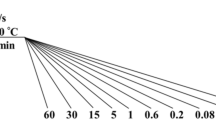

The microstructure and mechanical properties of engineering steels with high supercooled austenite stability after cooling at different rates from the austenitizing temperature are studied. Thermokinetic diagrams are plotted for supercooled austenite transformation and temperature-time intervals are determined for structural component formation during continuous cooling. In order to evaluate mechanical properties trajectories and cooling rates are established by experiment for specimens in various media, i.e., oil, still air, and a special container filled with cast iron shavings. It is shown that when the experimental cooling path is superimposed on a thermokinetic curve it is necessary to consider instantaneous cooling rates in different temperature ranges. The effect of cooling intensity on mechanical properties of steels of different composition is established quantitatively. It is found that the impact strength of steels of different alloy systems depends in different ways on cooling rate.

Similar content being viewed by others

References

S. Šolić, B. Podgornik, and V. Leskovšek, “The occurrence of quenching cracks in high-carbon tool steel depending on the austenitizing temperature,” Eng. Failure Analysis, 92, 140–148 (2018); https://doi.org/10.1016/j.engfailanal.2018.05.008.

N. I. Kobasko, “The development of quench cracks in steel,” Metal Science and Heat Treatment, 12, No. 11, 900–901 (1970); https://doi.org/10.1007/BF00653381.

E. H. Hwang, J. S. Park, S. O. Kim, H. G. Seong, and S. J. Kim, “Study on the controlling factors for the quenching crack sensitivity of ultra-strong automotive steel,” J. Mater. Sci., 55. 3605–3617 (2020); https://doi.org/10.1007/s10853-019-04177-1.

M. V. Maisuradze, Yu. V. Yudin, and D. I. Lebedev, “Thermal strengthening of large parts made from high-strength sparingly doped steel in air,” Steel in Translation, 50, No. 5, 61–66 (2020); https://doi.org/10.3103/S0967091220050083.

M. V. Maisuradze, M. A. Ryzhkov, and D. I. Lebedev, “Microstructure and mechanical properties of martensitic high strength engineering steel,” Metallurgist, 64, No. 7–8, 640–651 (2020); https://doi.org/10.1007/s11015-020-01040-6.

L. M. Kleiner, A. A. Shatsov, and D. M. Larinin, “Low-carbon martensitic steels. Alloying and properties,” Metal Science and Heat Treatment, 52, No. 11–12, 540–544 (2011); https://doi.org/10.1007/s11041-011-9316-z.

Yu. N. Simonov, O. D. Panov, M. Yu. Simonov, V. P. Vylezhnev, and A. S. Ivanov, “Principles of design of the chemical composition of steels for forming a structure of lower carbide-free bainite under delayed cooling,” Metal Science and Heat Treatment, 57, No. 7–8, 386–394 (2015); https://doi.org/10.1007/s11041-015-9894-2.

A. N. Yurchenko, Yu. N. Simonov, D. O. Panov, and A. I. Zhitenev, “Transformations, structure and properties of steel 22Kh2G2S2MF under continuous cooling,” Metal Science and Heat Treatment, 61, No. 9–10, 617–621 (2019); https://doi.org/10.1007/s11041-02000469-5.

J. Yin, M. Hillert, and A. Borgenstam, “Morphology of upper and lower bainite with 0.7 mass pct. C,” Metallurgical and Materials Transactions A, 48, 4006–4024 (2017); https://doi.org/10.1007/s11661-017-4208-5.

O. Hajizad, A. Kumar, Z. Li, R. H. Petrov, J. Sietsma, and R. Dollevoet, “Influence of microstructure on mechanical properties of bainitic steels in railway applications,” Metals, 9, No. 7, 778 (2019); https://doi.org/10.3390/met9070778.

H. K. D. H. Bhadeshia, Bainite in Steels. Theory and Practice, Maney Publishing, Leeds, UK (2015)

M. V. Maisuradze and M. A. Ryzhkov, “Microstructure and mechanical properties of the heat treated HY-TUF steel,” Materials Science Forum, 989, 324–328 (2020); https://doi.org/10.4028/www.scientific.net/MSF.989.324.

M. V. Maisuradze, Yu. V. Yudin, and A. A. Kuklina, “Increase in impact strength during bainite structure formation in HYTUF high-strength steel,” Metallurgist, 63, No. 7–8, 849–858 (2019); https://doi.org/10.1007/s11015-019-00899-4.

M. V. Maisuradze, M. A. Ryzhkov, E. V. Antakov, N. A. Popov, and P. A. Proskuryakov, “Special features of transformations of supercooled austenite in modern structural steels,” Metal Science and Heat Treatment, 62, No. 7–8, 448– 456 (2020); https://doi.org/10.1007/s11041-020-00583-4.

H. K. D. H. Bhadeshia and R. Honeycombe, Steels: Microstructure and Properties, Butterworth-Heinemann, UK (2017).

L. E. Popova and A. A. Popov, Transformation Diagram for Austenite in Steels and β-Solution in Titanium Alloys. Reference [in Russian], Metallurgiya, Moscow (1991).

M. V. Maisuradze, M. A. Ryzhkov, and Yu. V. Yudin, “Rapid evaluation of the cooling capacity of quenching media,” Metal Science and Heat Treatment, 57, No. 7–8, 515–518 (2015); https://doi.org/10.1007/s11041-015-9914-2.

ASTM D6200-01. Standard Test Method for Determination of Cooling Characteristics of Quench Oils by Cooling Curve Analysis, West Conshohocken: ASTM International (2017).

G. E., Totten, G. M. Webster, H. M. Tens, and B. Liscic, “Standards for cooling curve analysis of quenchants,” Heat Treatment of Metals, No. 4, 92–94 (1997).

P. C. Angelo and B. Ravisankar, Introduction to Steels. Processing, Properties, and Applications, CRC Press, Boca Raton (2019).

Acknowledgement

Research was conducted due to a grant of the Russian scientific fund No. 22-29-000106.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 66, No. 8, pp. 27–36, August, 2022. Russian DOI https://doi.org/10.52351/00260827_2022_08_27.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Maisuradze, M.V., Kuklina, A.A., Ryzhkov, M.A. et al. Effect of Cooling Rate during Heat Treatment on Martensitic-Bainitic Class Alloy Steel Microstructure and Properties. Metallurgist 66, 895–908 (2022). https://doi.org/10.1007/s11015-022-01402-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-022-01402-2