Abstract

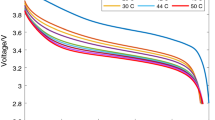

The present study aims to investigate thermal runaway induced by dynamic overcharge of lithium-ion batteries (LIBs) with Lix(Ni0.3Co0.3Mn0.2)O2 cathode under different environmental conditions. LIBs were overcharged with different charging ratios to thermal runaway in the ambient and adiabatic environment. The battery is more susceptible to thermal runaway in an adiabatic environment. The time \(T_{0}\) (apparent exothermic onset temperature) of the battery in an adiabatic environment was 160 s, 260 s, and 500 s shorter than that in the ambient environment. When \(T_{0}\) is detected, batteries need to be cooled within 14 min to prevent thermal runaway. Due to over-potential, the battery voltage will drop in the next stage after reaching the highest point. The inflection point voltage of the battery during overcharging is due to the deposition of metallic lithium in the anode graphite, which causes a significant potential shift of the anode. In the overcharging process, when the battery reaches the inflection point voltage, it must be terminated within 5 min and take measures to prevent thermal runaway. These results can render supports for understanding the overcharge mechanism and battery management system.

Similar content being viewed by others

References

Nishi Y. Lithium ion secondary batteries; past 10 years and the future. J Power Sources. 2001;100(1):101–6.

Chen M, Bai F, Lin S, Song W, Li Y, Feng Z. Performance and safety protection of internal short circuit in lithium-ion battery based on a multilayer electro-thermal coupling model. Appl Therm Eng. 2019;146:775–84.

Feng X, Ouyang M, Liu X, Lu L, **a Y, He X. Thermal runaway mechanism of lithium ion battery for electric vehicles: a review. Energy Storage Mater. 2017;10:246–67.

Lopez CF, Jeevarajan JA, Mukherjee PP. Experimental analysis of thermal runaway and propagation in lithium-ion battery modules. J Electrochem Soc. 2015;162:A1905–15.

Dong S, Feng X, Lu L, Li J, Ouyang M. Comparison of the overcharge behaviors of lithium-ion batteries under different test conditions. J Therm Anal Calorim. 2019;158:4921–7.

Spotnitz R, Franklin J. Abuse behavior of high-power, lithium-ion cells. J Power Sources. 2003;113(1):81–100.

**ao L, Ai X, Cao Y, Yang H. Application of biphenyl electroploymerization for overcharge protection in Li-ion batteries. Electrochemistry. 2003;9(1):23–9.

Lee YG, Cho J. 3-Chloroanisole for overcharge protection of a Li-ion cell. Electrochim Acta. 2007;52(25):7404–8.

Xu M, **ng L, Li W, Zuo X, Shu D, Li G. Application of cyclohexyl benzene as electrolyte additive for overcharge protection of lithium ion battery. J Power Sources. 2008;184(2):427–31.

Leising R, Palazzo M, Takeuchi E, Takeuchi K. Abuse testing of lithium-ion batteries—characterization of the overcharge reaction of LiCoO2/graphite cells. J Power Sources. 2012;208:210–24.

Ohsaki T, Kishi T, Kuboki T. Overcharge reaction of lithium-ion batteries. J Power Sources. 2005;146(1):97–100.

Feng X, Fang M, He X, Ouyang M, Lu L, Wang H, Zhang M. Thermal runaway features of large format prismatic lithium ion battery using extended volume accelerating rate calorimetry. J Power Sources. 2014;255:294–301.

Doughty DH, Roth EP. A general discussion of Li-ion battery safety. Electrochem Soc Interface. 2012;21(2):37–44.

Lamb J, Orendorff CJ, Amine K, Krumdick G, Zhang Z, Zhang L, et al. Thermal and overcharge abuse analysis of a redox shuttle for overcharge protection of LiFePO4. J Power Sources. 2012;247:1011–7.

Jhu C, Wang Y, Wen C, Shu C. Thermal runaway potential of LiCoO2 and Li(Ni1/3Co1/3Mn1/3)O2 batteries determined with adiabatic calorimetry methodology. Appl Energy. 2012;100:127–31.

Erol S, Orazem ME, Muller RP. Influence of overcharge and over-discharge on the impedance response of LiCoO2/C batteries. J Power Sources. 2014;270:92–100.

Ouyang M, Ren D, Lu L, Li J, Feng X, Han X, et al. Overcharge-induced capacity fading analysis for large format lithium-ion batteries with LiyNi1/3Co1/3Mn1/3O2 + LiyMn2O4 composite cathode. J Power Sources. 2015;279:626–35.

Wang H, Tang A, Wang K. Thermal behavior investigation of LiNi1/3Co1/3Mn1/3O2-based Li-ion battery under overcharged test. Chin J Chem. 2011;29(1):27–32.

Ye J, Chen H, Wang Q, Huang P, Sun J, Lo S. Thermal behavior and failure mechanism of lithium ion cells during overcharge under adiabatic conditions. Appl Energy. 2016;182:464–74.

Uhlmann C, Illig J, Ender M, Schuster R, Tiffee EI. In situ detection of lithium metal plating on graphite in experimental cells. J Power Sources. 2015;279:428–38.

Burns JC, Stevens DA, Dahn JR. In-situ detection of lithium plating using high precision coulometry. J Electrochem Soc. 2015;162(6):A959–64.

Deng Y, Ma Z, Song X, Cai Z, Pang P, Wang Z, et al. From the charge conditions and internal short-circuit strategy to analyze and improve the overcharge safety of LiCoO2/graphite batteries. Electrochim Acta. 2018;282:295–303.

Deng Y, Kang T, Song X, Ma Z, Zuo X, Shu D, et al. Analysis on the constant-current overcharge electrode process and self-protection mechanism of LiCoO2/graphite batteries. J Solid State Electrochem. 2019;23:407–17.

Wang Z, Mao N, Jiang F. Study on the effect of spacing on thermal runaway propagation for lithium-ion batteries. J Therm Anal Calorim. 2020;140:2849–63.

Lanas SG, Valiente M, Tolazzi M, Melchior A. Thermodynamics of Hg2+ and Ag+ adsorption by 3-mercaptopropionic acid-functionalized superparamagnetic iron oxide nanoparticles. J Therm Anal Calorim. 2019;136:1153–62.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, W., Jiang, J. & Wen, J. Thermal runaway induced by dynamic overcharge of lithium-ion batteries under different environmental conditions. J Therm Anal Calorim 146, 855–863 (2021). https://doi.org/10.1007/s10973-020-10037-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-10037-x