Abstract

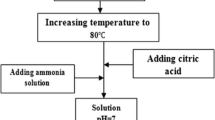

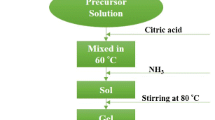

Ba0.5Sr0.5AlxFe12-xO19 was synthesized by systematically altering the Al-to-Fe content (x = 0, 1, 2, 3, 4) through the substitution of iron cations with an equivalent amount of aluminum cations. The powder was synthesized using the sol–gel auto-combustion method, resulting in a well-defined particle size distribution. This work aims to study the synthesis conditions for preparing barium strontium hexaferrite, and then the material properties was characterized by Thermogravimetric Analysis (TGA) and Differential Scanning Calorimetry (DSC), X-ray Powder Diffraction (XRD), Scanning Electron Microscopy (SEM), Fourier Transform Infrared Spectroscopy (FTIR), and Vibrating Sample Magnetometer (VSM). The structure of the Al-substituted hexaferrite sample was confirmed using X-ray diffraction with the presence of a hexagonal phase. Using FESEM, the average particle size was found to be 76.35 nm. The magnetic properties of the barium strontium hexaferrite (BSFO) and the Al-substituted BSFO material were studied at room temperature using VSM by knowing the value of coercivity (Hc), saturation magnetization (Ms), retentivity (Mr), squareness ratio (Mr/Ms) for the permanent magnet application. The M-H loop and B-H loop provide insights into the ferromagnetic characteristics of the material. Additionally, the material is assessed to determine its maximum energy storage capacity, denoted as (BH)max. The coercivity of the material was increased from 5206 to 9189 Oe whereas, the saturation value decreased with the increase in the content of Al. The energy product (BH)max for pure BSFO was 13 kJ/m3 and this value were also estimated for different compositions of the material.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available upon request from the authors.

References

R.C. Pullar, Prog. Mater. Sci. 57, 1191 (2012)

S. Kanagesan, M. Hashim, S. Jesurani, T. Kalaivani, I. Ismail, M.S.E. Shafie, J. Alloys Compd. 543, 49 (2012)

P. **g, J. Du, J. Wang, J. Wei, L. Pan, J. Li, Q. Liu, Sci. Rep. 5, 1 (2015)

F.M.M. Pereira, C.A.R. Junior, M.R.P. Santos, R.S.T.M. Sohn, F.N.A. Freire, J.M. Sasaki, J.A.C. Paiva, A.S.B. Sombra, J. Mater. Sci. Mater. Electron. 19, 627 (2008)

P. Sharma, R.A. Rocha, S.N. de Medeiros, A. Paesano, J. Alloys Compd. 443, 37 (2007)

H. Joshi, A.R. Kumar, J. Mater. Sci. Mater. Electron. 32, 4331 (2021)

D. Shekhawat, P.K. Roy, Mater. Sci. Eng. B 293, 116461 (2023)

A. Thakur, R.R. Singh, P.B. Barman, J. Magn. Magn. Mater. 326, 35 (2013)

H. Luo, B.K. Rai, S.R. Mishra, V.V. Nguyen, J.P. Liu, J. Magn. Magn. Mater. 324, 2602 (2012)

X. Meng, J. Gao, Y. Lu, J. Sol-Gel Sci. Technol. 64, 86 (2012)

J. Luo, Mater. Lett. 80, 162 (2012)

S. Ounnunkad, P. Winotai, J. Magn. Magn. Mater. 301, 292 (2006)

C.J. Li, B.N. Huang, J.N. Wang, J. Mater. Sci. 48, 1702 (2013)

H.Z. Wang, Y.N. Hai, B. Yao, Y. Xu, L. Shan, L. Xu, J.L. Tang, Q.H. Wang, J. Magn. Magn. Mater. 422, 204 (2017)

Z. Yue, W. Guo, J. Zhou, Z. Gui, L. Li, J. Magn. Magn. Mater. 270, 216 (2004)

A. Sutka, G. Mezinskis, Front. Mater. Sci. 6, 128 (2012)

S.N. Rout, M.K. Manglam, J. Mallick, S. Datta, M. Kar, Phys. B Condens. Matter 666, 415134 (2023)

B. Niu, F. Zhang, H. **, N. Li, J. Zhou, L. Lei, J. **e, J. Zhang, W. Wang, Z. Fu, Sci. Rep. 7, 1 (2017)

M.A. Marjeghal, A. Sedghi, S. Baghshahi, J. Alloys Compd. 968, 171765 (2023)

A. Nag, R.S.C. Bose, K.S. Venu, H. Singh, Ceram. Int. 48, 15303 (2022)

E.A. Gorbachev, V.A. Lebedev, E.S. Kozlyakova, L.N. Alyabyeva, A. Ahmed, A. Cervellino, L.A. Trusov, Ceram. Int. 49, 26411 (2023)

K. Rekha, R.E. Vizhi, Results Phys. 44, 106139 (2023)

Z. Sabouri, M. Sabouri, M.S. Amiri, M. Khatami, M. Darroudi, Mater. Technol. 37, 555 (2022)

S. Kanagesan, S. Jesurani, R. Velmurugan, S. Prabu, T. Kalaivani, J. Mater. Sci. Mater. Electron. 23, 1127 (2012)

S.A. Mathews, D.R. Babu, P. Saravanan, Y. Hayakawa, Mater. Chem. Phys. 252, 123063 (2020)

