Abstract

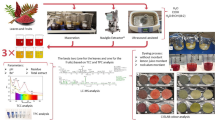

Conventional reduction process of indigo dyes with sodium dithionite produced lots of harmful byproducts and caused environmental pollution. A new reduction method should be introduced to textile dyer so that reduction can be less hazardous with low impact on the environment and energy resources. This study investigates an alternative reducing agent obtained from natural resources. Three different types of reducing agent are used, extracted from the Date palm, Banana and Apple by boiling method. To compare their effect on the reduction of the natural indigo dyestuff, different color fastness properties, pH and the color yield (K/S) were measured according to the concentration of reducing agent and hydrated lime concentration. Outcomes show that K/S value varies with the amount of reducing agent. Average higher value shows from date palm among the three reducing agents at 25 °C & pH range 10.8–11. By using natural reducing agents, it can be possible to get satisfactory colorfastness and depth of shed compared to a synthetic reducing agent.

Similar content being viewed by others

References

Bansal P, Roth K (2000) Acad Manag J 43:717–736

Esty D, Andrew W (2009) Green to gold: how smart companies use environmental strategy to innovate, create value, and build competitive advantage. Wiley, New York, pp 3–7

Mansour R, Ezzili B, Farouk M (2013) Fiber Polym. 14:786

Avine O, Celik A, Geduk G, Yavas A (2013) Fiber Polym. 14:866

Prabhu KH, Teli MD, Waghmare NG (2011) Fiber Polym. 12:753

Zhang R, Cai Z (2011) Fiber. Polym. 12:478

Shahid M, Mohammad F (2013) Perspectives for natural product based agents derived from industrial plants in textile applications–a review. J Clean Prod 57:2–18

Bechtold T, Turcanu A (2009) J Clean Prod 17:1669

Semet B, Säckingen B, Grüningen GE (1995) MelliandTextilber 76:161–164

Chavan RB (2001) Indian J Fibre Text 26:93–100

Padden AN, John P, Collins MD, Hutson R, Hall AR (2000) J Archaeol Sci 27:953–956

Roessler A, ** X (2003) Dyes Pigments 59:223–235

Božič M, Kokol V (2008) Dyes Pigments 76:299–309

Roessler A, Crettenand D (2004) Dyes Pigments 63:29–37

Shin Y, Choi M, Dong DI (2013) Fiber Polym 14:2027–2031

Mongkholrattanasit R, Wiener J, Studničkova J (2010) Fiber Polym 11:346–350

Zhu L, Wang Y, He T, You L, Shen X (2016) Assessment of potential capability of water bamboo leaves on the adsorption removal efficiency of cationic dye from aqueous solutions. J Polym Environ 24:148–158

Gomes AP, Mano JF, Queiroz JA, Gouveia IC (2012) Layer-by-layer deposition of antibacterial polyelectrolytes on cotton fibres. J Polym Environ 20(4):1084–1094

Choudhury AR (2006) Textile preparation and dyeing. Science Publishers

Lee YH, Kim HD (2004) Fiber Polym 5:303

Cristea D, Vilarem G (2006) Dyes Pigments 70:238

Elnagar KE, Tera FM, Mohamed SM (2012) J Text Appar Technol Manag 7:1–6

Madhu A (2012) J Text Appar Technol Manag 7:1–13

Bhuiyan MR, Hossain MA, Zakaria M, Islam MN, Uddin MZ (2016) Chitosan coated cotton fiber: physical and antimicrobial properties for apparel use. J Polym Environ 1–9. doi:10.1007/s10924-016-0815-2

Agarwal BJ, Bhattacharya SD (2010) Possibilities of polymer-aided dyeing of cotton fabric with reactive dyes at neutral pH. J Appl Polym Sci 118(3):1257–1269

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hossain, M.D., Khan, M.M.R. & Uddin, M.Z. Fastness Properties and Color Analysis of Natural Indigo Dye and Compatibility Study of Different Natural Reducing Agents. J Polym Environ 25, 1219–1230 (2017). https://doi.org/10.1007/s10924-016-0900-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-016-0900-6