Abstract

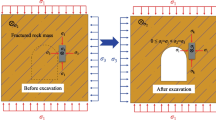

For deep hard–brittle rock mass engineering in a complicated hydrogeological environment, deformation and damage of the surrounding rock during excavation are often driven by the combined action of the dynamic seepage water and the strong unloading effect. To investigate the failure mechanism of a deep-buried rock mass under high seepage water pressure and high unloading rate, a series of conventional triaxial and unloading triaxial compression tests at different seepage water pressures and unloading rates were conducted on Erlang Mountain granite. The results confirmed that the dynamic seepage water pressure has a great influence on the mechanical properties and failure mechanism of rock because its splitting and expanding effects could stimulate crack generation and accelerate fractures. As the water pressure increased, the granite entered the nonlinear growth phase of the permeability coefficient earlier and entered the energy softening stage later. While the compressive strength and energy storage capacity of the rock were weakened gradually by dynamic seepage water, the permeability, energy hardening properties, and brittle failure mechanism could be magnified. Moreover, the effect of the strong unloading on the mechanical properties and damage mechanism of deep-buried granite was similar to that of the dynamic water pressure. Although the peak stress, peak strain, and energy storage capacity were reduced under the strong unloading effect, the permeability, brittle fracture characteristics, energy hardening properties and energy release rate could be significantly enhanced. Under the combined action of high seepage pressure and high unloading rate, the rock gradually decreased in hardness and increased in brittleness, and these changes were conducive to the instantaneous release of elastic strain energy in the failure stage.

Similar content being viewed by others

References

Aker E, Kühn D, Vavrycuk V, Soldal M, Oye V (2014) Experimental investigation of acoustic emissions and their moment tensors in rock during failure. Int J Rock Mech Min Sci 70:286–295

Chen GQ, Li TB, Wang W, Zhu ZF, Chen ZQ, Tang OL (2019) Weakening effects of the presence of water on the brittleness of hard sandstone. Bull Eng Geol Environ 78:1471–1483

Chen ZQ, He C, Wu D, Xu GW, Yang WB (2017) Fracture evolution and energy mechanism of deep-buried carbonaceous slate. Acta Geotech 12(6):1243–1260

Chen ZQ, He C, Ma GY, Xu GW, Ma CC (2019) Energy damage evolution mechanism of rock and its application to brittleness evaluation. Rock Mech Rock Eng 52:1265–1274

Chen ZQ, He C, Yang WB, Guo WQ, Li Z, Xu GW (2020) Impacts of geological conditions on instability causes and mechanical behavior of large-scale tunnels: a case study from the Sichuan-Tibet highway, China. Bull Eng Geol Environ 79:3667–3688

Chen ZQ, He C, Hu XY, Ma CC (2021) Effect of stress paths on failure mechanism and progressive damage of hard-brittle rock. J Mt Sci 18:2486–2502

Du YT, Li TC, Li WT et al (2020) Experimental study of mechanical and permeability behaviors during the failure of sandstone containing two preexisting fissures under triaxial compression. Rock Mech Rock Eng 53:3673–3697

Fan XM, Juang CH, Wasowski J, Huang RQ, Xu Q, Scaringi G, van Westen CJ, Havenith HB (2018) What we have learned from the 2008 wenchuan earthquake and its aftermath: a decade of research and challenges. Eng Geol 241:25–32

Fan Y, Lu WB, Zhou YH, Yan P, Leng ZD, Chen M (2016) Influence of tunneling methods on the strainburst characteristics during the excavation of deep rock masses. Eng Geol 201:85–95

Feng XT, Kong R, Zhang XW, Yang CX (2019) Experimental study of failure differences in hard rock under true triaxial compression. Rock Mech Rock Eng 52:2109–2122

Feng XT, Xu H, Qiu SL, Li SJ, Yang CX, Guo HS, Cheng Y, Gao YH (2018) In situ observation of rock spalling in the deep tunnels of the China ** underground laboratory (2400 m depth). Rock Mech Rock Eng 51(4):1193–1213

Hashiba K, Fukui K, Kataoka M (2019) Effects of water saturation on the strength and loading-rate dependence of andesite. Int J Rock Mech Min Sci 117:142–149

Hua ZA, You MQ (2001) Rock failure due to energy release during unloading and application to underground rock burst control. Tunn Undergr Space Technol 16(3):241–246

Huang D, Li YR (2014) Conversion of strain energy in triaxial unloading tests on marble. Int J Rock Mech Min Sci 66:160–168

Huang RQ, Wang Z, Pei SP, Wang YS (2009) Crustal ductile flow and its contribution to tectonic stress in Southwest China. Tectonophysics 473(3):476–489

