Abstract

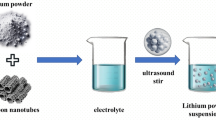

Reducing silicon particle size in lithium-ion battery anodes not only mitigates surface stress, prevents pulverization, and reduces SEI film cracking but also significantly enhances surface area, thereby amplifying the impact of particle surface chemistry on performance. In this study, the surface of silicon particles with 80-nm diameter were oxidized in air to prepare Si@SiOx with a core–shell structure. We investigated the effect of different oxidation levels of the shell on the cycling performance of the nanosized silicon particles. The results showed that longer heating times decreased initial coulombic efficiency (ICE) but improved cycling performance. An interesting phenomenon was observed that, when the oxidation level was high, fast charging reduced battery capacity; while at lower oxidation levels, fast charging maintained or even slightly increased battery capacity. Based on electrochemical analysis, we proposed an explanation for this phenomenon: for small-sized nanoparticles with a large specific surface area, the effect of potential is particularly significant. The oxidation level of the particle surface affects the impedance of the SEI film, and high charge/discharge rates will also produce bias voltage, both of the two factors will limit the formation of crystallized Li15Si4 (c-Li15Si4). Reducing the amount of c-Li15Si4 can effectively improve the cycling performance of the electrode, but excessive bias voltage will sacrifice the lithium storage capacity of the electrode. For the designing of small size silicon particles, both factors should be considered.

Similar content being viewed by others

Data availability

Data would be available from the corresponding author upon reasonable request.

References

Ko M, Chae S, Ma J et al (2016) Scalable synthesis of silicon-nanolayer-embedded graphite for high-energy lithium-ion batteries. Nat Energy 1:16113. https://doi.org/10.1038/nenergy.2016.113

Li P, Kim H, Myung S-T, Sun Y-K (2021) Diverting exploration of silicon anode into practical way: a review focused on silicon-graphite composite for lithium ion batteries. Energy Storage Mater 35:550–576. https://doi.org/10.1016/j.ensm.2020.11.028

Sun L, Liu Y, Shao R et al (2022) Recent progress and future perspective on practical silicon anode-based lithium ion batteries. Energy Storage Mater 46:482–502. https://doi.org/10.1016/j.ensm.2022.01.042

Shi J, Zu L, Gao H et al (2020) Silicon-based self-assemblies for high volumetric capacity Li-Ion batteries via effective stress management. Adv Funct Mater 30:2002980. https://doi.org/10.1002/adfm.202002980

Han X, Gu L, Sun Z et al (2023) Manipulating charge-transfer kinetics and a flow-domain LiF-rich interphase to enable high-performance microsized silicon–silver–carbon composite anodes for solid-state batteries. Energy Environ Sci 16:5395–5408. https://doi.org/10.1039/D3EE01696J

Han X, Zhou W, Chen M et al (2022) Interfacial nitrogen engineering of robust silicon/MXene anode toward high energy solid-state lithium-ion batteries. J Energy Chem 67:727–735. https://doi.org/10.1016/j.jechem.2021.11.021

Gu L, Han J, Chen M et al (2022) Enabling robust structural and interfacial stability of micron-Si anode toward high-performance liquid and solid-state lithium-ion batteries. Energy Storage Mater 52:547–561. https://doi.org/10.1016/j.ensm.2022.08.028

Huang G, Han J, Lu Z et al (2020) Ultrastable silicon anode by three-dimensional nanoarchitecture design. ACS Nano 14:4374–4382. https://doi.org/10.1021/acsnano.9b09928

Liu N, Lu Z, Zhao J et al (2014) A pomegranate-inspired nanoscale design for large-volume-change lithium battery anodes. Nat Nanotechnol 9:187–192

Wang Y, Li H, He P et al (2010) Nano active materials for lithium-ion batteries. Nanoscale 2:1294. https://doi.org/10.1039/c0nr00068j

Liu XH, Zhong L, Huang S et al (2012) Size-dependent fracture of silicon nanoparticles during lithiation. ACS Nano 6:1522–1531. https://doi.org/10.1021/nn204476h

Ryu I, Choi JW, Cui Y, Nix WD (2011) Size-dependent fracture of Si nanowire battery anodes. J Mech Phys Solids 59:1717–1730. https://doi.org/10.1016/j.jmps.2011.06.003

