Abstract

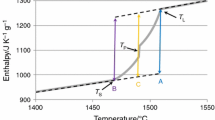

The determination of the solidification characteristics of alloys using differential scanning calorimetry (DSC) is difficult because of the unknowns associated with the kinetic of phase transformations and the thermal resistance between the sample and the temperature measuring device. This paper shows how appropriate assumptions coupled with a thermodynamic software package and an accurate mathematical analysis of a power-compensated DSC, can enable a direct comparison between the experimental and the theoretical heat evolutions obtained during the solidification of a multiphase alloy. This comparison is helpful in order to assess the thermodynamic database and to validate the different assumptions made in the solidification model.

Similar content being viewed by others

References

Coutinho JAP, Calange S, Ruffier-Meray V. Measuring the amount of crystallinity in solutions using DSC. Can J Chem Eng. 1997;75(6):1075–9. doi:10.1002/cjce.5450750610.

Dong HB, Shin MRM, Kurum EC, Cama H, Hunt JD. Determination of liquid fraction during solidification of aluminium alloys using a single-pan scanning calorimeter. Fluid Phase Equilib. 2003;212(1–2):199–208. doi:10.1016/S0378-3812(03)00257-7.

Sabau A, Porter W. Analysis of a heat-flux differential scanning calorimetry instrument. Metall Mater Trans A. 2007;38(7):1546–54. doi:10.1007/s11661-007-9136-3.

Mirković D, Schmid-Fetzer R. Solidification curves for commercial Mg alloys determined from differential scanning calorimetry with improved heat-transfer modeling. Metall Mater Trans A. 2007;38(10):2575–92. doi:10.1007/s11661-007-9237-z.

Rady M. Study of phase changing characteristics of granular composites using differential scanning calorimetry. Energy Convers Manag. 2009;50(5):1210–7. doi:10.1016/j.enconman.2009.01.030.

Chen S-W, Lin C-C, Chen C. Determination of the melting and solidification characteristics of solders using differential scanning calorimetry. Metall Mater Trans A. 1998;29(7):1965–72. doi:10.1007/s11661-998-0022-4.

Larouche D, Laroche C, Bouchard M. Analysis of differential scanning calorimetric measurements performed on a binary aluminium alloy. Acta Mater. 2003;51(8):2161–70. doi:10.1016/S1359-6454(03)00003-X.

Birol Y. Solid fraction analysis with DSC in semi-solid metal processing. J Alloys Compd. 2009;486(1–2):173–7. doi:10.1016/j.jallcom.2009.06.165.

Dong HB, Shin MRM, Kurum EC, Hunt JD, Cama H. A study of micro segregation in Al–Cu using a novel single-pan scanning calorimeter. Metall Mater Trans A. 2003;34(3):441–7. doi:10.1007/s11661-003-0080-6.

Larouche D. Computation of solidification paths in multiphase alloys with back-diffusion. Calphad. 2007;31(4):490–504. doi:10.1016/j.calphad.2007.04.002.

Acknowledgements

Financial assistance received from the Natural Sciences and Engineering Research Council of Canada (NSERC), Rio-Tinto-Alcan (RTA) and Fonds québécois de la recherche sur la nature et les technologies by the intermediary of the Aluminium Research Centre (REGAL) is gratefully acknowledged. The authors would also like to express their deepest gratitude to professor X. Grant Chen from the Université du Québec à Chicoutimi.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Larouche, D., Javidani, M. Mathematical analysis of the heat measured by a power-compensated differential scanning calorimeter during the solidification of a multiphase alloy. J Therm Anal Calorim 122, 197–205 (2015). https://doi.org/10.1007/s10973-015-4760-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-4760-4