Abstract

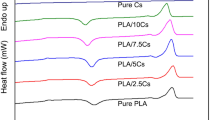

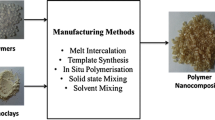

Many thermoplastic biocomposites made with non-biodegradable polymers as a matrix polymer are not biodegradable. In this work, biodegradable polylactide (PLA)/chitin micro-particle composites were successfully prepared by melt blending without using any compatibilizer or processing aid. The effects of the addition of chitin micro-particles to PLA on its thermal stability, physicomechanical properties and microstructures were evaluated by thermo-gravimetric analysis, dynamic mechanical thermal analysis, differential scanning calorimetry, tensile strength measurement, and scanning electron microscopy. It was found that the addition of chitin micro-particle to PLA increased the stiffness, tensile strength, and hydrophobicity of PLA but negatively affected its thermal properties and elongation. The tensile strength exhibited by the pristine PLA was 41.5 MPa, which increased to 48.5 for the chitin loading of 3% but a further increase in the chitin loading resulted in a reduction in tensile strength. The increase in chitin loading resulted in an increase in stiffness of PLA as the storage modulus increased from 3.21 GPa for the neat PLA to 3.48 GPa for the PLA loaded with 3% chitin microparticles. The results show that chitin can be used for the reinforcement and also to enhance the moisture barrier properties of PLA.

Similar content being viewed by others

References

Anand P, Rajesh D, Senthil Kumar M, Saran Raj I (2018) Investigations on the performances of treated jute/Kenaf hybrid natural fiber reinforced epoxy composite. J Polym Res 25:94

Qian X, ** J, Lu L, Shao G, Jiang S (2017) Preparation of poly(methyl methacrylate) /silicon particle composites and the study of the properties improvement. J Polym Res 24:45

Hassan MM, Le Guen MJ, Tucker N, Parker K (2019) Thermo-mechanical, morphological and water absorption properties of thermoplastic starch/cellulose composite foams reinforced with PLA. Cellulose 26:4463–4478

Siddique R, Khatib J, Kaur I (2008) Use of recycled plastic in concrete: a review. Waste Manag 28:1835–1852

Jambeck JR, Geyer R, Wilcox C, Siegler TR, Perryman M, Andrady A, Narayan R (2015) Plastic waste inputs from land into the ocean. Science 347:768–771

Cózar A, Echevarría F, González-Gordillo JI, Irigoien X, Úbeda B, Hernández-León S, Palma AT, Navarro S, García-de-Lomas J, Ruiz A, Fernández-de-Puelles ML, Duarte CM (2014) Plastic debris in the open ocean. Proc Natl Acad Sci USA 111:10239–10244

Yang TH, Kim TW, Kang HO, Lee S-H, Lee EJ, Lim S-C, Oh SO, Song A-J, Park SJ, Lee SY (2010) Biosynthesis of polylactic acid and its copolymers using evolved propionate CoA transferase and PHA synthase. Biotechnol Bioeng 105:150–160

Schmidt S, Scherkus C, Muschiol J, Menyes U, Winkler T, Hummel W, Gröger H, Liese A, Herz H-G, Bornscheuer UT (2015) An enzyme cascade synthesis of ε-caprolactone and its oligomers. Angew Chem 54:2784–2787

Labruyère C, Talon O, Berezina N, Khousakoun E, Jérôme C (2014) Synthesis of poly(butylene succinate) through oligomerization-cyclization- ROP route. RSC Adv 4:38643–38648

Marang L, Jiang Y, van Loosdrecht MCM, Kleerebezem R (2013) Butyrate as preferred substrate for polyhydroxybutyrate production. Bioresour Technol 142:232–239

Wang Y, Chen R, Cai JY, Liu Z, Zheng Y, Wang H, Li Q, He N (2013) Biosynthesis and thermal properties of PHBV produced from levulinic acid by Ralstonia eutropha. PLoS One 8:e60318

Harris AM, Lee EC (2008) Improving mechanical performance of injection molded PLA by controlling crystallinity. J Appl Polym Sci 107:2246–2255

Mallet B, Lamnawar K, Maazouz A (2014) Improvement of blown film extrusion of poly(lactic acid): structure-processing-properties relationships. Polym Eng Sci 54:840–857

Karkhanis SS, Stark NM, Sabo RC, Matuana LM (2017) Blown film extrusion of poly(lactic acid) without melt strength enhancers. J Appl Polym Sci 134:45212

Zhang B, Seong B, Nguyen V, Byun D (2016) 3D printing of high-resolution PLA-based structures by hybrid electrohydrodynamic and fused deposition modeling techniques. J Micromech Microeng 26:025015

Wang H, Sun XZ, Seib P (2001) Strengthening blends of poly(lactic acid) and starch with methylene - diphenyl diisocyanate. J Appl Polym Sci 82:1761

Frone AN, Berlioz S, Chailan JF, Panaitescu DM, Donescu D (2011) Cellulose fiber-reinforced polylactic acid. Polym Compos 32:976–985