P.A. Mariño-Castellanos, J.C. Somarriba-Jarque, J. Anglada-Rivera, Phys. B Condens. Matter 362, 95 (2005)

V.P. Singh, G. Kumar, J. Shah, A. Kumar, M. Dhiman, R.K. Kotnala, M. Singh, Ceram. Int. 41, 11693 (2015)

A. Hojjati Najafabadi, R. Mozaffarinia, A. Ghasemi, J. Supercond. Nov. Magn. 28, 2821 (2015)

S.T. Abarna, R. Ezhil Vizhi, V. Harikrishnan, Results Phys. 48, 106419 (2023)

Z. Sabouri, S. Sabouri, S.S.T.H. Moghaddas, A. Mostafapour, S.M. Gheibihayat, M. Darroudi, Biomass Convers. Biorefinery 1 (2022). https://doi.org/10.1007/s13399-022-02907-1

Z. Sabouri, M. Sabouri, S.S.T.H. Moghaddas, A. Mostafapour, S. Samarghandian, M. Darroudi, Biomass Convers. Biorefinery 1 (2023). https://doi.org/10.1007/s13399-023-04984-2

S. Singhal, T. Namgyal, J. Singh, K. Chandra, S. Bansal, Ceram. Int. 37, 1833 (2011)

F. Khademi, A. Poorbafrani, P. Kameli, H. Salamati, J. Supercond. Nov. Magn. 25, 525 (2012)

M. Liu, X. Shen, F. Song, J. **ang, X. Meng, J. Solid State Chem. 184, 871 (2011)

Z. Sabouri, R.K. Oskuee, S. Sabouri, S.S.T.H. Moghaddas, S. Samarghandian, H.S. Abdulabbas, M. Darroudi, Ceram. Int. 49, 20989 (2023)

Z. Sabouri, S. Sabouri, S.S.T.H. Moghaddas, A. Mostafapour, M.S. Amiri, M. Darroudi, Bioprocess Biosyst. Eng. 45, 1799 (2022)

K. Habanjar, H. Shehabi, A.M. Abdallah, R. Awad, Appl. Phys. A (2020). https://doi.org/10.1007/s00339-020-03497-3

S. Torkian, A. Ghasemi, R. ShojaRazavi, M. Tavoosi, J. Supercond. Nov. Magn. 29, 1627 (2016)

L.A. Trusov, E.A. Gorbachev, V.A. Lebedev, A.E. Sleptsova, I.V. Roslyakov, E.S. Kozlyakova, A.V. Vasiliev, R.E. Dinnebier, M. Jansen, P.E. Kazin, Chem. Commun. 54, 479 (2018)

M. Shezad, X. Liu, S. Feng, X. Kan, W. Wang, C. Liu, T.J. Shehzad, K.M.U. Rehman, J. Magn. Magn. Mater. 497, 166013 (2020)

Q. Fang, H. Cheng, K. Huang, J. Wang, R. Li, Y. Jiao, J. Magn. Magn. Mater. 294, 281 (2005)

S. Singhal, A.N. Garg, K. Chandra, J. Magn. Magn. Mater. 285, 193 (2005)

A. Gupta, M. Kar, P.K. Roy, Mater. Chem. Phys. 292, 126842 (2022)

H.Z. Wang, B. Yao, Y. Xu, Q. He, G.H. Wen, S.W. Long, J. Fan, G.D. Li, L. Shan, B. Liu, L.N. Jiang, L.L. Gao, J. Alloys Compd. 537, 43 (2012)

J. Dho, E.K. Lee, J.Y. Park, N.H. Hur, J. Magn. Magn. Mater. 285, 164 (2005)

P. Behera, S. Ravi, J. Supercond. Nov. Magn. 30, 1453 (2017)

A.R. Makhdoom, Q.A. Ranjha, U.U.R. Ghori, M.A. Raza, B. Raza, M.E. Mazhar, K.A. Rao, F. Ahmed, S.U. Asif, M.W. Khan, M. Nisa, Phys. Scr. 96(12), 125865 (2021). https://doi.org/10.1088/1402-4896/ac3d4f

H. Irfan, R. Ezhil Vizhi, Nanotechnology 31(40), 404001 (2020)

Acknowledgements

The authors are thankful to the management, Vellore Institute of Technology, Vellore, Tamilnadu, India for their constant support and the characterization facilities provided for this work. We acknowledge the Nanotechnology Research Centre (NRC), SRMIST for providing the VSM facilities. The authors would like to express their gratitude to all the members of the laboratory as well.

Funding

No funding was received to assist with the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

JM: investigation, writing—original draft. REV: supervision, writing—review & editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Ethical approval

The authors declare that this manuscript complies with scientific ethical standards. Furthermore, this article does not contain any studies involving human or animal participants.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Manoj, J., Vizhi, R.E. Effect of Al substitution on their structural and magnetic properties of Ba0.5Sr0.5Fe12O19 prepared via sol–gel auto-combustion method. J Mater Sci: Mater Electron 35, 370 (2024). https://doi.org/10.1007/s10854-024-12037-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-024-12037-1