Abstract

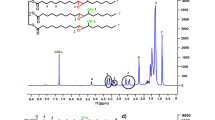

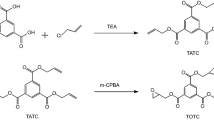

In this study, a novel bio-based thermosetting system has been developed from epoxy resin (EP), with rosin-sourced anhydrides (maleopimaric acid, RAM) as curing agent and imidazole type latent catalyst (two amino imidazole salt complex, IMA), to be used as matrix for hot-melt prepreg curing at mid-temperature. For comparison, the epoxy resin system with petroleum sourced hardener methylhexahydrophthalicanhydride (MHHPA) was also examined. The curing behaviour and mechanism were investigated by non-isothermal differential scanning calorimeter (DSC) analysis and Fourier transform infrared (FTIR) spectra. The results showed that the curing course of bio-based epoxy resin system containing RAM included two stages, which were the reaction between the free carboxyl group of RAM and oxirane ring under the acceleration of IMA, and the main reaction attributed to the reaction between anhydride and oxirane. According to Kissinger method, the reaction activation energy (E a ) of two stages were 68.9 and 86.5 kJ mol‒1, respectively. The E a of EP/MHHPA and EP/IMA resin system were 81.04 and 77.9 kJ mol‒1. The processing property of EP/RAM/IMA system, i.e. the relationship between viscosity-temperature-time, was characterized by cone-plate viscometer aim to decide the processing parameter of prepreg preparation. The effect of RAM content on mechanical performance and dynamic mechanical property was investigated. Noteworthily, compared with the laminates with EP/MHHPA as matrix, the laminates with RAM as hardeners achieved a 44%, 73% and 70°C increase in bending strength, bending modulus and the glass transition temperature, respectively, due to the bulky hydrogenated phenanthrene ring structure incorporated into the cross-linking networks. When the fiber volume fraction reached 47%, the mechanical property of the laminates prepared with hot melt prepreg was superior or comparable to that of composites with pure petroleum sourced matrix. RAM as cross-linking agent of epoxy resin holds a great potential to satisfy the requirement of composites such as structure and secondary structure parts preparation.

Similar content being viewed by others

References

Lyu M Y, Choi T G. Research trends in polymer materials for use in lightweight vehicles. Int J Precis Eng Man, 2015, 16: 213–220

Wan J T, Zhao J Q, Gan B, et al. Ultrastiff biobased epoxy resin with high Tg and low permittivity: From synthesis to properties. ACS Sust Chem Eng, 2016, 4: 2869–2880

Ma S Q, Li T T, Liu X Q, et al. Research progress on bio-based thermosetting resins. Polym Int, 2016, 65: 164–173

Brocas A L, Llevot A, Mantzaridis C, et al. Epoxidized rosin acids as co-precursors for epoxy resins. Des Monomers Polym, 2014, 17: 301–310

Liu X Q, Zhang J W. High-performance biobased epoxy derived from rosin. Polym Int, 2010, 88

Baroncini E A, Kumar Yadav S, Palmese G R, et al. Recent advances in bio-based epoxy resins and bio-based epoxy curing agents. J Appl Polym Sci, 2016, 133

Auvergne R, Caillol S, David G, et al. Biobased thermosetting epoxy: Present and future. Chem Rev, 2014, 114: 1082–1115

Ding C, Matharu A S. Recent developments on biobased curing agents: A review of their preparation and use. ACS Sust Chem Eng, 2014, 2: 2217–2236

Liu K, Madbouly S A, Kessler M R. Biorenewable thermosetting copolymer based on soybean oil and eugenol. Eur Polym J, 2015, 69: 16–28

Wang H H, Liu B, Liu X Q, et al. Synthesis of biobased epoxy and curing agents using rosin and the study of cure reactions. Green Chem, 2008, 10: 1190–1196

Wang H H, Wang H W, Zhou G Y. Synthesis of rosin-based imidoamine- type curing agents and curing behavior with epoxy resin. Polym Int, 2011, 60: 557–563

Wang H H, Liu X Q, Liu B, et al. Synthesis of rosin-based flexible anhydride-type curing agents and properties of the cured epoxy. Polym Int, 2009, 58: 1435–1441

Mustata F R, Tudorachi N. Epoxy resins cross-linked with rosin adduct derivatives. Cross-linking and thermal behaviors. Ind Eng Chem Res, 2010, 49: 12414–12422

