Abstract

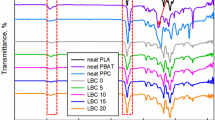

A phase-change energy storage microcapsule is prepared via emulsion polymerization, in which the copolymer of styrene (St) and methyl methacrylate (MMA) was used as shell material, n-octadecane as core material, sodium dodecyl benzene sulfonate (SDBS) as emulsifier. The morphology, phase-change thermal properties and thermal stability of microcapsule are characterized by particle size analyzer, transmission electron microscope, thermogravimetric analyzer (TG) and differential scanning calorimetry. The results show that the particle size of microcapsule is uniform, the dispersion of microcapsule particles is good, the microcapsule particles are well wrapped when poly(styrene–methyl methacrylate) copolymer (St/MMA = 1:5) is used as shell material, and SDBS content is 1.5 g (3% of the total mass). The initial temperature of exothermic peak is 31.9 °C, the termination temperature is 27.3 °C, the phase transition temperature is 28.9 °C, and the phase-change enthalpy is 48.39 J g−1. TG analysis shows that the long-term operating temperature of the microcapsule should not exceed 131 °C. IR analysis indicates that the obtained microcapsule contains core and shell material.

Similar content being viewed by others

References

Sharma RK, Ganesan P, Tyagi VV. Long-term thermal and chemical reliability study of different organic phase change materials for thermal energy storage applications. J Therm Anal Calorim. 2016;124:1357–66.

Sharma RK, Ganesan P, Tyagi VV, Metselaar HSC, Sandaran SC. Developments in organic solid–liquid phase change materials and their applications in thermal energy storage. Energy Convers Manag. 2015;95:193–228.

Liu M, Gomez JC, Turchi CS, Tay NHS, Saman W, Bruno F. Determination of thermo-physical properties and stability testing of high-temperature phase-change materials for CSP applications. Sol Energy Mater Sol Cells. 2015;139:81–7.

Rastogi M, Chauhan A, Vaish R, Kishan A. Selection and performance assessment of phase change materials for heating, ventilation and air-conditioning applications. Energy Convers Manag. 2015;89:260–9.

Chen ZH, Yu F, Zeng XR, Zhang ZG. Preparation, characterization and thermal properties of nanocapsules containing phase change material n-dodecanol by miniemulsion polymerization with polymerizable emulsifier. Appl Energy. 2012;91:7–12.

Diaconu BM, Varga S, Oliveira AC. Experimental assessment of heat storage properties and heat transfer characteristics of a phase change material slurry for air conditioning applications. Appl Energy. 2010;87:620–8.

Chen Z, Fang GY. Preparation and heat transfer characteristics of microencapsulated phase change material slurry: a review. Renew Sustain Energy Rev. 2011;15:4624–32.

Shen YW, Gu JY, Tan HY, Lv SS, Zhang YH. Preparation and properties of a polyvinyl alcohol toughened urea-formaldehyde foam for thermal insulation applications. Constr Build Mater. 2016;120:104–11.

Mei DD, Zhang B, Liu RC, Zhang YT, Liu JD. Preparation of capric acid/halloysite nanotube composite as form-stable phase change material for thermal energy storage. Sol Energy Mater Sol Cells. 2011;95:2772–7.

Wang YL, He ZG, Zhan L, Liu X. Coal tar pitch based carbon foam for thermal insulating material. Mater Lett. 2016;169:95–8.

Wu T, Meng JS. Research and realization of temperature control system of virtual heater with electrical heating material based on LabVIEW. Adv Mater Res. 2012;485:48–51.

Liu SQ, Duvigneau J, Vancso GJ. Nanocellular polymer foams as promising high performance thermal insulation materials. Eur Polym J. 2015;65:33–45.

Liu HG, Li TH, Shi YC, Zhao X. Thermal insulation composite prepared from carbon foam and silica aerogel under ambient pressure. J Mater Eng Perform. 2015;24:4054–9.

Zuo MM, Liu TQ, Han JJ, Tang YC, Yao F, Yuan YF, Qian ZH. Preparation and characterization of microcapsules containing ammonium persulfate as core by in situ polymerization. Chem Eng J. 2014;249:27–33.

Sato K, Nakajima T, Anzai JI. Preparation of poly(methyl methacrylate) microcapsules by in situ polymerization on the surface of calcium carbonate particles. J Colloid Interface Sci. 2012;387:123–6.

Palanikkumaran M, Gupta KK, Agrawal AK, Jassal M. Highly stable hexamethylolmelamine microcapsules containing n-octadecane prepared by in situ encapsulation. J Appl Polym Sci. 2009;114:2997–3002.

Salaün F, Devaux E, Bourbigot S, Rumeau P. Influence of process parameters on microcapsules loaded with n-hexadecane prepared by in situ polymerization. Chem Eng J. 2009;155:457–65.

Yang ZJ, Ding L, Wu P, Liu YG, Nie FD, Huang FL. Fabrication of RDX, HMX and CL-20 based microcapsules via in situ polymerization of melamine-formaldehyde resins with reduced sensitivity. Chem Eng J. 2015;268:60–6.

Wang Y, Zhang Y, Yang WH, Ji H. Selection of low-temperature phase-change materials for thermal energy storage based on the VIKOR method. Energy Technol. 2015;3:84–9.

Sari A, Alkan C, Karaipekli A, Uzun O. Microencapsulated n-octacosane as phase change material for thermal energy storage. Sol Energy. 2009;83:1757–63.

Acknowledgements

This work was supported by 2014 graduate student innovation research of Qiqihar University, China (YJSCX2014-001X).

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Wu, W., Zuo, H. Preparation and characterization of n-octadecane/poly(styrene–methyl methacrylate) phase-change microcapsule. J Therm Anal Calorim 130, 861–867 (2017). https://doi.org/10.1007/s10973-017-6470-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-017-6470-6