Abstract

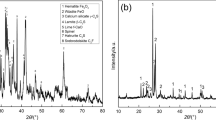

Morocco has made a concerted effort in previous years to produce renewable energy to meet market demand while protecting the environment and opening the route for circular economy. By-product from steel and iron industries in Morocco that employ electric arc furnace to produce steel is the focus of the present paper. It aims to study the possibility of using by-product “Electric Arc Furnace Slag” issued from Moroccan steel and iron industry as high-temperature sensible thermal energy storage material for the benefit of the same industry. In first, a fully characterization of the selected by-product has been performed. As a result, the filler material showed great thermophysical properties in terms of densities, thermal capacity, thermal diffusivity, and thermal conductivity. The bulk and skeletal densities are of around 3477.64 and 3913.9 kg m−3, respectively. The thermal capacity ranges between 0.3 and 0.85 kJ kg−1 K−1 for as-received by-product and from 0.6 to 0.9 kJ kg−1 K−1 for the by-product after thermal cycling. Its crystallographic structure and morphology remain similar to the one of EAF-slag studied in open literature. Thereafter, the material stability and suitability for high-temperature (up to 700 °C) thermal energy storage have been highlighted. The characteristics of EAF-slag after thermal cycling and isothermal study were compared to those of raw EAF-slag. Accordingly, the filler material is stable and able to store thermal energy at high temperatures. Equally important, thermal cycling impacts positively the filler material. Thanks to the oxidation to magnetite, the energy density of EAF-slag increases. More importantly, the material becomes more stable by exhibiting less than 1% of mass loss. Yet, few cracks were observed inside the cycled material. The investigation revealed that the fast-heating rate (superior to 5 °C min−1) is the main responsible. As a result, the authors recommend a slow heating rate especially for the first heating cycles of this by-product (around 2 °C min−1).

Similar content being viewed by others

Abbreviations

- CSP :

-

Concentrated solar power

- TES:

-

Thermal energy storage

- TESM:

-

Thermal energy storage material

- EAF :

-

Electric arc furnace

- WHR :

-

Waste heat recovery

- CAES :

-

Compressed air energy storage

- ACAES :

-

Adiabatic compressed air energy storage

- TGA:

-

Thermogravimetric analysis

- DSC:

-

Differential scanning calorimetry

- LFA:

-

Laser flash apparatus

- XRD:

-

X-ray diffraction

- XRF:

-

X-ray fluorescence

- SEM:

-

Scanning electron microscopy

- BSED:

-

Backscattered electron detector

- EDX:

-

Energy-dispersive X-ray spectroscopy

- RT:

-

Room temperature

- α:

-

TESM thermal diffusivity, m2 s-1

- \({C}_{\text{p,s}}\) :

-

TESM heat capacity, kJ kg-1 K-1

- \({d}_{{\text{bulk}}}\) :

-

Bulk density, kg m−3

- \(\lambda\) :

-

TESM thermal conductivity, W m-1 K-1

- \(\rho\) :

-

TESM density, kg m−3

References

Ortega-Fernández I, Rodríguez-Aseguinolaza J. Thermal energy storage for waste heat recovery in the steelworks: The case study of the REslag project. Appl Energy. 2019;237(2018):708–19. https://doi.org/10.1016/j.apenergy.2019.01.007.

Gutierrez A, et al. Advances in the valorization of waste and by-product materials as thermal energy storage (TES) materials. Sustain Energy Rev. 2016;59:763–83. https://doi.org/10.1016/j.rser.2015.12.071.

Zhang Q, Zhao X, Lu H, Ni T, Li Y. Waste energy recovery and energy efficiency improvement in China’s iron and steel industry. Appl Energy. 2017;191:502–20. https://doi.org/10.1016/j.apenergy.2017.01.072.

Brueckner S, Miró L, Cabeza LF, Pehnt M, Laevemann E. Methods to estimate the industrial waste heat potential of regions-a categorization and literature review. Renew Sustain Energy Rev. 2014;38:164–71. https://doi.org/10.1016/j.rser.2014.04.078.

Papapetrou M, Kosmadakis G, Cipollina A, La Commare U, Micale G. Industrial waste heat: estimation of the technically available resource in the EU per industrial sector, temperature level and country. Appl Therm Eng. 2018;138(2017):207–16. https://doi.org/10.1016/j.applthermaleng.2018.04.043.

