Abstract

The present study investigates the mechanical behavior of a SiCp/Mg–5Zn–0.2Ca composite under tensile loading using in-situ synchrotron X-ray diffraction. The composite exhibited a yield strength of 167 MPa, ultimate tensile strength of 276 MPa, and tensile elongation of 15%. It was found that the onset of micro-yielding at a stress level of approximately 40 MPa, which is attributed to the thermal and interfacial mismatches between the SiC particles and α-Mg matrix. Furthermore, load partitioning between the SiC particles and α-Mg grains was observed following the micro-yielding event, indicating micro-load transfer from the softer α-Mg grains to the SiC particles. The occurrence of microcracks at the SiC/Mg phase interfaces after the micro-yielding event may have implications for the composite’s overall fracture behavior. These findings underscore the influence of interfacial thermal mismatch on promoting micro-yielding in the composite. Several factors including reducing forming temperatures, utilizing reinforcements with lower coefficients of thermal expansion, and adjusting the alloying elements can be used to mitigate such micro-yielding effect.

Similar content being viewed by others

Data availability

Data will be made available on request.

References

Chen LY, Xu JQ, Choi H et al (2015) Processing and properties of magnesium containing a dense uniform dispersion of nanoparticles. Nature 528:539–543. https://doi.org/10.1038/nature16445

Hassan HA, Lewandowski JJ (2014) Effects of particulate volume fraction on cyclic stress response and fatigue life of AZ91D magnesium alloy metal matrix composites. Mater Sci Eng A 600:188–194

Chang Z, Wu Y, Iizuka T et al (2021) High-strength and high-modulus Al18B4O33W/GWZ1031K magnesium matrix composite prepared by squeeze casting. Mater Sci Eng A 817:141393

Ding C, Gan W, Hu X et al (2020) Investigation into the influence of carbon nanotubes addition on residual stresses and mechanical properties in the CNTs@ SiCp/Mg–6Zn hybrid composite using neutron diffraction method. Mater Sci Eng A 797:140105

Garcés G, Oñorbe E, Pérez P et al (2012) Influence of SiC particles on compressive deformation of magnesium matrix composites. Mater Sci Eng A 533:119–123

Deng K, Shi J, Wang C et al (2012) Microstructure and strengthening mechanism of bimodal size particle reinforced magnesium matrix composite. Compos Part A Appl Sci Manuf 43:1280–1284

Wang XJ, Wu K, Huang WX et al (2007) Study on fracture behavior of particulate reinforced magnesium matrix composite using in situ SEM. Compos Sci Technol 67:2253–2260

Garcés G, Oñorbe E, Pérez P et al (2009) Evolution of internal strain during plastic deformation in magnesium matrix composites. Mater Sci Eng A 523:21–26

Maurya P, Kota N, Gibmeier J et al (2022) Review on study of internal load transfer in metal matrix composites using diffraction techniques. Mater Sci Eng A 840:142973

Wang J, Zhu G, Wang L et al (2021) Origins of high ductility exhibited by an extruded magnesium alloy Mg–1.8Zn–0.2Ca: experiments and crystal plasticity modeling. J Mater Sci Technol 84:27–42. https://doi.org/10.1016/j.jmst.2020.12.047

Zhu G, Wang L, Zhou H et al (2019) Improving ductility of a Mg alloy via non-basal <a> slip induced by Ca addition. Int J Plast 120:164–179. https://doi.org/10.1016/j.ijplas.2019.04.020

Wang J, Zhu G, Wang L et al (2023) Strengthening mechanisms, hardening/softening behavior, and microstructure evolution in an LPSO magnesium alloy at elevated temperatures. Mater Charact. https://doi.org/10.1016/j.matchar.2023.113066

Berman TD, Pollock TM, Jones JW (2016) Microstructure and texture through thixomolding and thermomechanical processing and the role of Mg17Al12 Particles. Metall Mater Trans A Phys Metall Mater Sci 47:3125–3136. https://doi.org/10.1007/s11661-016-3450-6

Tu T, Chen X-H, Chen J et al (2019) A high-ductility Mg–Zn–Ca magnesium alloy. Acta Metall Sin (English Lett) 32:23–30

Wang J, Chen Y, Chen Z et al (2021) Deformation mechanisms of Mg–Ca–Zn alloys studied by means of micropillar compression tests. Acta Mater 217:117151

Orozco-Caballero A, Lunt D, Robson JD, Da Fonseca JQ (2017) How magnesium accommodates local deformation incompatibility: a high-resolution digital image correlation study. Acta Mater 133:367–379

Guan D, Wynne B, Gao J et al (2019) Basal slip mediated tension twin variant selection in magnesium WE43 alloy. Acta Mater 170:1–14

