Abstract

Background

Residual stresses exist in many manufactured materials and must be measured and taken into account for safe structural design. Established residual stress measurement methods are either destructive or require substantial material-dependent calibration.

Objective

The present work is aimed at develo** an indentation-based method for measuring residual stress that causes minimal specimen damage, does not require a stress-free reference specimen, and has the capability to identify both the size and direction of the surface residual stresses. In this initial study, the simpler case of equi-biaxial stresses is addressed in preparation for subsequent general stress evaluations.

Methods

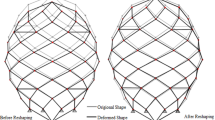

The surface displacements around an indentation made by a conical indenter are measured using digital image correlation. The residual stresses are then identified by comparison to the results of a finite model of the indentation process.

Results

The proposed method is shown to 2–5 times more sensitive to the presence of residual stresses than other commonly used indentation methods, particularly for materials with low Hollomon exponent n. In example measurements, axi-symmetric residual stresses were determined within 8% of the material yield stress.

Conclusions

The initial study presented here successfully considered the equal-biaxial stress case. The proposed method is attractive for future development because it gives directional information and therefore can be extended to the general non-equal-biaxial case.

Similar content being viewed by others

References

Withers PJ, Bhadeshia HKDH (2001) Residual stress. Part 2-Nature and origins. Mater Sci Technol 17(4):366–375

Schajer GS (2013) Practical residual stress measurement methods. John Wiley & Sons, Ltd, p 18

Noyan IC, Cohen JB (1987) Residual stress - measurement by diffraction and interpretation. Materials Research and Engineering. Springer, New York, Chap 5, p 117

Buttle DJ, Scruby CB, Briggs GAD, Jakubovics JP (1987) The measurement of stress in steels of varying microstructure by magnetoacoustic and Barkhausen emission. Proc R Soc Lond A 414(1847):469–497

Hutchings MT, Withers PJ, Holden TM, Lorentzen T (2005). Introduction to the characterization of residual stress by neutron diffraction, vol 14, 1st edn. CRC Press, Boca Raton, FL, pp 249–254

Schajer GS, Whitehead PS (2018) Hole-drilling method for measuring residual stress. Springer, New York

Jang J-I (2009) Estimation of residual stress by instrumented indentation: a review. J Ceram Process Res 10(3):391–400

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 7:1564–1583

Suresh S, Giannakopoulos AE (1998) A new method for estimating residual stresses by instrumented sharp indentation. Acta Mater 46(16):5755–5767

Lee Y, Kwon D (2004) Estimation of biaxial surface stress by instrumented indentation with sharp indenters. Acta Mater 52(6):1555–1563

Cheng YT, Cheng CM (2004) Scaling, dimensional analysis, and indentation measurements. Mater Sci Eng R Rep 44(4–5):91–149

Kokubo S (1932) On the change in hardness of a plate caused by bending. Sci Rep Tohoku Imperial Univ 21:256

Sines G, Carlson R (1952) Hardness measurements for determination of residual stresses. ASTM Bull 180:35–37

Carlsson S, Larsson PL (2001) On the determination of residual stress and strain fields by sharp indentation testing.: Part I: theoretical and numerical analysis. Acta Mater 49:2179–2191

Tsui TY, Oliver WC, Pharr GM (1996) Influences of stress on the measurement of mechanical properties using nanoindentation: Part I. Experimental studies in an aluminum alloy. J Mater Res 11(3):752–759

Larsson PL (2014) On the determination of biaxial residual stress fields from global indentation quantities. Tribol Lett 54(1):89–97

Underwood JH (1973) Residual-stress measurement using surface displacements around an indentation. Exp Mech 13(9):373–380

Suterio R, Albertazzi A, Amaral FK (2006) Residual stress measurement using indentation and a radial electronic speckle pattern interferometer - recent progress. J Strain Anal Eng Des 41(7):517–524

Chen J, Liu J, Sun C (2016) Residual stress measurement via digital image correlation and sharp indentation testing. Opt Eng 55(12):124102

Hwang Y, Marimuthu KP, Kim N, Lee C, Lee H (2021) Extracting plastic properties from in-plane displacement data of spherical indentation imprint. Int J Mech Sci 197:106291

Kim Jh, Choi S, Lee J et al (2019) An indentation method for evaluation of residual stress: estimation of stress-free indentation curve using stress-independent indentation parameters. J Mater Res 34:1103–1111

**ao L, Ye D, Chen C (2014) A further study on representative models for calculating the residual stress based on the instrumented indentation technique. Comput Mater Sci 82:476–482

Beghini M, Bertini L, Fontanari V (2006) Evaluation of the stress-strain curve of metallic materials by means of spherical indentation. Int J Solids Struct 43:2441–2459

Kim KH, Kim YC, Kang SK, Kim KH, Kwon DI (2010) Multiscale map** of mechanical properties by instrumented indentation test. Mater Sci Forum 654–656:2316–2321

Peng G, Xu F, Chen J, Wang H, Hu J, Zhang T (2020) Evaluation of non-equibiaxial residual stresses in metallic materials via instrumented spherical indentation. Metals 10(4):440

Ahn J, Kwon D (2001) Derivation of plastic stress–strain relationship from ball indentations: Examination of strain definition and pileup effect. J Mater Res 16(11):3170–3178

Jeon E, Park J, Kwon D (2003) Statistical analysis of experimental parameters in continuous indentation tests using taguchi method. ASME J Eng Mater Technol 125(4):406–411

Mata M, Alcala J (2004) The role of friction on sharp indentation. J Mech Phys Solids 52(1):145–165

Wang Q, Ozaki K, Ishikawa H, Nakano S, Ogiso H (2006) Indentation method to measure the residual stress induced by ion implantation. Nucl Instrum Methods Phys Res Sect B 242(1–2):88–92

Taljat B, Pharr GM (2004) Development of pile-up during spherical indentation of elastic–plastic solids. Int J Solids Struct 41(14):3891–3904

Cheng YT, Cheng CM (1998) Scaling relationships in conical indentation in elastic-plastic solids with work-hardening. MRS Online Proc Libr 522(1):139–144

ASTM E18–22 (2023) Standard test methods for rockwell hardness of metallic materials. ASTM, West Conshohocken, PA, USA

Schajer GS, To L (2023) Simulation of infinite boundaries for axisymmetric finite element models. Exp Mech 63(5):965–971

Tabor D (1951) Hardness of metals. Clarendon, Oxford, pp 41–42

Xue Z, Huang Y, Hwang K, Li M (2002) The Influence of Indenter Tip Radius on the Micro-Indentation Hardness J Eng Mater Technol 124(3):371–379

Acknowledgements

The authors thank Prof. Dongil Kwon for kindly making available an instrumented indentation system for use in this research.

Funding

The work was financially supported by the Natural Sciences and Engineering Research Council of Canada (NSERC).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

G. S. Schajer is a Fellow of SEM.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Vaidyanathan, S., Schajer, G.S. Determining Residual Stress Using Indentation and Surface Displacement Measurement. Exp Mech (2024). https://doi.org/10.1007/s11340-024-01090-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11340-024-01090-w