Santangelo N, Tomadin L, Bertolissio A. CHR®-clean heat recovery from EAF hot fumes into electric energy, with consequent fuel saving and reduction of greenhouse gas emission. AISTech-Iron Steel Technol Conf Proc. 2015;3:3556–64.

Cavaliere P. Electric arc furnace: most efficient technologies for greenhouse emissions abatement. Cham: Springer; 2019.

Sonasid LEDGDE L ’ énergie au cœur des enjeux de demain Royaume. https://www.asm-maroc.ma/wp-content/uploads/2019/12/ASM-LDA-5.pdf

Some key insights on the Moroccan steel market with a focus on flat steel segment, no. December, pp. 4–7, 2017. https://www.oecd.org/industry/ind/steel-market-developments-Q4-2023.pdf

Brückner S, Liu S, Miró L, Radspieler M, Cabeza LF, Lävemann E. Industrial waste heat recovery technologies: an economic analysis of heat transformation technologies. Appl Energy. 2015;151:157–67. https://doi.org/10.1016/j.apenergy.2015.01.147.

Jouhara H, Khordehgah N, Almahmoud S, Delpech B, Chauhan A, Tassou SA. Waste heat recovery technologies and applications. Therm Sci Eng Prog. 2018;6(April):268–89. https://doi.org/10.1016/j.tsep.2018.04.017.

Fleischanderl A, Steinparzer T, Trunner P. Waste heat recovery for EAF-innovative concepts and industrial implementation. Iron Steel Technol. 2018;15(1):56–62.

Bern C SolAir-3 Innovative solar collectors for efficient and cost-effective solar thermal power generation–3, 2017

Maruoka N, Sato K, Yagi JI, Akiyama T. Development of PCM for recovering high temperature waste heat and utilization for producing hydrogen by reforming reaction of methane. ISIJ Int. 2002;42(2):215–9. https://doi.org/10.2355/isi**ternational.42.215.

Grosu Y, et al. Natural and by-product materials for thermocline-based thermal energy storage system at CSP plant: Structural and thermophysical properties. Appl Therm Eng. 2018;136(March):185–93. https://doi.org/10.1016/j.applthermaleng.2018.02.087.

Geissbühler L, et al. Pilot-scale demonstration of advanced adiabatic compressed air energy storage, part 1: plant description and tests with sensible thermal-energy storage. J Energy Storage. 2018;17:129–39. https://doi.org/10.1016/j.est.2018.02.004.

Becattini V, Geissbühler L, Zanganeh G, Haselbacher A, Steinfeld A. Pilot-scale demonstration of advanced adiabatic compressed air energy storage, part 2: tests with combined sensible/latent thermal-energy storage. J Energy Storage. 2018;17:140–52. https://doi.org/10.1016/j.est.2018.02.003.

Yildirim IZ, Prezzi M. Chemical, mineralogical, and morphological properties of steel slag. Adv Civ Eng. 2011;2011:1–13. https://doi.org/10.1155/2011/463638.

Tsakiridis PE, Papadimitriou GD, Tsivilis S, Koroneos C. Utilization of steel slag for Portland cement clinker production Utilization of steel slag for Portland cement clinker production. J Hazard Mater. 2008. https://doi.org/10.1016/j.jhazmat.2007.07.093.

Manso JM, Polanco JA, Losan M, Gonza JJ. Durability of concrete made with EAF slag as aggregate. Cem Concr Compos. 2006;28:528–34. https://doi.org/10.1016/j.cemconcomp.2006.02.008.

Ortega I, Rodríguez-Aseguinolaza J, Gil A, Faik A, D’Aguanno B Es2014-6369 Compatibility of steel slags with the most common heat, In: Proceedings of the ASME 2014 8th International Conference on Energy Sustainability, pp. 1–6, 2014.

Gil A, Calvet N, Risueño E Characterization of a by-product from steel industry applied to thermal energy storage in Concentrated Solar Power Reversible intrusion of non-wetting liquids into nanopores for energy applications View project, no. February 2015, pp. 1–9, 2014. Available: https://www.researchgate.net/publication/262764649.