Dasari H, Eisenbraun E (2021) Predicting capacity fade in silicon anode-based Li-ion batteries. Energies 14:1448. https://doi.org/10.3390/en14051448

Dasari H, Eisenbraun E (2023) Predicting the effect of silicon electrode design parameters on thermal performance of a lithium-ion battery: original scientific paper. J Electrochem Sci Eng. https://doi.org/10.5599/jese.1558

Parekh MH, Sediako AD, Naseri A et al (2020) In situ mechanistic elucidation of superior Si-C-graphite Li-ion battery anode formation with thermal safety aspects. Adv Energy Mater 10:1902799. https://doi.org/10.1002/aenm.201902799

Tang J, Dysart AD, Kim DH et al (2017) Fabrication of carbon/silicon composite as lithium-ion anode with enhanced cycling stability. Electrochim Acta 247:626–633. https://doi.org/10.1016/j.electacta.2017.06.178

McDowell MT, Lee SW, Ryu I et al (2011) Novel size and surface oxide effects in silicon nanowires as lithium battery anodes. Nano Lett 11:4018–4025. https://doi.org/10.1021/nl202630n

Xun S, Song X, Wang L et al (2011) The effects of native oxide surface layer on the electrochemical performance of Si nanoparticle-based electrodes. J Electrochem Soc 158:A1260. https://doi.org/10.1149/2.007112jes

Xun S, Song X, Grass ME et al (2011) Improved initial performance of Si nanoparticles by surface oxide reduction for lithium-ion battery application. Electrochem Solid-state Lett 14:A61–A63. https://doi.org/10.1149/1.3559765

Yu B-C, Hwa Y, Park C-M et al (2013) Effect of oxide layer thickness to nano–Si anode for Li-ion batteries. RSC Adv 3:9408. https://doi.org/10.1039/c3ra41006d

Delpuech N, Mazouzi D, Dupré N et al (2014) Critical role of silicon nanoparticles surface on lithium cell electrochemical performance analyzed by FTIR, Raman, EELS, XPS, NMR, and BDS spectroscopies. J Phys Chem C 118:17318–17331. https://doi.org/10.1021/jp503949y

Henrion W, Rebien M, Angermann H, Röseler A (2002) Spectroscopic investigations of hydrogen termination, oxide coverage, roughness, and surface state density of silicon during native oxidation in air. Appl Surf Sci 202:199–205. https://doi.org/10.1016/S0169-4332(02)00923-6

Kim MK, Jang BY, Lee JS et al (2013) Microstructures and electrochemical performances of nano-sized SiOx (1.18 ≤ x ≤ 1.83) as an anode material for a lithium(Li)-ion battery. J Power Sources 244:115–121. https://doi.org/10.1016/j.jpowsour.2013.03.041

** Y, Zhu B, Lu Z et al (2017) Challenges and recent progress in the development of Si anodes for lithium-ion battery. Adv Energy Mater 7:1700715. https://doi.org/10.1002/aenm.201700715

Choi JW, Aurbach D (2016) Promise and reality of post-lithium-ion batteries with high energy densities. Nat Rev Mater 1:1–16. https://doi.org/10.1038/natrevmats.2016.13

Takezawa H, Iwamoto K, Ito S, Yoshizawa H (2013) Electrochemical behaviors of nonstoichiometric silicon suboxides (SiOx) film prepared by reactive evaporation for lithium rechargeable batteries. J Power Sources 244:149–157. https://doi.org/10.1016/j.jpowsour.2013.02.077

Chen T, Wu J, Zhang Q, Su X (2017) Recent advancement of SiOx based anodes for lithium-ion batteries. J Power Sources 363:126–144. https://doi.org/10.1016/j.jpowsour.2017.07.073

Philippe B, Dedryvère R, Allouche J et al (2012) Nanosilicon electrodes for lithium-ion batteries: interfacial mechanisms studied by hard and soft X-ray photoelectron spectroscopy. Chem Mater 24:1107–1115. https://doi.org/10.1021/cm2034195

Kim JS, Pfleging W, Kohler R et al (2015) Three-dimensional silicon/carbon core–shell electrode as an anode material for lithium-ion batteries. J Power Sources 279:13–20. https://doi.org/10.1016/j.jpowsour.2014.12.041

