubière S, Laurent CH, Bonino JP, et al. Elaboration, Microstructure and Reactivity of Cr3C2 Powders of Different Morphology[J]. Mater. Res. Bull., 1995, 30(12): 1535–1546

Detroye M, Reniers F, Herman CB, et al. Synthesis and Characterisation of Chromium Carbides[J]. Appl. Surf. Sci, 1997, 120(1–2): 85–93

Poetschke J, Richter V, Holke R. Influence and Effectivity of VC and Cr3C2 Grain Growth Inhibitors on Sintering of Binderless Tungsten Carbide[J]. Int. J. Refract. Met. Hard. Mater., 2012, 31:218–223

Laima L, Jia, YU, Shaoguang L, et al. Thermal Shock Resistances of Femncr/Cr3C2 Coatings Deposited by Arc Spraying[J]. J. Wuhan. Univer. Tech, 2010, 25(2): 243–247

Berger LM, Stolle S, Gruner W, et al. Investigation of the Carbothermal Reduction Process of Chromium Oxide by Micro- and Lab-Scale Methods[J]. Int. J. Refract. Met. Hard. Mater, 2001, 19(2): 109–121

Anacleto N, Ostrovski O. Solid-State Reduction of Chromium Oxide by Methane-Containing Gas[J]. Metall. Mater. Trans. B, 2004, 35(4): 609–615

Fantozzi D, Matikainen V, Uusitalo M, et al. Chlorine Induced High-Temperature Corrosion Mechanisms in HVOF and HVAF Sprayed Cr3C2-Based Hardmetal Coatings[J]. Corros. Sci., 2019, 160: 108166

Hirota K, Mitani K, Yishinaka M, et al. Simultaneous Synthesis and Consolidation of Chromium Carbides (Cr3C2, Cr7C3 And Cr23C6) by Pulsed Electric-Current Pressure Sintering[J]. Mater. Sci. Eng. A, 2005, 399(1–2): 154–160

Li L, Tang J. Synthesis of Cr7C3 and Cr3C2 by Mechanical Alloying[J]. J. All. Compd., 1994, 9: L1

Kunrath AO, Reimanis IE, Moore JJ. Combustion Synthesis of TiC−Cr3C2 Composites[J]. J. All. Compd., 2001, 329(1–2): 131–135

Novoselov KS, Geim AK, Morozov SV, et al. Electric Field Effect in Atomically Thin Carbon Films[J]. Science, 2004, 306: 666–669

Sedlák R, Kovalčíková A, Girman V, et al. Fracture Characteristics of SiC/Grapheme Platelet Composites[J]. J. Eur. Ceram. Soc., 2017, 37: 4307–4314

Yin ZB, Yuan JT, Xu WW, et al. Graphene Nanosheets Toughened TiB2-Based Ceramic Tool Material By Spark Plasma Sintering[J]. Ceram. Int., 2018, 44: 8977–8982

Luo GQ, Huang, J, **, ZP, et al. Study on Microstructure and Mechanical Performance of Cu−Sno2−MgO Based Composites Prepared by Plasma Activated Sintering[J]. J. Wuhan. Univer. Tech, 2015, 30(6):1152–1158

Selloni A, Carnevali P, Car R, et al. Localization, Hop**, and Diffusion of Electrons in Molten Salts[J]. Phys. Rev. Lett., 1987, 59(7): 823–826

Weng W, Wang M Y, Gong X Z, et al. Electrochemical Preparation of V2O3 from NaVO3 and Its Reduction Mechanism[J]. J. Wuhan. Univer. Tech., 2017, 32(5): 1019–1024

Chai ZN, Ding J, Deng CJ, et al. Ni-Catalyzed Synthesis of Hexagonal Plate-Like Alpha Silicon Nitride from Nitridation of Si Powder in Molten Salt Media[J]. Adv. Powd. Tech, 2016, 27: 1637–1644

Gai JL, Chen JX, Zhang H, et al. Synthesis of Al2OC Whiskers by Heat Treating Bulk Ti3AlC2 in A Carbon-Containing Environment[J]. Mat. Lett., 2016, 167:73–76

Racault C, Langlais F, Naslain R, et al. Solid-State Synthesis and Characterization of the Ternary Phase Ti3SiC2[J]. J. Mater. Sci., 1994, 29:3384–3392

Duong TC, Talapatra A, Son W, et al. On the Stochastic Phase Stability of Ti2AlC−Cr2AlC[J]. Sci. Rep., 2017, 5138: 1–7

Ye DL, HU JH. Practical Inorganic Thermodynamic Data Book[M]. Bei**g: Metallurgical Industry Publishing. 2002

Wang WJ, Gauthier-Brunet V, Bei GP, et al. Powder Metallurgy Processing and Compressive Properties of Ti3AlC2/Al Composites[J]. Mater. Sci. Eng. A, 2011, 530: 168–173

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the National Natural Science Foundation of China (No.51864028), Key Scientific and Technological Projects in Henan Province (No.212102210465), Key Scientific Research Project Plan of Colleges and Universities in Henan Province (No.22A430041, 22B430035), National Innovation and Entrepreneurship Training Program for College Students (No.202110465013), National Natural Science Foundation of China (No.U2030207)

Rights and permissions

About this article

Cite this article

Liang, B., Dai, Z., Zhang, W. et al. In-situ Synthesis of Cr3C2 Nanosheets by Carbon Reduction Route from Cr2AlC. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 37, 364–369 (2022). https://doi.org/10.1007/s11595-022-2540-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-022-2540-0