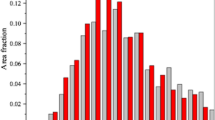

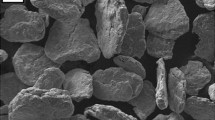

The effect of the second-phase particle precipitation on the recrystallization texture of high-strength and fine-grain interstitial-free steel was studied. It is shown experimentally that the sizes of second-phase particles increase and their number decreases with holding time and annealing temperature. The texture is mainly influenced by the size, number, and distribution of the particles. Finely dispersed second-phase particles are strongly pinned on the grain boundaries, which significantly hinders the development of {111} surface textures. It the pinning force on the grain boundary decreases, the {111) surface texture improves due to the aggregation and growth of second-phase particles with holding time. The strength of the γ-phase ({111}<112> texture) grows and reaches maximum (annealing temperature 850°C), finally declines with annealing temperature. Precipitated particles of 40–60 nm favor the development of the {111} texture component.

Similar content being viewed by others

References

L. Wang, X. F Yang, and J. X. Lu, “Development of high strength steel sheets for lightweight automobile,” Iron Steel, 41, No. 9, 1–8 (2006).

Y. Hosoya, T. Urabe, K. Tahara, et al., “Super formable steel sheet with tensile strength of 390–440 N/mm 2 ,” NKK Tech. Rev., No. 72, 1–9 (1995).

S. K. Tiwary, C. N. Jha, A. J. Khan, et al., “Development of interstitial free steel at Tata steel,” Trans Indian Inst. Met., 54, No. 3, 117–123 (2001).

J. Ma, W. M. Gao, and X. Y. Luo, “Analysis and research of second phase particles in cold rolled annealed sheet of IF steel,” Gansu Metallurgy, No. 3, 21–26 (2017).

J. C. Zhang, H. S. Di, G. W. Jiang, and C. Yu, “Effect of annealing temperature on FeTiP-type precipitate in P-Added IF high strength steel,” J. Northeastern Univ., No. 35, 1404–1410 (2014).

Y. J. Li, Research of Relationship between Cold-Rolled Process Parameters and Deep Drawing Performance of IF Steel, Hebei University of Technology, Tangshan (2002).

T. Urabe, F. Kitano, T. Fujita, et al., “State-of-art high strength steel sheet for the automotive application,” Mater. Sci. Forum, 539–543, 4369–4374 (2007).

Z. D. Wang, Y. H. Guo, D. Q. Sun, et al., “Texture comparison of an ordinary IF steel and a high-strength IF steel under ferritic rolling and high-temperature coiling,” Mater. Charact., 57, Nos. 4–5, 402–407 (2006).

I. L. Dillamore and W. T. Roberts, “Rolling textures in f.c.c. and b.c.c. metals,” Acta Metall. Mater., 12, No. 3, 281–293 (1964).

P. Jia, “Study on development and production technology of IF steel,” Gansu Metallurgy, No. 3, 39–42 (2017).

F. Y. Yu, Y. N. Wang, and Q. W. Jiang, “The research of deep drawing IF steel recrystallization {111} fiber texture’s formation mechanism,” Int. J. Mater. Sci. Technol., 16, No. 5, 30–35 (2006).

H. W. Yen, P. Y. Chen, C. Y. Huang, and J. R. Yang, “Interphase precipitation of nanometer-sized carbides in a titanium-molybdenum-bearing low-carbon steel,” Acta Mater., 59, No. 16, 6264–6274 (2011).

S. Matsuoka, K. Hasegawa, and Y. Tanaka, “Newly-developed ultra-high tensile strength steels with excellent formability and weldability,” JFE Tech. Rep., No. 10, 13–20 (2007).

T. Urabe and J. J. Jonas, “Modeling texture change during the recrystallization of an IF steel,” ISIJ Int., 34, No. 5, 435–442 (1994).

Q. W. Jiang, E. B. Zhao, J. G. Zhang, et al., “Texture, microstructure and second- phase particles in a Ti+P interstitial free (IF) steel,” Mater. Sci. Forum, 495–497, 423–428 (2005).

S. Tangen, K. Sjølstad, T. Furu, and E. Nes, “Effect of concurrent precipitation on recrystallization and evolution of the P-Texture component in a commercial Al-Mn alloy,” Metall. Mater. Trans. A, 41, No. 11, 2970–2983 (2010).

C. Y. Huang, H. W. Yen, Y. T. Pan, and J. R. Yang, “The development of nano-precipitation strengthened hot-rolled automobile steels,” Int. J. Min. Metall., 53, 45–60 (2010).

H. W. Yen, C. Y. Chen, T. Y. Wang, et al., “Orientation relationship transition of nanometre sized interphase precipitated TiC carbides in Ti bearing steel,” Mater. Sci. Tech., 26, No. 4, 421–430 (2010).

Z. C. Wang, X. J. Wang,and X. G. Zhu, “The character feature of interstitial free high strength steel,” Iron Steel, 30, No. 2, 63–68 (1995).

Z. S. Zhao, W. M. Mao, and Y. N. Yu, “The effect of Ti on the second-phase particles precipitation and mechanical properties for high strength steel,” Iron Steel, 35, No. 9, 47–51 (2000).

R. Song, D. Ponge, D. Raabe, and R. Kaspar, “Microstructure and crystallographic texture of an ultrafine grained C–Mn steel and their evolution during warm deformation and annealing,” Acta Mater., 53, No. 3, 845–858 (2005).

A. Merlini and P. A. Beck, “Study of the origin of the cube texture,” Acta Metall. Mater., 1, No. 6, 598–606 (1953).

J. Shi and X. Wang, “Comparison of precipitate behaviors in ultra-low carbon, titanium-stabilized interstitial free steel sheets under different annealing processes,” J. Mater. Eng. Perform., 8, No. 6, 641–648 (1999).

P. Ghosh, C. Ghosh, and R. K. Ray, “Precipitation in interstitial free high strength steels,” ISIJ Int., 49, No. 7, 1080–1086 (2009).

P. Ghosh, C. Ghosh, R. K. Ray, and B. Bhattacharaya, “Precipitation behavior and texture formation at different stages of processing in an interstitial free high strength steel,” Scripta Mater., 59, No. 3, 276–278 (2008).

Acknowledgments

The authors are very thankful for the financial support from the Natural Science Foundation of China (NSFC: No. 51474127 “Influence of the size effect on the deformation behavior of profile and flexible rolling at the microscale” and No. 51671100 “Preparation of composite micro drill material and micro extrusion forming mechanism”) and the State Key Laboratory of Metal Material for Marine Equipment and Application/School of Material and Metallurgy, University of Science and Technology Liaoning co-project (No. SKLMEA-USTLN 2017010).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Prochnosti, No. 1, pp. 49 – 60, January – February, 2020.

Rights and permissions

About this article

Cite this article

Zhang, H.M., Chen, R., Wang, C.S. et al. Effect of the Second-Phase Particle Precipitation on the Recrystallization Texture of High-Strength and Fine-Grain Interstitial-Free Steel. Strength Mater 52, 40–50 (2020). https://doi.org/10.1007/s11223-020-00148-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-020-00148-z