Kitada K, Pecher O, Magusin PCMM et al (2019) Unraveling the reaction mechanisms of SiO anodes for Li-ion batteries by combining in situ 7 Li and ex situ 7 Li/ 29 Si solid-state NMR spectroscopy. J Am Chem Soc 141:7014–7027. https://doi.org/10.1021/jacs.9b01589

Ogata K, Salager E, Kerr CJ et al (2014) Revealing lithium–silicide phase transformations in nano-structured silicon-based lithium ion batteries via in situ NMR spectroscopy. Nat Commun 5:3217. https://doi.org/10.1038/ncomms4217

**ao Y, Hao D, Chen H et al (2013) Economical synthesis and promotion of the electrochemical performance of silicon nanowires as anode material in Li-Ion Batteries. Acs Appl Mater Interfaces 5:1681–1687. https://doi.org/10.1021/am302731y

Cao Y, Bennett JC, Dunlap RA, Obrovac MN (2018) A simple synthesis route for high-capacity SiO x anode materials with tunable oxygen content for lithium-ion batteries. Chem Mater 30:7418–7422. https://doi.org/10.1021/acs.chemmater.8b02977

Cao Y, Dunlap RA, Obrovac MN (2020) Electrochemistry and thermal behavior of SiO x made by reactive gas milling. J Electrochem Soc 167:110501. https://doi.org/10.1149/1945-7111/ab9e83

Liu XH, Wang JW, Huang S et al (2012) In situ atomic-scale imaging of electrochemical lithiation in silicon. Nat Nanotechnol 7:749–756. https://doi.org/10.1038/nnano.2012.170

Cubuk ED, Kaxiras E (2014) Theory of structural transformation in lithiated amorphous silicon. Nano Lett 14:4065–4070. https://doi.org/10.1021/nl5015525

Chevrier VL, Liu L, Le DB et al (2014) Evaluating Si-based materials for Li-Ion batteries in commercially relevant negative electrodes. J Electrochem Soc 161:A783–A791. https://doi.org/10.1149/2.066405jes

Nguyen CC, Lucht BL (2014) Comparative study of fluoroethylene carbonate and vinylene carbonate for silicon anodes in lithium ion batteries. J Electrochem Soc 161:A1933. https://doi.org/10.1149/2.0731412jes

Tang J, Hou L, Hu T et al (2021) Influence of oxygen content on the electrochemical behavior of SiOx@C anodes for Li-ion battery. Compos Commun 23:100544. https://doi.org/10.1016/j.coco.2020.100544

Ratynski M, Hamankiewiecz B, Krajewski M et al (2020) Electrochemical impedance spectroscopy characterization of silicon-based electrodes for Li-ion batteries. Electrocatalysis 11:160–169

Fan S, Zhou X, Tang J et al (2022) Insights to the variation of oxygen content and reasons for improved electrochemical performance of annealing SiOx anodes for Li-ion battery. Appl Surf Sci 579:152179. https://doi.org/10.1016/j.apsusc.2021.152179

Wu B, Lu W (2017) Mechanical modeling of particles with active core–shell structures for lithium-ion battery electrodes. J Phys Chem C 121:19022–19030. https://doi.org/10.1021/acs.jpcc.7b05096

Funding

We gratefully acknowledge the financial support from the Natural Science Foundation of Zhejiang Province (LZ22E060001), Natural Science Foundation of Zhejiang Province (No. ZCLQ24E0101), and Zhejiang Science and Technology Plan Project (No. 2022C01199). We also thank the Instrumental Analysis Center of Shanghai Jiao Tong University for material characterization.

Author information

Authors and Affiliations

Contributions

LG contributed to experiment operation, data analysis and interpretation, and manuscript preparation. WL and HG contributed to the conceptualization and design of the study. JJ and MW contributed to data collection. CY and LL contributed equally to data verification and language modification of the manuscript. All authors have read and approved the final version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gao, L., Li, W., Jiang, J. et al. Effect of surface oxidation on the performance of silicon nanoparticles. Ionics (2024). https://doi.org/10.1007/s11581-024-05608-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11581-024-05608-z