Abstract

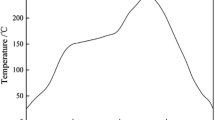

The influence of nano-ZnO particles addition on wettability, thermal behavior and interface morphology of Sn–3.0Ag–0.5Cu (SAC305) lead-free solder were investigated in present study. SAC305-xZnO composite solder with five different mass fractions of nano-ZnO particles ranging from 0 to 2.0 wt% were synthesized with SAC305 powder, nano-ZnO particles and flux. Solder joints were soldered in a reflow furnace with the maximum temperature of 255 °C for 7 min and followed by isothermal aging at 170 °C up to 240 h. The results reveal that the wettability improves first and then reduces whereas the thickness of intermetallic compounds (IMCs) layer declines first and then increases with the amount of nano-ZnO particles increasing where the threshold occurs at 0.5 wt% nano-ZnO particles, meaning slight addition of nano-ZnO particles can effectively improve wettability as well as restrain IMCs layer growth. The thermal behaviors of SAC305-xZnO composite solder increases slightly as nano-ZnO particles adds from 0 to 2.0 wt%. Moreover, the diffusion coefficient of solder is 0.92 μm2/h, 0.21 μm2/h, 0.22 μm2/h, 0.37 μm2/h and 0.48 μm2/h in sequence with nano-ZnO particles increased from 0 to 2.0 wt%, revealing nano-ZnO particles can inhibit atoms diffusion so as to suppress IMCs layer. Furthermore, the grain size of Cu6Sn5 is observed that it increases with power function of aging time describing as \(d = 1.70t^{0.38}\). In the end, it reveals that Cu6Sn5 grows both longitudinally controlled by volume diffusion as well as transversely in the form of boundary diffusion.

Similar content being viewed by others

References

S.F. Cheng, C.M. Huang, M. Pecht, Microelectron. Reliab. 75, 77–95 (2017)

M.I.I. Ramli, N. Saud, M.A.A.M. Salleh, M.N. Derman, R.M. Said, Microelectron. Reliab. 65, 255–264 (2016)

O. Mokhtari, H. Nishikawa, Mater. Sci. Eng. 651, 831–839 (2016)

X.W. Hu, Q. Huang, Y.L. Li, Y. Liu, Z.X. Min, J. Mater. Sci.: Mater. Electron. 26, 5140–5151 (2015)

J. Shen, Y.C. Chan, J. Alloys Compds. 477, 552–559 (2009)

X.D. Liu, S.L. He, H. Nishikawa, J. Alloys Compds. 695, 2165–2172 (2017)

X.W. Hu, Y.L. Li, Z.X. Min, J. Alloy. Compd. 625, 241–250 (2015)

Y.C.L.X. Wang, C. Wei, H.X. Gao, P. Jiang, L.M. Yu, J. Alloys Compds. 476, 662–665 (2009)

M.A. Wadud, M.A. Gafur, M.R. Qadir, M.O. Rahman, Mater. Sci. Appl. 6, 1008–1013 (2015)

F. **ng, J. Yao, J.W. Liang, X.M. Qiu, J. Alloys Compds. 649, 1053–1059 (2015)

E. Çadırlı, U. Böyük, H. Kaya, N. Maraşlı, J. Non-Cryst Solids 357, 2876–2881 (2011)

X.X. Tu, D.Q. Yi, J. Wu, J. Alloys Compds. 698, 317–328 (2017)

J.X. Wang, H. Nishikawa, Microelectron. Reliab. 54, 1583–1591 (2014)

A.A. El-Daly, W.M. Desoky, T.A. Elmosalami, M.G. El-Shaarawy, A.M. Abdraboh, Mater. Des. 65, 1196–1204 (2015)

A.A. El-Daly, A.M. El-Taher, S. Gouda, Mater. Des. 65, 796–805 (2015)

Q.K. Zhang, W.M. Long, X.Q. Yu, Y.Y. Pei, P.X. Qiao, J. Alloys Compds. 622, 973–978 (2015)