Jiang Q, Feng XT, Fan YL, Fan QX, Liu GF, Pei SF, Duan SQ (2017) In situ, experimental investigation of basalt spalling in a large underground powerhouse cavern. Tunn Undergr Space Technol 68:82–94

Jiang Q, Feng XT, **ang TB, Su GS (2010) Rockburst characteristics and numerical simulation based on a new energy index: a case study of a tunnel at 2500 m depth. Bull Eng Geol Environ 69(3):381–388

Krzaczek M, Nitka M, Kozicki J et al (2020) Simulations of hydro-fracking in rock mass at meso-scale using fully coupled DEM/CFD approach. Acta Geotech 15:297–324

Li DY, Sun Z, **e T, Li XB, Ranjith PG (2017) Energy evolution characteristics of hard rock during triaxial failure with different loading and unloading paths. Eng Geol 228:270–281

Li TB, Ma CC, Zhu ML, Meng LB, Chen GQ (2017) Geomechanical types and mechanical analyses of rockbursts. Eng Geol 222:72–83

Lin BQ, Zou QL, Liang YP, **e J, Yang HM (2018) Response characteristics of coal subjected to coupling static and waterjet impact loads. Int J Rock Mech Min Sci 103:155–167

Martin CD, Chandler NA (1994) The progressive fracture of Lac du Bonnet granite. Int J Rock Mech Min Sci 31(6):643–659

Massart TJ, Selvadurai APS (2014) Computational modelling of crackinduced permeability evolution in granite with dilatant cracks. Int J Rock Mech Min Sci 70:593–604

Noorian Bidgoli M, **g L (2015) Water pressure effects on strength and deformability of fractured rocks under low confining pressures. Rock Mech Rock Eng 48:971–985

Ning ZX, Xue YG, Li ZQ et al (2022) Damage characteristics of granite under hydraulic and cyclic loading-unloading coupling condition. Rock Mech Rock Eng. https://doi.org/10.1007/s00603-021-02698-3

Shimizu H, Murata S, Ishida T (2011) The distinct element analysis for hydraulic fracturing in hard rock considering fluid viscosity and particle size distribution. Int J Rock Mech Min Sci 48:712–727

Tomac I, Gutierrez M (2017) Coupled hydro-thermo-mechanical modeling of hydraulic fracturing in quasi-brittle rocks using BPMDEM. J Rock Mech Geotech Eng 9:92–104

**e HP, Ju Y, Li LY, Peng RD (2008) Energy mechanism of deformation and failure of rock masses. Chin J Rock Mech Eng 27(9):1729–1739

Xu H, Feng XT, Yang CX, Zhang XW, Zhou YY, Wang ZF (2019) Influence of initial stresses and unloading rates on the deformation and failure mechanism of ** marble under true triaxial compression. Int J Rock Mech Min Sci 117:90–104

Xu NW, Li TB, Dai F, Zhang R, Tang CA, Tang LX (2016) Microseismic monitoring of strainburst activities in deep tunnels at the **** Ii Hydropower Station, China. Rock Mech Rock Eng 49:981–1000

Wang Q, Hu XL, Zheng WB et al (2021) Mechanical properties and permeability evolution of red sandstone subjected to hydro-mechanical coupling: experiment and discrete element modelling. Rock Mech Rock Eng 54:2405–2423

Zhou KP, Liu TY, Hu ZX (2018) Exploration of damage evolution in marble due to lateral unloading using nuclear magnetic resonance. Eng Geol 244:75–85

Zhou ZH, Chen ZQ, He C, Kou H (2021) Investigation on the evolution characteristics and transfer mechanism of surrounding rock pressure for a hard-rock tunnel under high geo-stress: case study on the Erlang Mountain Tunnel, China. Bull Eng Geol Environ 80:8339–8361

Zhuang L, Kim KY, Jung SG et al (2019) Effect of water infiltration, injection rate and anisotropy on hydraulic fracturing behavior of granite. Rock Mech Rock Eng 52:575–589

Acknowledgements

This research was supported by the National Natural Science Foundation of China (Nos. 52008351 and U19A200566), the Sichuan Science and Technology Program (Nos. 2021YJ0539 and 2021JDR0399), the project funded by China Postdoctoral Science Foundation (Nos. 2020TQ0250 and 2021M700112), the Open Foundation of State Key Laboratory of Geohazard Prevention and Geoenvironment Protection (Chengdu University of Technology) (No. SKLGP2021K019) and the Fundamental Research Funds for the Central Universities (No. 2682021CX013).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that we have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, Z., Ma, C., Li, T. et al. Experimental investigation of the failure mechanism of deep granite under high seepage water pressure and strong unloading effect. Acta Geotech. 17, 5009–5030 (2022). https://doi.org/10.1007/s11440-022-01665-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-022-01665-8