Abstract

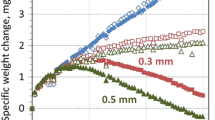

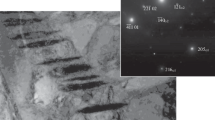

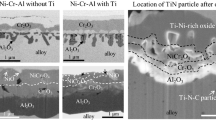

This paper examines the oxidation behavior of thin specimens of cast NiCoCrAlY alloys at 1150 \(^\circ {\rm C}\) through successive stages, from \({\rm Al}_2{\rm O}_3\) growth to complete alloy conversion to oxide. Five alloy compositions were used, with varying fractions and compositions of \(\gamma\) and \(\beta\). The time evolution of the alloy composition during \({\rm Al}_2{\rm O}_3\) growth was simulated using the DICTRA module of Thermo-Calc and calculated analytically in the approximation of flat profiles. Simulated and experimental profiles were found to be in good agreement, indicating that the phase equilibrium and mass balance were correctly reproduced in the simulations. Local variations of alloy composition were observed in thinner specimens and found to be comparable with the variations expected from the uncertainty on the initial specimen thickness. The variations observed in the time-to-\({\rm Al}_2{\rm O}_3\) failure were greater than expected on this basis, suggesting that additional sources of variability were in effect. Alumina failure was followed by the growth of a \({\rm Cr}_2{\rm O}_3\) layer at the alloy–scale interface. Similarly, Cr consumption eventually led to \({\rm Cr}_2{\rm O}_3\) failure, and Ni- and Co-containing spinel oxide formed, converting the \({\rm Cr}_2{\rm O}_3\) at the alloy–scale interface and the \({\rm Al}_2{\rm O}_3\) at the scale–gas interface. The remaining NiCo alloy was then converted to (Ni,Co)O. This sequence occurred without abrupt increase in the mass gain, due to the continued presence of the remnant \({\rm Al}_2{\rm O}_3\) layer, and to the small amount of metal left to oxidize when the (Ni,Co)O eventually broke through the scale. The evolution of the scale composition throughout the oxidation stages is discussed based on an analysis of the thermodynamic conditions at the alloy–scale interface.

Similar content being viewed by others

References

D. Young, High Temperature Oxidation and Corrosion of Metals, 2nd edn. (Elsevier, 2016).

C. Wagner, Zeitschrift Fur Elektrochemie 63, 772 (1959).

R. A. Rapp, Acta Metallurgica 9, 730 (1961).

C. Wagner, Journal of the Electrochemical Society 99, 369 (1952).

H. E. Evans, A. T. Donaldson, T. C. Gilmour, Oxidation of Metals 52, 379 (1999).

D. Texier, D. Monceau, Z. Hervier, E. Andrieu, Surface and Coatings Technology 307, 81 (2016).

W. J. Quadakkers, K. Bongartz, Materials and Corrosion 45, 232 (1994).

B. D. Bastow, D. P. Whittle, G. C. Wood, Oxidation of Metals 12, 413 (1978).

J. A. Nesbitt, Oxidation of Metals 44, 309 (1995).

T. Gheno, G. Lindwall, Oxidation of Metals 91, 243 (2019).

R. Duan, A. Jalowicka, K. Unocic, B. A. Pint, P. Huczkowski, A. Chyrkin, D. Grüner, R. Pillai, W. J. Quadakkers, Oxidation of Metals 87, 11 (2017).

R. Newton, M. J. Bennett, J. P. Wilber, J. Nicholls, D. Naumenko, G. Borchardt, A. Kolb-Telipes, B. Jonsson, A. Westerlund, V. Guttman, M. Maier, P. Beaven, Lifetime Modelling of High Temperature Corrosion Processes: IoM Communications, pp. 15–36 (2001).

K. Ishii, M. Kohno, S. Ishikawa, Materials Transactions, JIM 38, 787 (1997).

N. Hiramatsu, F. H. Stott, Oxidation of Metals 51, 479 (1999).

H. Al-Badairy, G. J. Tatlock, M. J. Bennett, Materials at High Temperatures 17, 101 (2000).

G. Strehl, D. Naumenko, H. Al-Badairy, L. M. Rodriguez Lobo, G. Borchardt, G. J. Tatlock, W. Quadakkers, Materials at High Temperatures 17, 87 (2000).

G. Tatlock, H. Al-Badairy, M. Bennett, J. Nicholls, Materials at High Temperatures 22, 467 (2005).

G. J. Tatlock, H. Al-Badairy, M. J. Bennett, R. Newton, J. R. Nicholls, A. Galerie, Materials Science and Technology 21, 893 (2005).