B.L. Silva, N. Cheung, A. Garcia, J.E. Spinelli, Mater. Lett. 142, 163–167 (2015)

J. Chen, J. Shen, W.D. **e, H. Liu, J. Mater. Sci.: Mater. Electron. 22, 1703–1708 (2011)

B. Li, Y.W. Shi, Y.P. Lei, F. Guo, Z.D. **a, B. Zong, J. Electron. Mater. 34, 217–224 (2005)

M.A.A. Mohd Salleh, S.D. McDonald, C.M. Gourlay, H. Yasuda, K. Nogita, Mater. Des. 108, 418–428 (2016)

Y. Tang, S.M. Luo, K.Q. Wang, G.Y. Li, J. Alloys Compds. 684, 299–309 (2016)

S. Chellvarajoo, M.Z. Abdullah, Mater. Des. 90, 499–507 (2016)

W.Q. **ng, X.Y. Yu, H. Li, L. Ma, W. Zuo, P. Dong, W.X. Wang, M. Ding, Mater. Sci. Eng. A 678, 252–259 (2016)

Z. Zhang, X.W. Hu, X.X. Jiang, Y.L. Li, Metall. Mater. Trans. A 50, 480–492 (2019)

K. Suganuma, Lead-Free Soldering (Science Press, Bei**g, 2004), p. 70

A.A. El-Daly, G.S. Al-Ganainy, A. Fawzy, M.J. Younis, Mater. Des. 55, 837–845 (2014)

Y. Gu, X.C. Zhao, Y. Li, Y. Liu, Y. Wang, Z.Y. Li, J. Alloys Compds. 627, 39–47 (2015)

H.R. Kotadia, P.D. Howes, S.H. Mannan, Microelectron. Reliab. 54, 1253–1273 (2014)

L. Zhang, K.N. Tu, Mater. Sci. Eng. R 82, 1–32 (2014)

G.K. Sujan, A.S.M.A. Haseeb, A.B.M. Afifi, Mater. Charact. 97, 199–209 (2014)

Y. Tang, G.Y. Li, Y.C. Pan, J. Alloys Compds. 554, 195–203 (2013)

Y.W. Wang, Y.W. Lin, C.R. Kao, J. Alloys Compds. 493, 233–239 (2010)

J.J. Yu, C.A. Yang, Y.F. Lin, C.H. Hsueh, C.R. Kao, J. Alloys Compds. 629, 16–21 (2015)

H.Y. Chuang, J.J. Yu, M.S. Kuo, H.M. Tong, C.R. Kao, Scr. Mater. 66, 171–174 (2012)

C.K. Chung, Y.J. Chen, W.M. Chen, C.R. Kao, Acta Mater. 60, 4586–4593 (2012)

D.G. Kim, S.B. Jung, J. Alloys Compds. 386, 151–156 (2005)

J.X. Cheng, X.W. Hu, X.X. Jiang, Vacuum 159, 112–124 (2019)

H.K. Kim, K.N. Tu, J. Phys. Rev. B 53, 593–596 (1996)

M. Schaefer, R.A. Founelle, J. Liang, J. Electron. Mater. 27, 1167–1176 (1998)

H. Nishikawa, N. Lwata, J. Mater. Proc. Technol. 215, 6–11 (2015)

Acknowledgements

The authors would like to acknowledge the financial support provided by National Natural Science Foundation of China (NSFC) under Grant Nos. 51604012 and 51575004, Fundamental Research Project of Bei**g Municipal Education Commission, and Natural Science Foundation of Bei**g (NSFB) under Grant No. 3162010.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Qu, M., Cao, T., Cui, Y. et al. Effect of nano-ZnO particles on wettability, interfacial morphology and growth kinetics of Sn–3.0Ag–0.5Cu–xZnO composite solder. J Mater Sci: Mater Electron 30, 19214–19226 (2019). https://doi.org/10.1007/s10854-019-02279-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-02279-9