Abstract

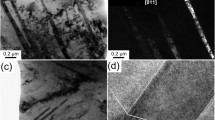

The current research addresses the kink band-assisted grain fragmentation of (CrFeNi)99Si1 medium-entropy alloy during high-pressure torsion (HPT) using combinatorial experimental and crystal plasticity simulations approach. The HPT experiments were carried out at room temperature with a pressure of 6 GPa for 0.2, 0.5, 1, 2, and 5 turns to achieve different levels of shear strain followed by detailed microstructural characterization using electron backscatter diffraction, transmission electron microscopy, and nanoindentation. Microstructural characterization at different length scales shows the fragmentation of grains aided by the formation of kink bands due to the activation of {111} \(<10\overline{1 }>\) and {111} \(<11\overline{2 }>\) slip system followed by gradual conversion of low-angle grain boundaries to high-angle grain boundaries by continuous dynamic recrystallization (cDRX) observed in medium and low stacking fault energy FCC metals and alloys. This aforementioned mechanism occurs over a range of length scales, scaling down the grain size over three orders of magnitude from 40 ± 5 μm to 35 ± 3 nm. Crystal plasticity simulations using the fast Fourier transform solver were employed for full-field simulations to capture the process of kink band-assisted grain fragmentation using the open-source Dusseldorf advanced material simulation kit (DAMASK) software. Finally, constitutive strength equations were developed to quantitatively predict the evolution of strength as a function of HPT deformation to establish the processing-microstructure-mechanical property in (CrFeNi)99Si1 medium-entropy alloy.

Graphical abstract

Similar content being viewed by others

Data availability

Data will be made available on request.

References

Valiev RZ, Islamgaliev RK, Alexandrov IV (2000) Bulk nanostructured materials from severe plastic deformation. Prog Mater Sci 45(2):103–189. https://doi.org/10.1016/S0079-6425(99)00007-9

Lee D-H, Choi I-C, Kawasaki M, Langdon TG, Jang J (2023) A review of recent research on nanoindentation of high-entropy alloys processed by high-pressure torsion. Mater Trans 64(7):1551–1565. https://doi.org/10.2320/matertrans.mt-mf2022015

Gubicza J et al (2019) Evolution of microstructure and hardness in Hf25Nb25Ti25Zr25 high-entropy alloy during high-pressure torsion. J Alloys Compd 788:318–328. https://doi.org/10.1016/j.jallcom.2019.02.220

Zhang X, Godfrey A, Huang X, Hansen N, Liu Q (2011) Microstructure and strengthening mechanisms in cold-drawn pearlitic steel wire. Acta Mater 59(9):3422–3430. https://doi.org/10.1016/j.actamat.2011.02.017

Asghari-Rad P, Nguyen NT-C, Zargaran A, Sathiyamoorthi P, Kim HS (2022) Deformation-induced grain boundary segregation mediated high-strain rate superplasticity in medium entropy alloy. Scr Mater 207:114239. https://doi.org/10.1016/j.scriptamat.2021.114239

Al-Zubaydi ASJ et al (2022) The hot deformation behaviour of laser powder bed fusion deposited Al–Si–Cu alloy processed by high-pressure torsion. J Mater Sci 57(43):20402–20418. https://doi.org/10.1007/s10853-022-07847-9

Adachi N, Todaka Y, Irie K, Umemoto M (2016) Phase transformation kinetics of ω-phase in pure Ti formed by high-pressure torsion. J Mater Sci 51(5):2608–2615. https://doi.org/10.1007/s10853-015-9574-z

Sharma AS, Yadav S, Biswas K, Basu B (2018) High-entropy alloys and metallic nanocomposites: processing challenges, microstructure development and property enhancement. Mater Sci Eng R Reports 131:1–42. https://doi.org/10.1016/j.mser.2018.04.003

Sim RK, Xu Z, Wu MY, He A, Chen DL, Li DY (2022) Microstructure, mechanical properties, corrosion and wear behavior of high-entropy alloy AlCoCrFeNix (x> 0 the) and medium-entropy alloy (x= 0). J Mater Sci 57(25):11949–11968. https://doi.org/10.1007/s10853-022-07256-y

Shahmir H, Tabachnikova E, Podolskiy A, Tikhonovsky M, Langdon TG (2018) Effect of carbon content and annealing on structure and hardness of CrFe2NiMnV0.25 high-entropy alloys processed by high-pressure torsion. J Mater Sci 53(16):11813–11822. https://doi.org/10.1007/s10853-018-2456-4

Edalati P, Mohammadi A, Ketabchi M, Edalati K (2021) Ultrahigh hardness in nanostructured dual-phase high-entropy alloy AlCrFeCoNiNb developed by high-pressure torsion. J Alloys Compd 884:161101. https://doi.org/10.1016/j.jallcom.2021.161101

Praveen S, Bae JW, Asghari-Rad P, Park JM, Kim HS (2018) Ultra-high tensile strength nanocrystalline CoCrNi equi-atomic medium entropy alloy processed by high-pressure torsion. Mater Sci Eng A 735:394–397. https://doi.org/10.1016/j.msea.2018.08.079