D. J. Young, A. Chyrkin, J. He, D. Gruener, W. J. Quadakkers, Oxidation of Metals 79, 405 (2013).

A. Chyrkin, N. Mortazavi, M. Halvarsson, D. Gruener, W. J. Quadakkers, Corrosion Science 98, 688 (2015).

P. Niranatlumpong, C. B. Ponton, H. E. Evans, Oxidation of Metals 53, 241 (2000).

H. E. Evans, M. P. Taylor, Oxidation of Metals 55, 17 (2001).

D. Texier, M. Ecochard, T. Gheno, D. Monceau, M. Salem, P. Lours, Corrosion Science 184, 109334 (2021).

J. Andersson, T. Helander, L. Höglund, P. Shi, B. Sundman, Calphad: Computer Coupling of Phase Diagrams and Thermochemistry 26, 273 (2002).

T. Gheno, B. Gleeson, Oxidation of Metals 87, 249 (2017).

T. Gheno, X. L. Liu, G. Lindwall, Z.-K. Liu, B. Gleeson, Science and Technology of Advanced Materials 16, 055001 (2015).

X. L. Liu, G. Lindwall, T. Gheno, Z.-K. Liu, Calphad 52, 125 (2016).

Materials Preparation Center, Ames Laboratory USDOE, Ames, IA (USA).

D. Texier, D. Monceau, J.-C. Salabura, R. Mainguy, E. Andrieu, Materials at high temperatures 33, 325 (2016).

N. Saunders, A. P. Miodownik, CALPHAD (Calculation of Phase Diagrams): A Comprehensive Guide. (Elsevier, 1998).

H. Lukas, S. Fries, B. Sundman, Computational Thermodynamics: The Calphad Method. (Cambridge University Press, 2007).

Thermo-Calc Software MOBNI5 Ni-alloys Mobility Database.

Thermo-Calc Software TCNI8 Ni-based Superalloys Database.

D. Naumenko, B. Gleeson, E. Wessel, L. Singheiser, W. J. Quadakkers, Metallurgical and Materials Transactions A 38, 2974 (2007).

D. J. Young, D. Naumenko, L. Niewolak, E. Wessel, L. Singheiser, W. J. Quadakkers, Materials and Corrosion-Werkstoffe Und Korrosion 61, 838 (2010).

L. Bataillou, C. Desgranges, L. Martinelli, D. Monceau, Corrosion Science 136, 148 (2018).

Physical constants of inorganic compounds, in CRC Handbook of Chemistry and Physics, ed. D.R. Lide, 89th edn. (CRC Press, Boca Raton, 2008), pp. 4–45.

T. Gheno, B. Gleeson, Oxidation of Metals 86, 385 (2016).

D. J. Young, A. Chyrkin, W. J. Quadakkers, Oxidation of Metals 77, 253 (2012).

T. J. Nijdam, W. G. Sloof, Acta Materialia 56, 4972 (2008).

M. S. A. Karunaratne, S. L. Ogden, S. D. Kenny, R. C. Thomson, Materials Science and Technology 25, 287 (2009).

M. Bensch, A. Sato, N. Warnken, E. Affeldt, R. Reed, U. Glatzel, Acta Materialia 60, 5468 (2012).

K. Yuan, R. Eriksson, R. L. Peng, X.-H. Li, S. Johansson, Y.-D. Wang, Surface and Coatings Technology 232, 204 (2013)

R. Pillai, W. G. Sloof, A. Chyrkin, L. Singheiser, W. J. Quadakkers, Materials at High Temperatures 32, 57 (2015).

R. Pillai, S. S. Raiman, B. A. Pint, Journal of Nuclear Materials 546, 152755 (2021).

J. Philibert, Atom movements—Diffusion and mass transport in solids (Les Editions de Physique, 1991).

P. Saltykov, O. Fabrichnaya, J. Golczewski, F. Aldinger, Journal of Alloys and Compounds 381, 99 (2004).

E. Schmucker, C. Petitjean, L. Martinelli, P.-J. Panteix, S. Ben Lagha, M. Vilasi, Corrosion Science 111, 474 (2016).

P. Kofstad, High Temperature Corrosion (Elsevier, 1988).

L. Latu-Romain, Y. Parsa, S. Mathieu, M. Vilasi, M. Ollivier, A. Galerie, Y. Wouters, Oxidation of Metals 86, 497 (2016).

L. Latu-Romain, S. Mathieu, M. Vilasi, G. Renou, S. Coindeau, A. Galerie, Y. Wouters, Oxidation of Metals 88, 481 (2017).

Acknowledgements

The authors thank Brian Gleeson (University of Pittsburgh) for providing the cast alloys. This work was supported in part by the Agence Nationale de la Recherche (France), grant numbers ANR-18-CE08-0003 and ANR-19-CE08-0004.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gheno, T., Rio, C., Ecochard, M. et al. Alumina Failure and Post-failure Oxidation in the NiCoCrAlY Alloy System at High Temperature. Oxid Met 96, 487–517 (2021). https://doi.org/10.1007/s11085-021-10060-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-021-10060-9