Abstract

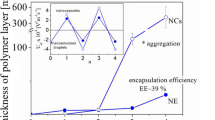

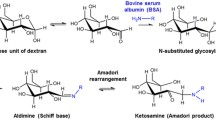

The Ugi four-component condensation in diluted liposomal suspensions was used to prepare pectin-based submicron capsules. A set of isocyanides and aldehydes was used to optimize the synthesis of capsule shells. Modified sugar beet pectin was selected as a natural polymer with pronounced surface activity to create a capsule shell. At first, liposomal composition was optimized in order to select suitable conditions for capsule formation. Then, the wide set of capsules constructed on modified sugar beet pectin scaffold has been synthesized. The choice was determined by level of substitution degree and possible chemical diversity of the modified surface. Detailed characterization of products has been performed for polysaccharide particles with liposomal core prepared with various processing parameters (concentration, cross-linking components, the density of linkage). The chemical structure, average size, polydispersity index, morphology, stability, and cytotoxicity of obtained particles have been investigated in dependence on the shell content. The obtained submicrometer cross-linked capsules (220–240 nm) with controlled colloidal properties showed high stability and low toxicity. Thus, the proposed carriers have a great potential as sustained drug delivery systems for different administration routes.

Graphical abstract

Similar content being viewed by others

References

Jiang B, Hu L, Gao C, Shen J (2006) Crosslinked polysaccharide nanocapsules: preparation and drug release properties. Acta Biomater 2(1):9–18. https://doi.org/10.1016/j.actbio.2005.08.006

Liu Y, Yang J, Zhao Z, Li J, Zhang R, Yao F (2012) Formation and characterization of natural polysaccharide hollow nanocapsules via template layer-by-layer self-assembly. J Colloid Interface Sci 379(1):130–140. https://doi.org/10.1016/j.jcis.2012.04.058

Luo GF, Xu XD, Zhang J, Yang J, Gong YH, Lei Q, Zhang XZ (2012) Encapsulation of an adamantane-doxorubicin prodrug in pH-responsive polysaccharide capsules for controlled release. ACS Appl Mater Interfaces 4(10):5317–5324. https://doi.org/10.1021/am301258a

Saha S, Pal A, Kundu S, Basu S, Pal T (2009) Photochemical green synthesis of calcium-alginate-stabilized Ag and Au nanoparticles and their catalytic application to 4-nitrophenol reduction. Langmuir 26(4):2885–2893. https://doi.org/10.1021/la902950x

Pan L, Yu G, Zhai D, Lee HR, Zhao W, Liu N, Wang H, Tee BC-K, Shi Y, Cui Y, Bao Z (2012) Hierarchical nanostructured conducting polymer hydrogel with high electrochemical activity. Proc Natl Acad Sci USA 109(24):9287–9292. https://doi.org/10.1073/pnas.1202636109

Song R-B, Yan K, Lin Z-Q, Loo JSC, Pan L-J, Zhang Q, Zhang J-R, Zhu J-J (2016) Inkjet-printed porous polyaniline gel as an efficient anode for microbial fuel cells. J Mater Chem A 4:14555–14559. https://doi.org/10.1039/c6ta05770e

Hirsjärvi S, Dufort S, Bastiat G, Saulnier P, Passirani C, Coll JL, Benoît JP (2013) Surface modification of lipid nanocapsules with polysaccharides: from physicochemical characteristics to in vivo aspects. Acta Biomater 9(5):6686–6693. https://doi.org/10.1016/j.actbio.2013.01.038

Meier W (2000) Polymer nanocapsules. Chem Soc Rev 29(5):295–303. https://doi.org/10.1039/A809106D

Liu Z, Jiao Y, Wang Y, Zhou C, Zhang Z (2008) Polysaccharides-based nanoparticles as drug delivery systems. Adv Drug Deliv Rev 60(15):1650–1662. https://doi.org/10.1016/j.addr.2008.09.001

Yang J, Han S, Zheng H, Dong H, Liu J (2015) Preparation and application of micro/nanoparticles based on natural polysaccharides. Carbohydr Polym 123:53–66. https://doi.org/10.1016/j.carbpol.2015.01.029

Mizrahy S, Peer D (2012) Polysaccharides as building blocks for nanotherapeutics. Chem Soc Rev 41(7):2623–2640. https://doi.org/10.1039/c1cs15239d

Fukui Y (2017) Preparation of liponanocapsules via construction of bio-derived capsule wall on a liposomal template. Kobunshi Ronbunshu 74(5):396–409. https://doi.org/10.1295/koron.2017-0023

Campani V, Giarra S, De Rosa G (2018) Lipid-based core-shell nanoparticles: evolution and potentialities in drug delivery. OpenNano 3:5–17. https://doi.org/10.1016/j.onano.2017.12.001

