Abstract

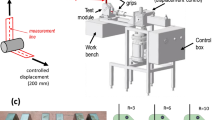

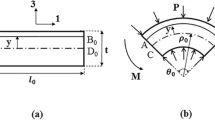

We describe an innovative design for an in-plane measurement technique that subjects thin sheet metal specimens to bidirectional loading. The goal of this measurement is to provide the critical performance data necessary to validate complex predictions of the work hardening behavior during reversed uniaxial deformation. In this approach, all of the principal forces applied to the specimen are continually measured in real-time throughout the test. This includes the lateral forces that are required to prevent out of plane displacements in the specimen that promote buckling. This additional information will, in turn, improve the accuracy of the compensation for the friction generated between the anti-bucking guides and the specimen during compression. The results from an initial series of experiments not only demonstrate that our approach is feasible, but that it generates data with the accuracy necessary to quantify the directionally-dependent changes in the yield behavior that occur when the strain path is reversed (i.e., the Bauschinger Effect).

Similar content being viewed by others

Notes

Certain commercial entities, equipment, or materials may be identified in this document in order to describe an experimental procedure or concept adequately. Such identification is not intended to imply recommendation or endorsement by the National Institute of Standards and Technology, nor is it intended to imply that the entities, materials, or equipment are necessarily the best available for the purpose.

References

Lee M-G, Kim D, Kim C, Wenner ML, Wagoner RH, Chung K (2005) Spring-back evaluation of automotive sheets based on isotropic-kinematic hardening laws and non-quadratic anisotropic yield functions: Part II: characterization of material properties. I J Plasticity 21(5):883–914. doi:10.1016/j.ijplas.2004.05.015

Cho Y-G, Kim J-Y, Cho H-H, Cha P-R, Suh D-W, Lee JK, Han HN (2012) Analysis of transformation plasticity in steel using a finite element method coupled with a phase field model. PLoS One 7(4):e35987. doi:10.1371/journal.pone.0035987

Chung K, Lee M-G, Kim D, Kim C, Wenner ML, Barlat F (2005) Spring-back evaluation of automotive sheets based on isotropic-kinematic hardening laws and non-quadratic anisotropic yield functions: Part I: theory and formulation. I J Plasticity 21(5):861–882. doi:10.1016/j.ijplas.2004.05.016

Fernandes JV, Rodrigues DM, Menezes LF, Vieira MF (1998) A modified Swift law for prestrained materials. I J Plasticity 14(6):537–550. doi:10.1016/s0749–6419(98)00027–8

Allain S, Bouaziz O (2008) Microstructure based modeling for the mechanical behavior of ferrite–pearlite steels suitable to capture isotropic and kinematic hardening. Mater Sci and Engr: A 496(1–2):329–336. doi:10.1016/j.msea.2008.06.009

Edwards EH, Washburn J, Parker ER (1953) Some Observations on The Work Hardening of Metals. Transactions of the American Institute of Mining and Metallurgical Engineers 197(11):1525–1529

Tan Z, Magnusson C, Persson B (1994) The Bauschinger effect in compression-tension of sheet metals. Mater Sci and Engr: A 183(1–2):31–38. doi:10.1016/0921–5093(94)90887–7

Yoshida F, Uemori T, Fujiwara K (2002) Elastic–plastic behavior of steel sheets under in-plane cyclic tension–compression at large strain. I J Plasticity 18(5–6):633–659. doi:10.1016/s0749–6419(01)00049–3

Kostryzhev A, Strangwood M, Davis C (2010) Bauschinger effect in Microalloyed steels: part I. Dependence on dislocation-particle interaction. Metall Mater Trans A 41(6):1399–1408. doi:10.1007/s11661-010-0196-4

Mughrabi H (1983) Dislocation wall and cell structures and long-range internal stresses in deformed metal crystals. Acta Mater 31:1367–1379

Sleeswyk AW, James MR, Plantinga DH, Maathius WST (1978) Reversible strain in cyclic plastic deformation. Acta Mater 26:1265–1271