Sonkusare R et al (2020) A critical evaluation of microstructure-texture-mechanical behavior heterogeneity in high pressure torsion processed CoCuFeMnNi high entropy alloy. Mater Sci Eng A 782(January):139187. https://doi.org/10.1016/j.msea.2020.139187

Eleti RR, Bhattacharjee T, Zhao L, Bhattacharjee PP, Tsuji N (2018) Hot deformation behavior of CoCrFeMnNi FCC high entropy alloy. Mater Chem Phys 210:176–186. https://doi.org/10.1016/j.matchemphys.2017.06.062

Sonkusare R, Khandelwal N, Ghosh P, Biswas K, Gurao NP (2019) A comparative study on the evolution of microstructure and hardness during monotonic and cyclic high pressure torsion of CoCuFeMnNi high entropy alloy. J Mater Res 34(5):732–743. https://doi.org/10.1557/jmr.2018.479

Azzeddine H, Bradai D, Baudin T, Langdon TG (2022) Texture evolution in high-pressure torsion processing. Prog Mater Sci 125:100886. https://doi.org/10.1016/j.pmatsci.2021.100886

Heczel A, Kawasaki M, Lábár JL, Jang J, Langdon TG, Gubicza J (2017) Defect structure and hardness in nanocrystalline CoCrFeMnNi high-entropy alloy processed by high-pressure torsion. J Alloys Compd 711:143–154. https://doi.org/10.1016/j.jallcom.2017.03.352

Raturi A, Chawake N, Biswas K, Gurao NP (2023) Heterogeneous microstructure in nonequiatomic MoNbTaVW refractory high entropy alloy after high pressure torsion: evolution mechanisms and mechanical properties. Mater Sci Eng A 864(December):144530. https://doi.org/10.1016/j.msea.2022.144530

Gurao NP, Kapoor R, Suwas S (2010) Effect of strain rate on evolution of the deformation microstructure and texture in polycrystalline copper and nickel. Metall Mater Trans A 41(11):2794–2804. https://doi.org/10.1007/s11661-010-0360-x

Tóth LS, Estrin Y, Lapovok R, Gu C (2010) A model of grain fragmentation based on lattice curvature. Acta Mater 58(5):1782–1794. https://doi.org/10.1016/j.actamat.2009.11.020

Beyerlein IJ, Lebensohn RA, Tomé CN (2003) Modeling texture and microstructural evolution in the equal channel angular extrusion process. Mater Sci Eng A 345(1–2):122–138. https://doi.org/10.1016/S0921-5093(02)00457-4

Ostapovets A, Šedá P, Jäger A, Lejček P (2012) New misorientation scheme for a visco-plastic self-consistent model: equal channel angular pressing of magnesium single crystals. Int J Plast 29(1):1–12. https://doi.org/10.1016/j.ijplas.2011.07.006

Arul Kumar M, Mahesh S (2013) Subdivision and microtexture development in f.c.c. grains during plane strain compression. Int J Plast 44:95–110. https://doi.org/10.1016/j.ijplas.2012.12.004

Zecevic M, Lebensohn RA, McCabe RJ, Knezevic M (2018) Modeling of intragranular misorientation and grain fragmentation in polycrystalline materials using the viscoplastic self-consistent formulation. Int J Plast 109(May):193–211. https://doi.org/10.1016/j.ijplas.2018.06.004

Roters F et al (2018) DAMASK—The Düsseldorf advanced material simulation kit for modeling multi-physics crystal plasticity, thermal, and damage phenomena from the single crystal up to the component scale. Comput Mater Sci 158(December):420–478. https://doi.org/10.1016/j.commatsci.2018.04.030

Forest S (1998) Modeling slip, kink and shear banding in classical and generalized single crystal plasticity. Acta Mater 46(9):3265–3281. https://doi.org/10.1016/S1359-6454(98)00012-3

Beausir B, Fundenberger JJ (2017) Analysis tools for electron and X-ray diffraction, ATEX -software. Metz

Kan Q, Yan W, Kang G, Sun Q (2013) Oliver–Pharr indentation method in determining elastic moduli of shape memory alloys—a phase transformable material. J Mech Phys Solids 61(10):2015–2033. https://doi.org/10.1016/j.jmps.2013.05.007

Kumar J, Linda A, Sadhasivam M, Pradeep KG, Gurao NP, Biswas K (2023) The effect of Si addition on the structure and mechanical properties of equiatomic CoCrFeMnNi high entropy alloy by experiment and simulation. Materialia 27:101707. https://doi.org/10.1016/j.mtla.2023.101707

Liu S et al (2020) Effect of silicon addition on the microstructures, mechanical properties and helium irradiation resistance of NiCoCr-based medium-entropy alloys. J Alloys Compd 844:156162. https://doi.org/10.1016/j.jallcom.2020.156162

Reddy TS, Wani IS, Bhattacharjee T, Reddy SR, Saha R, Bhattacharjee PP (2017) Severe plastic deformation driven nanostructure and phase evolution in a Al 0.5 CoCrFeMnNi dual phase high entropy alloy”. Intermetallics 91:150–157

Sakai T, Belyakov A, Kaibyshev R, