Abstract

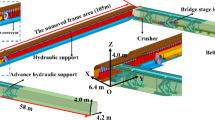

In order to ensure safe production and occupational health at a large-mining-height fully mechanized mining face in a coal mine, the present study firstly establishes an airflow-dust coupled model based on gas/solid two-phase flow equations and combines numerical simulation and field measurement for analyzing the dispersion pattern of dust particles with various sizes for different coal cutter locations. Results show that, due to the existence of drums, airflow deviates from the original direction and enters the footway. Driven by the airflow, dust particles enter the footway at different locations depending on coal cutter locations. The coal-cutting location (denoted as Prl) and the location where dust particles enter the footway (denoted as Pdt) are correlated as follows: Pdt(Prl) = − 0.0007Prl2 + 1.0343Prl − 3.3536. When Prl < 55 m, dust particles produced by the rear drum during coal cutting enter the footway earlier than those produced by the front drum, leading to the first and second dust concentration peaks in respiratory zones of footway. Dust suppression effects are assessed in these regions based on the first and second dust concentration peaks. Due to the superposition of the concentration fields associated with dust particles 2.5, 7, and 20 μm in diameter, dust concentration 25 m down the leeward side of the coal cutter can reach 1440 mg/m3. The concentration of dust particles with a diameter of 40 μm drops steadily and approaches 0 at the return corner. The dust particles 80 μm in diameter are fully settled within 22 m down the leeward side of the coal cutter. A comparison with the field measurement indicates that the present simulation results are highly accurate.

Graphical abstract

Similar content being viewed by others

References

Cheng W, Nie W, Qi Y, Yao Y (2012) Research on diffusion rule of dust pollution in coal mine whole-rock fully mechanized workface. J Converg Inf Technol 7:728–736

Cheng W, Yu H, Zhou G, Nie W (2016) The diffusion and pollution mechanisms of airborne dusts in fully-mechanized excavation face at mesoscopic scale based on CFD-DEM. Process Saf Environ Prot 104:240–253

Cheng WM, Hu XM, **e J, Zhao YY (2017) An intelligent gel designed to control the spontaneous combustion of coal: fire prevention and extinguishing properties. Fuel 210:826–835

Cong T, Jiang ZA, Chen JS, Pei W (2014) Numerical simulation of influencing factors on dust movement during coal cutting at fully mechanized working faces. J Univ Sci Technol Bei**g 36:716–721

Courtney WG, Cheng L, Divers EF (1986) Deposition of respirable coal dust in an airway. Report of investigations/1986. Chinese J Pathophysiol 17:1175–1178

Ding C, He XQ, Nie BS (2017) Numerical simulation of airflow distributionin mine tunnels. Int J Min Sci Technol 27(4):663–667

Fan T, Zhou G, Wang J (2018) Preparation and characterization of a wetting-agglomeration-based hybrid coal dust suppressant. Process Saf Environ Prot 113:282–291

Hodkinson JR (1960) The relation between ventilation airspeed and respirable airborne-dust concentration in coalmines. Colliery Eng

Hu ZX, Hu XM, Cheng WM, Lu W (2017) Influence of synthetic conditions on the performance of melamine–phenol–formaldehyde resin microcapsules. High Perform Polym 095400831875848

Jia M, Fu Y, Yuan Y, Wei H, Sun S, Li J (2016) Migration law of respirable dust on a super-long fully mechanized double-shearer working face. Int J Min Sci Technol 26:1109–1115

Klemens R, Kosinski P, Wolanski P, Korobeinikov VP, Markov VV, Menshov IS, Semenov IV (2001) Numerical study of dust lifting in a channel with vertical obstacles. J Loss Prev Process Ind 14:469–473

Kurnia J, Candra et al (2014) Dust dispersion and management in underground mining faces. Int J Min Sci Technol 24:39–44

Liang YP, Li B, Yuan Y et al (2017) Moving type of key strata and its influence on ground pressure in fully mechanized mining face with large mining height. J China Coal Soc 42:1380–1391

Liu Y, Jiang Z, Cai W et al (2007) Numerical simulation of the dust movement rule in fully-mechanized coal faces. J Univ Sci Technol Bei**g 29:351–353+362

Liu Z, Cheng K, Li H, et al (2017a) Exploring the potential relationship between indoor air quality and the concentration of airborne culturable fungi: a combined experimental and neural network modeling study. Environ Sci Pollut Res 1–8

Liu Z, Li H, Cao G (2017b) Quick estimation model for the concentration of indoor airborne culturable bacteria: an application of machine learning. Int J Environ Res Public Health 14:857

Liu Q, Nie W, Hua Y, Peng H, Liu Z (2018) The effects of the installation position of a multi-radial swirling air-curtain generator on dust diffusion and pollution rules in a fully-mechanized excavation face: a case study. Powder Technol 329:371–385

Nie W, Liu Y, Wei W, Hu X, Ma X, Peng H (2016) Effect of suppressing dust by multi-direction whirling air curtain on fully mechanized mining face. Int J Min Sci Technol 26:629–635

Nie W, Wei W, Liu Q et al (2018) Simulation experiments on the controllability of dust diffusion by means of multi-radial vortex airflow. Adv Powder Technol 29:835–847

Niu W, Jiang Z, Liu Y (2010) Numerical simulation on dust movement regularities at fully-mechanized coal faces and its utilization. J Liaoning Tech Univ 29:357–360

Patankar NA, Joseph DD (2001) Modeling and numerical simulation of particulate flows by the Eulerian–Lagrangian approach. Int J Multiph Flow 27:1659–1684

Petrov T, Wala AM, Huang G (2014) Parametric study of airflow separation phenomenon at face area during deep cut continuous mining. Min Technol 122:208–214

Ren T, Wang Z, Cooper G (2014) CFD modelling of ventilation and dust flow behaviour above an underground bin and the design of an innovative dust mitigation system. Tunn Undergr Sp Technol 41:241–254

Sa Z, Li F, Qin B, Pan X (2012) Numerical simulation study of dust concentration distribution regularity in cavern stope. Saf Sci 50:857–860

Sasmito AP, Birgersson E, Ly HC, Mujumdar AS (2013) Some approaches to improve ventilation system in underground coal mines environment—a computational fluid dynamic study. Tunn Undergr Sp Technol 34:82–95

Shi XX, Jiang ZA, Zhou SY, Cai W (2008) Experimental study on dust distribution regularity of fully mechanized mining face. J China Coal Soc 33:1117–1121

Toraño J, Torno S, Menéndez M, Gent M (2011) Auxiliary ventilation in mining roadways driven with roadheaders: validated CFD modelling of dust behaviour. Tunn Undergr Sp Technol 26:201–210

Wang P, Feng T, Liu R (2011) Numerical simulation of dust distribution at a fully mechanized face under the isolation effect of an air curtain. Int J Min Sci Technol 21:65–69

Wang J, Yang S, Kong D (2016) Failure mechanism and control technology of longwall coalface in large-cutting-height mining method. Int J Min Sci Technol 26:111–118

Wang H, Cheng W, Sun B, Ma Y (2017a) Effects of radial air flow quantity and location of an air curtain generator on dust pollution control at fully mechanized working face. Adv Powder Technol 28:1780–1791

Wang H, Nie W, Cheng W et al (2017b) Effects of air volume ratio parameters on air curtain dust suppression in a rock tunnel’s fully-mechanized working face. Adv Powder Technol 29:230–244

Yu H, Cheng W, Wu L, Wang H, **e Y (2017) Mechanisms of dust diffuse pollution under forced-exhaust ventilation in fully-mechanized excavation faces by CFD-DEM. Powder Technol 317:31–47

Zhang G, Shang S, Wu W (2014) Coal dust concentration distribution of fully-excavating working face by modeling analysis. J Liaoning Tech Univ 33:456–460

Zhang Q, Zhou G, Qian X, Yuan M, Sun Y, Wang D (2018) Diffuse pollution characteristics of respirable dust in fully-mechanized mining face under various velocities based on CFD investigation. J Clean Prod 184:239–250

Zhou G, Zhang Q, Bai R, Fan T, Wang G (2017) The diffusion behavior law of respirable dust at fully mechanized caving face in coal mine: CFD numerical simulation and engineering application. Process Saf Environ Prot 106:117–128

Zhou G, Ma Y, Fan T, Wang G (2018) Preparation and characteristics of a multifunctional dust suppressant with agglomeration and wettability performance used in coal mine. Chem Eng Res Des 132:729–742

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Marcus Schulz

Rights and permissions

About this article

Cite this article

**e, Y., Cheng, W., Yu, H. et al. Microscale dispersion behaviors of dust particles during coal cutting at large-height mining face. Environ Sci Pollut Res 25, 27141–27154 (2018). https://doi.org/10.1007/s11356-018-2735-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-018-2735-2