Volodkin D, Arntz Y, Schaaf P, Moehwald H, Voegel JC, Ball V (2007) Composite multilayered biocompatible polyelectrolyte films with intact liposomes: stability and temperature triggered dye release. Soft Matter 4(1):122–130. https://doi.org/10.1039/b713563g

Netsomboon K, Bernkop-Schnürch A (2016) Mucoadhesive vs. mucopenetrating particulate drug delivery. Eur J Pharm Biopharm 98:76–89. https://doi.org/10.1016/j.ejpb.2015.11.003

Fracasso F, Perussello CA, Carpiné D, de Oliveira Petkowicz CL, Haminiuk CWI (2018) Chemical modification of citrus pectin: structural, physical and rheologial implications. Int J Biol Macromol 109:784–792. https://doi.org/10.1016/j.ijbiomac.2017.11.060

Karim N, Shishir MRI, Chen W (2020) Surface decoration of neohesperidin-loaded nanoliposome using chitosan and pectin for improving stability and controlled release. Int J Biol Macromol 164:2903–2914. https://doi.org/10.1016/j.ijbiomac.2020.08.174

Bertolino V, Cavallaro G, Milioto S, Lazzara G (2020) Polysaccharides/Halloysite nanotubes for smart bionanocomposite materials. Carbohydr Polym 245:116502. https://doi.org/10.1016/j.carbpol.2020.116502

Makaremi M, Yousefi H, Cavallaro G, Lazzara G, Goh CBS, Lee SM, Pasbakhsh P (2019) Safely dissolvable and healable active packaging films based on alginate and pectin. Polymers 11(10):1594. https://doi.org/10.3390/polym11101594

Yan X, Chai L, Fleury E, Ganachaud F, Bernard J (2021) ‘Sweet as a Nut’: production and Use of Nanocapsules made of Glycopolymer or Polysaccharide shell. Prog Polym Sci. https://doi.org/10.1016/j.progpolymsci.2021.101429

Noh J, Kim J, Kim JS, Chung YS, Chang ST, Park J (2018) Microencapsulation by pectin for multi-components carriers bearing both hydrophobic and hydrophilic active agents. Carbohydr Polym 182:172–179. https://doi.org/10.1016/j.carbpol.2017.11.026

Li Y, Zhao H, Duan L-R, Li H, Yang Q, Tu H-H, Cao W, Wang S-W (2014) Preparation, characterization and evaluation of bufalin liposomes coated with citrus pectin. Colloids Surf A 444:54–62. https://doi.org/10.1016/j.colsurfa.2013.12.006

Haghighi M, Yarmand MS, Emam-Djomeh Z, McClements DJ, Saboury AA, Rafiee-Tehrani M (2018) Design and fabrication of pectin-coated nanoliposomal delivery systems for a bioactive polyphenolic: phloridzin. Int J Biol Macromol 112:626–637. https://doi.org/10.1016/j.ijbiomac.2018.01.108

Yapo BM, Robert C, Etienne I, Wathelet B, Paquot M (2007) Effect of extraction conditions on the yield, purity and surface properties of sugar beet pulp pectin extracts. Food Chem 100:1356–1364. https://doi.org/10.1016/j.foodchem.2005.12.012

Stephen AM, Phillips GO, Williams PA (eds) (2006) Food Polysaccharides and Their Applications. CRC Press, Boca Raton, pp 287–340

Lopes NA, Pinilla CMB, Brandelli A (2017) Pectin and polygalacturonic acid-coated liposomes as novel delivery system for nisin: preparation, characterization and release behavior. Food Hydrocoll 70:1–7. https://doi.org/10.1016/j.foodhyd.2017.03.016

Siew CK, Williams PA (2008) Role of protein and ferulic acid in the emulsification properties of sugar beet pectin. J Agric Food Chem 56:4164–4171. https://doi.org/10.1021/jf073358o

Thirawong N, Kennedy RA, Sriamornsak P (2008) Viscometric study of pectin—mucin interaction and its mucoadhesive bond strength. Carbohydr Polym 71(2):170–179. https://doi.org/10.1016/j.carbpol.2007.05.026

Hagesaether E, Sande SA (2007) In vitro measurements of mucoadhesive properties of six types of pectin. Drug Dev Ind Pharm 33(4):417–425. https://doi.org/10.1080/03639040600920630

Sharma R, Ahuja M, Kaur H (2012) Thiolated pectin nanoparticles: preparation, characterization and ex vivo corneal permeation study. Carbohydr Polym 87(2):1606–1610. https://doi.org/10.1016/j.carbpol.2011.09.065

Zarganes-Tzitzikas T, Chandgude A, Dömling A (2015) Multicomponent reactions, union of MCRs and beyond. Chem Rec 15:981–996. https://doi.org/10.1002/tcr.201500201

Mironov MA, Ivantsova MN, Mokrushin VS (2003) Ugi reaction in aqueous solutions: a simple protocol for libraries production. Mol Divers 6:193–197. https://doi.org/10.1023/b:modi.0000006758.61294.57