Kassner ME, Geantil P, Levine LE (2013) Long range internal stresses in single-phase crystalline materials. I J Plasticity 45 (0):44–60. doi:10.1016/j.ijplas.2012.10.003

Swift HW (1952) Plastic instability under plane stress. J Mech Phys Solids 1(1):1–18. doi:10.1016/0022-5096(52)90002-1

Frederick CO, Armstrong PJ (2007) A mathematical representation of the multiaxial Bauschinger effect. Materials at High Temperatures 24(1):11–26

Chaboche JL (2008) A review of some plasticity and viscoplasticity constitutive theories. I J Plasticity 24(10):1642–1693. doi:10.1016/j.ijplas.2008.03.009

Hosford WF, Caddell RM (2011) Metal Forming: Mechanics and Metallurgy, 4 edn. Cambridge University Press, New York

Lee J-W, Lee M-G, Barlat F (2012) Finite element modeling using homogeneous anisotropic hardening and application to spring-back prediction. I J Plasticity 29 (0):13–41. doi:10.1016/j.ijplas.2011.07.007

Kuwabara T (2007) Advances in experiments on metal sheets and tubes in support of constitutive modeling and forming simulations. I J Plasticity 23(3):385–419. doi:10.1016/j.ijplas.2006.06.003

Boger RK, Wagoner RH, Barlat F, Lee MG, Chung K (2005) Continuous, large strain, tension/compression testing of sheet material. I J Plasticity 21(12):2319–2343. doi:10.1016/j.ijplas.2004.12.002

Dietrich L, Turski K (1978) New Methods of Studying Thin Sheets in Compression. Eng Trans 26(1):91–99

Essmann U, Mughrabi H (1979) Annihilation of Dislocations During Tensile and Cyclic Deformation and Limits of Dislocation Densities. Phil Mag A 40(2):731–756

Neumann P (1987) Dislocation Dynamics in Fatigue. Phys Scr T19B:537–543

Laird C, Buchinger L (1985) Hardening Behavior in Fatigue. Metall Trans A 16(A):2201–2214

**ao H, Chen LS (2002) Hencky's elasticity model and linear stress-strain relations in isotropic finite hyperelasticity. Acta Mech 157(1):51–60. doi:10.1007/bf01182154

Anon (1985) ASM Handbook Volume 9: Metallography and Microstructures, vol 9. ASM Handbook, 9th edn. ASM International, Metals Park, OH

Krauss G (2005) Steels- Processing. Structure and Performance, ASM International, Metals Park, OH

Anon. (2013) Abaqus, Theory and User’s Manual, Version 6.13. Dassault Systèmes Simulia Corp, Providence, RI

Olson GB (1997) Computational Design of Hierarchically Structured Materials. Science 277(5330):1237–1242. doi:10.1126/science.277.5330.1237

**ong W, Olson GB (2015) Integrated computational materials design for high-performance alloys. MRS Bull 40(12):1035–1044. doi:10.1557/mrs.2015.273

Lanzon JM, Cardew-Hall MJ, Hodgson PD (1998) Characterizing Frictional Behavior in Sheet Metal Forming. J Mater Process Technol 80(1):251–256

Bae GH, Huh H (2011) Tension/compression test of auto-body steel sheets with the variation of the pre-strain and the strain rate. Transactions on engineering Sciences 72:213–225

Acknowledgments

All of the work described herein was performed at the National Institute of Standards and Technology and was supported by internal funding from the Materials Science and Engineering Division. We would like to acknowledge D. J. Pitchure, of the NIST Mechanical Performance Group, for his helpful suggestions and assistance with the CAD modeling, and C. Amigo, D. Barry, B. Pries, and J. Kisner, of the NIST Fabrication Technology Group, for their collective expertise and advise offered during the fabrication of the numerous precision components in our apparatus.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Stoudt, M., Levine, L.E. & Ma, L. Designing a Uniaxial Tension/Compression Test for Springback Analysis in High-Strength Steel Sheets. Exp Mech 57, 155–163 (2017). https://doi.org/10.1007/s11340-016-0202-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-016-0202-x