Stanford N, Cottam R, Davis B, Robson J (2014) Evaluating the effect of yttrium as a solute strengthener in magnesium using in situ neutron diffraction. Acta Mater 78:1–13

Wang J, Wang L, Zhu G et al (2018) Understanding the high strength and good ductility in LPSO-containing Mg alloy using synchrotron X-ray diffraction. Metall Mater Trans A 49:5382–5392

Zhou B, Wang L, Zhu G et al (2018) Understanding the strengthening effect of β 1 precipitates in Mg–Nd using in situ synchrotron X-ray diffraction. JOM 70:2315–2320

Kada SR, Lynch PA, Kimpton JA, Barnett MR (2016) In-situ X-ray diffraction studies of slip and twinning in the presence of precipitates in AZ91 alloy. Acta Mater 119:145–156

Garcés G, Máthis K, Medina J et al (2018) Combination of in-situ diffraction experiments and acoustic emission testing to understand the compression behavior of Mg–Y–Zn alloys containing LPSO phase under different loading conditions. Int J Plast 106:107–128

Jain A, Duygulu O, Brown DW et al (2008) Grain size effects on the tensile properties and deformation mechanisms of a magnesium alloy, AZ31B, sheet. Mater Sci Eng A 486:545–555

Baczmański A, Wroński M, Kot P et al (2021) The role of basal slip in the generation of intergranular stresses in magnesium alloy studied using X-ray diffraction and modelling. Mater Des 202:109543

Garcés G, Orozco-Caballero A, Da Fonseca JQ et al (2020) Initial plasticity stages in Mg alloys containing long-period stacking ordered phases using high resolution digital image correlation (HRDIC) and in-situ synchrotron radiation. Mater Sci Eng A 772:138716

Garcés G, Oñorbe E, Gan W et al (2017) Evolution of twinning in extruded AZ31 alloy with bimodal grain structure. Mater Charact 126:116–124

Garces G, Perez P, Cabeza S et al (2017) Effect of extrusion temperature on the plastic deformation of an Mg–Y–Zn alloy containing LPSO phase using in situ neutron diffraction. Metall Mater Trans A 48:5332–5343

Garces G, Medina J, Pérez P et al (2018) Influence of quasicrystal I-phase on twinning of extruded Mg–Zn–Y alloys under compression. Acta Mater 151:271–281

Garces G, Morris DG, Muñoz-Morris MA et al (2015) Plasticity analysis by synchrotron radiation in a Mg97Y2Zn1 alloy with bimodal grain structure and containing LPSO phase. Acta Mater 94:78–86. https://doi.org/10.1016/j.actamat.2015.04.048

Garcés G, Máthis K, Pérez P et al (2016) Effect of reinforcing shape on twinning in extruded magnesium matrix composites. Mater Sci Eng A 666:48–53

Braszczyńska KN, Lityńska L, Zyska A, Baliga W (2003) TEM analysis of the interfaces between the components in magnesium matrix composites reinforced with SiC particles. Mater Chem Phys 81:326–328

Yu W, Wang X, Zhao H et al (2017) Microstructure, mechanical properties and fracture mechanism of Ti2AlC reinforced AZ91D composites fabricated by stir casting. J Alloys Compd 702:199–208

Figge S, Kröncke H, Hommel D, Epelbaum BM (2009) Temperature dependence of the thermal expansion of AlN. Appl Phys Lett. https://doi.org/10.1063/1.3089568

Acknowledgements

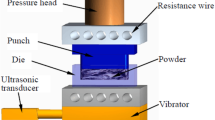

This work was financially supported by the National Key Research and Development Program of China (No. 2022YFB3708400) and the National Natural Science Foundation of China (Nos. 52101180, 51825101, and 52001202). The authors are thankful for the kind help of Li Li at the Teaching Laboratory Center for School of Materials Science and Engineering of Shanghai Jiao Tong University. The authors thank beamline BL14B1 (Shanghai Synchrotron Radiation Facility) for providing the beam time and helps during experiments.

Author information

Authors and Affiliations

Contributions

LG done investigation and writing—original draft. BZ, GZ, and Jie Wang done investigation, writing—review and editing. **gya Wang and LZ contributed to methodology. XZ helped in resources and supervision.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Ethical approval

Not Applicable.

Additional information

Handling Editor: P. Nash.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gu, L., Zhou, B., Zhu, G. et al. Study of the micro-yielding behavior in a SiCp/Mg–Zn–Ca composite using synchrotron radiation diffraction. J Mater Sci 59, 1948–1957 (2024). https://doi.org/10.1007/s10853-023-09236-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-09236-2