Pirrung MC, Sarma KD (2004) Multi-component reactions are accelerated in water. J Am Chem Soc 126:444–445. https://doi.org/10.1021/ja038583a.s001

Shapiro N, Vigalok A (2008) Highly efficient organic reactions “on water”, “in water”, and both. Angew Chem Int Ed 47(15):2849–2852. https://doi.org/10.1002/anie.200705347

Medeiros GA, da Silva WA, Bataglion GA, Ferreira DAC, de Oliveira HCB, Eberlin MN, Neto BAD (2014) Probing the mechanism of the Ugi four-component reaction with charge-tagged reagents by ESI-MS(/MS). Chem Commun 50:338–340. https://doi.org/10.1039/c3cc47156j

Pirrung MC, Sarma KD, Wang J (2008) Hydrophobicity and mixing effects on select heterogeneous, water-accelerated synthetic reactions. J Org Chem 73(22):8723–8730. https://doi.org/10.1021/jo801134r

Yang B, Zhao Y, Fu C, Zhu C, Zhang Y, Wang S, Weia Y, Tao L (2014) Introducing the Ugi reaction into polymer chemistry as a green click reaction to prepare middle-functional block copolymers. Polym Chem 5:2704–2708. https://doi.org/10.1039/c4py00001c

Bu H, Kjøniksen A-L, Knudsen KD, Nyström B (2004) Rheological and structural properties of aqueous alginate during gelation via the Ugi multicomponent condensation reaction. Biomacromol 5(4):1470–1479. https://doi.org/10.1021/bm049947+

Werner B, Bu H, Kjøniksen AL, Sande SA, Nyström B (2006) Characterization of gelation of aqueous pectin via the Ugi multicomponent condensation reaction. Polym Bull 56(6):579–589. https://doi.org/10.1007/s00289-006-0522-6

Nazeri MT, Javanbakht S, Nabi M, Shaabani A (2022) Copper phthalocyanine-conjugated pectin via the Ugi four-component reaction: an efficient catalyst for CO2 fixation. Carbohydr Polym 283:119144. https://doi.org/10.1016/j.carbpol.2022.119144

**ngnan LI, Franke AA (2011) Improved LC−MS method for the determination of fatty acids in red blood cells by LC−orbitrap MS. Anal Chem 83:3192–3198. https://doi.org/10.1021/ac103093w

Ugi I, Fetzer U, Eholzer U, Knupfer H, Offermann K (1965) Isonitrile syntheses. Angew Chem 4:472–484. https://doi.org/10.1002/anie.196504721

Nguyen S, Alund SJ, Hiorth M, Kjoniksen A-L, Smistad G (2011) Studies on pectin coating of liposomes for drug delivery. Colloids Surf B 88:664–673. https://doi.org/10.1016/j.colsurfb.2011.07.058

Mironov MA, Shulepov ID, Ponomarev VS, Bakulev VA (2013) Synthesis of polyampholyte microgels from colloidal salts of pectinic acid and their application as pH-responsive emulsifiers. Colloid Polym Sci 291:1683–1691. https://doi.org/10.1007/s00396-013-2903-3

Kozhikhova KV, Ivantsova MN, Tokareva MI, Shulepov ID, Tretiyakov AV, Shaidarov LV, Rusinov VL, Mironov MA (2018) Preparation of chitosan-coated liposomes as a novel carrier system for the antiviral drug Triazavirin. Pharm Dev Technol 23(4):334–342. https://doi.org/10.1080/10837450.2016.1242624

Palomba R, di Francesco M, di Francesco V, Piccardi F, Catelani T, Ferreira M, Decuzzi P (2021) Boosting nanomedicine performance by conditioning macrophages with methyl palmitate nanoparticles. Mater Horiz 8(10):2726–2741. https://doi.org/10.1039/d1mh00937k

Mironov MA, Lvantsova MN, Tokareva MI, Mokrushin VS (2007) Novel synthesis of dihydrothiophene-2,5-diimine derivatives by the three-component reaction of isocyanides with enamines and arylisothiocyanates. Heterocycles 73:567–579. https://doi.org/10.3987/COM-07-S(U)33

Gromer A, Penfold R, Gunning AP, Kirby AR, Morris VJ (2010) Molecular basis for the emulsifying properties of sugar beet pectin studied by atomic force microscopy and force spectroscopy. Soft Matter 6:3957–3969. https://doi.org/10.1039/c0sm00089b

Acknowledgements

The authors thank Russian Science Foundation for financial support Grant 20-66-47017

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Alqubelat, R.S., Obiedallah, M.M., Minin, A.S. et al. Application of the Ugi reaction for preparation of submicron capsules based on sugar beet pectin. Mol Divers 27, 1957–1969 (2023). https://doi.org/10.1007/s11030-022-10525-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11030-022-10525-2