Calvet N, Dejean G, Unamunzaga L, Py X Es2013-18333, Waste From Metallurgic Industry: A Sustainable High-Temperature Thermal Energy Storage Material for Concentrated Solar Power, pp. 1–6, 2016.

Shi C. Steel Slag — Its Production, Processing, Characteristics, and Cementitious Properties. J Mater Civ Eng. 2004;16:230–6.

Giencke J. Introduction to EVA. Billerica: Bruker Coop; 2007. p. 1–31.

The HighScore suite From phase identification to Rietveld analysis The HighScore suite The most comprehensive powder diffraction software. https://www.cambridge.org/core/journals/powder-diffraction/article/highscoresuite/C5F7C0DD3DA96EA5E0CFF1A0C9C87DF3

Yurramendi L, Caballero S, Río C, Pasealekua M, Sebastián S Reactivos para el secuestro de CO2, pp. 6–14, 2011.

Sotolongo R, Dorrego F, Herrero E. Characteristics of the slags produced in the fusion of scrap steel by electric arc furnace. Cem Concr Res. 2000;30:517–9.

Waples DW, Waples JS. A review and evaluation of specific heat capacities of rocks, minerals, and subsurface fluids. Part 2: Fluids and porous rocks. Nat Resour Res. 2004;13(2):123–30. https://doi.org/10.1023/B:NARR.0000032648.15016.49.

Fernández IO High temperature packed bed thermal energy storage systems based on low cost materials, 2017. (“TESIS_Ortega_Fernández_Iñigo - Estudios de Posgrado - UPV/EHU”)

Wang Y, Wang Y, Li H, Zhou J, Cen K. Solar energy materials and solar cells thermal properties and friction behaviors of slag as energy storage material in concentrate solar power plants. Sol Energy Mater Sol Cells. 2018;182(March):21–9. https://doi.org/10.1016/j.solmat.2018.03.020.

Ortega-Fernández I, Rodríguez-Aseguinolaza J. Thermal energy storage for waste heat recovery in the steelworks: The case study of the REslag project. Appl Energy. 2019;237(January):708–19. https://doi.org/10.1016/j.apenergy.2019.01.007.

Calvet N, Gil A, Rodríguez-aseguinolaza J, Faik A, Aguanno BD. Thermophysical characterization of a by-product from the steel industry to be used as a sustainable and low-cost thermal energy storage material. Energy. 2015;89:601–9. https://doi.org/10.1016/j.energy.2015.05.153.

Wang Y, Li H, Zhou J, Cen K. Thermal properties and friction behaviors of slag as energy storage material in concentrate solar power plants. Sol Energy Mater Sol Cells. 2018;182(March):21–9. https://doi.org/10.1016/j.solmat.2018.03.020.

Baba YF, Al Mers A, Ajdad H, Bouatem A Magnetite versus quartzite: Potential candidates for thermocline energy storage, In: Proceedings of 2018 6th International Renewable and Sustainable Energy Conference. IRSEC 2018, Jul. 2018, doi: https://doi.org/10.1109/IRSEC.2018.8702941.

Slimani H, et al. Characterization EAF Slag under thermal cycling as sensible thermal energy storage material, In: Proceedings of the 2021 9th International Renewable and Sustainable Energy Conference IRSEC 2021, pp. 1–6, 2021, https://doi.org/10.1109/IRSEC53969.2021.9741176.

Author information

Authors and Affiliations

Contributions

Hmida Slimani contributed to material preparation, characterization, investigation, visualization, writing—original draft, and writing—review and editing. Yousra Filali Baba contributed to conceptualization, methodology, material preparation, characterization, investigation, visualization, writing—original draft, and writing—review and editing. Abdechafik El Harrak contributed to material preparation and characterization. Fayrouz El Hamdani performed supervision. Hicham Bouzekri performed supervision. Abdessamad Faik contributed to resources, conceptualization, methodology, and writing—review and editing.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Slimani, H., Filali Baba, Y., Elharrak, A. et al. Extensive experimental characterization of Moroccan steel and iron industry by-product for high-temperature thermal energy storage. J Therm Anal Calorim 149, 5141–5152 (2024). https://doi.org/10.1007/s10973-024-13197-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-024-13197-2