Deng L L, Ha C Y, Sun C N, et al. Properties of bio-based epoxy resins from rosin with different flexible chains. Ind Eng Chem Res, 2013, 52: 13233–13240

El-Ghazawy R A, El-Saeed A M, Al-Shafey H I, et al. Rosin based epoxy coating: Synthesis, identification and characterization. Eur Polymer J, 2015, 69: 403–415

Liu X Q, **n W B, Zhang J W. Rosin-based acid anhydrides as alternatives to petrochemical curing agents. Green Chem, 2009, 11: 1018–1025

Kudo K, Fuse S, Furutani M, et al. Imidazole-type thermal latent curing agents with high miscibility for one-component epoxy thermosetting resins. J Polym Sci Pol Chem, 2016, 54: 2680–2688

Yen W P, Chen K L, Yeh M Y, et al. Investigation of soluble PEGimidazoles as the thermal latency catalysts for epoxy-phenolic resins. J Taiwan Inst Chem Eng, 2016, 59: 98–105

Lei D F, Ma W S, Wang L F, et al. Preparation of 2-ethyl-4-methylimidazole derivatives as latent curing agents and their application in curing epoxy resin. J Appl Polym Sci, 2015, 132

Naumann S, Speiser M, Schowner R, et al. Air stable and latent single-component curing of epoxy/anhydride resins catalyzed by thermally liberated N-heterocyclic carbenes. Macromolecules, 2014, 47: 4548–4556

** F L, Li X, Park S J. Synthesis and application of epoxy resins: A review. J Ind Eng Chem, 2015, 29: 1–11

Rahul R, Kitey R. Effect of cross-linking on dynamic mechanical and fracture behavior of epoxy variants. Compos Part B-Eng, 2016, 85: 336–342

Sun G, Sun H, Liu Y, et al. Comparative study on the curing kinetics and mechanism of a lignin-based-epoxy/anhydride resin system. Polymer, 2007, 48: 330–337

Okabe T, Oya Y, Tanabe K, et al. Molecular dynamics simulation of crosslinked epoxy resins: Curing and mechanical properties. Eur Polym J, 2016, 80: 78–88

Sun H, Sun G, Lv H, et al. DSC study on the effect of cure reagents on the lignin base epoxy cure reaction. J Appl Polym Sci, 2007, 105: 2332–2338

Vyazovkin S. Is the Kissinger Equation applicable to the processes that occur on cooling? Macromol Rapid Comm, 2002, 23: 771–775

Ren R, **ong X, Ma X, et al. Isothermal curing kinetics and mechanism of DGEBA epoxy resin with phthalide-containing aromatic diamine. Thermochim Acta, 2016, 623: 15–21

Jiang B, Huang Y D, He S, et al. Quality analysis and control strategies for epoxy resin and prepreg. TrAC Trends Anal Chem, 2015, 74: 68–78

Sbirrazzuoli N, Vyazovkin S. Learning about epoxy cure mechanisms from isoconversional analysis of DSC data. Thermochim Acta, 2002, 388: 289–298

Bakare F O, Ramamoorthy S K, Åkesson D, et al. Thermomechanical properties of bio-based composites made from a lactic acid thermoset resin and flax and flax/basalt fibre reinforcements. Compos Part A-Appl S, 2016, 83: 176–184

Saba N, Jawaid M, Alothman O Y, et al. A review on dynamic mechanical properties of natural fibre reinforced polymer composites. Constr Build Mater, 2016, 106: 149–159

Liu J, Tang J, Wang X, et al. Synthesis, characterization and curing properties of a novel cyclolinear phosphazene-based epoxy resin for halogen-free flame retardancy and high performance. RSC Adv, 2012, 2: 5789

Bellenger V, Dhaoui W, Verdu J, et al. Internal antiplasticization in diglycidyl ether of bisphenol A diamino diphenyl methane non-stoichiometric epoxy networks. Polym Eng Sci, 1990, 30: 321–325

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, X., Wu, Y., Wei, J. et al. Curing kinetics and mechanical properties of bio-based composite using rosin-sourced anhydrides as curing agent for hot-melt prepreg. Sci. China Technol. Sci. 60, 1318–1331 (2017). https://doi.org/10.1007/s11431-016-9029-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-016-9029-y