Gherissi A, Cheikh RB, Dévaux E, Abbassi F (2012) Cellulose whiskers micro-fibers effect in the mechanical proprieties of PP and PLA composites fibers obtained by spinning process. Appl Mechanic Mater 146:12–26

Hassan MM, Koyama K (2015) Enhanced thermal, mechanical and fire-retarding properties of polystyrene sulphonate-grafted-nanosilica/polypropylene composites. RSC Adv 5:16950–16959

Muiruri JK, Liu S, Teo WS, Kong J, He C (2017) Highly biodegradable and tough polylactic acid-cellulose nanocrystal composite. ACS Sustain Chem Eng 5:3929–3937

Johari AP, Kurmvanshi SK, Mohanty S, Nayak SK (2016) Influence of surface modified cellulose microfibrils on the improved mechanical properties of poly (lactic acid). Int J Biol Macromol 84:329–339

Qian S, Sheng K, Yu K, Xu L, Fontanillo Lopez CA (2018) Improved properties of PLA biocomposites toughened with bamboo cellulose nanowhiskers through silane modification. J Mater Sci 53:10920–10932

Yuryev Y, Mohanty AK, Misra M (2017) Novel durable biocomposites from biobased PC/PLA blend matrix system. Composites B 130:158–166

Gil-Castell O, Badia JD, Kittikorn T, Strömberg E, Ek M, Karlsson S, Ribes-Greus A (2016) Impact of hydrothermal aging on the thermal stability, morphology and viscoelastic performance of PLA/sisal biocomposites. Polym Degrad Stab 132:87–96

Cuevas-Carballo ZB, Duarte-Aranda S, Canché-Escamilla G (2017) Properties and biodegradability of thermoplastic starch obtained from granular starches grafted with polycaprolactone. Int J Polym Sci 2017:3975692

Weerapoprasit C, Prachayawarakorn J (2019) Characterization and properties of biodegradable thermoplastic grafted starch films by different contents of methacrylic acid. Int J Biol Macromol 123:657–663

Modelli A, Rondinelli G, Scandola M, Mergaert J, Cnockaert MC (2004) Biodegradation of chemically modified flax fibers in soil and in vitro with selected bacteria. Biomacromolecules 5:596–602

Singh AA, Wei J, Herrera N, Geng S, Oksman K (2018) Synergistic effect of chitin nanocrystals and orientations induced by solid-state drawing on PLA-based nanocomposite tapes. Compos Sci Technol 162:140–145

Mahmoodi A, Ghodrati S, Khorasani M (2019) High-strength, low-permeable, and light-protective nanocomposite films based on a hybrid nanopigment and biodegradable PLA for food packaging applications. ACS Omega 4:14947–14954

Lertphirun K, Srikulkit K (2019) Properties of poly(lactic acid) filled with hydrophobic cellulose/SiO2 composites. Int J Polym Sci Art ID 7835172

Ahmed J, Varshney SK (2011) Polylactides-chemistry properties and green packaging technology: a review. Int J Food Prop 14:37–58

Cárdenas G, Cabrera G, Taboada E, Miranda SP (2004a) Chitin characterization by SEM, FTIR, XRD, and 13C cross polarization/mass angle spinning NMR. J Appl Polym Sci 93:1876–1885

Duarte ML, Ferreira MC, Marvão MR, Rocha J (2002) An optimized method to determine the degree of acetylation of chitin and chitosan by FTIR spectroscopy. Int J Biol Macromol 31:1–8

Cárdenas G, Cabrera G, Taboada E, Miranda SP (2004b) Chitin characterization by SEM, FTIR, XRD, and13C cross polarization/mass angle spinning NMR. J Appl Polym Sci 93:1876–1885

Chen P-Y, Lian H-Y, Shih Y-F, Chen-Wei S-M, Jeng R-J (2017) Preparation, characterization and crystallization kinetics of kenaf fiber/multi-walled carbon nanotube/polylactic acid (PLA) green composites. Mater Chem Phys 196:249–255

Herrera N, Roch H, Salaberria AM, Pino-Orellana MA, Labidi J, Fernandes SCM, Radic D, Leiva A, Oksman K (2016) Functionalized blown films of plasticized polylactic acid/chitin nanocomposite: preparation and characterization. Mater Design 92:846–852

Spiridon I, Paduraru OM, Zaltariov MF, Darie RN (2013) Influence of keratin on polylactic acid/chitosan composite properties: behavior upon accelerated weathering. Ind Eng Chem Res 52:9822–9833

Rocca-Smith JR, Lagorce-Tachon A, Iaconelli C, Bellat JP, Marcuzzo E, Sensidoni A, Piasente F, Debeaufort F, Karbowiak T (2017) How high-pressure CO2 impacts PLA film properties. Express Polym Lett 11:320–333

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hassan, M.M., Koyama, K. Thermomechanical and viscoelastic properties of green composites of PLA using chitin micro-particles as fillers. J Polym Res 27, 27 (2020). https://doi.org/10.1007/s10965-019-1991-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-019-1991-2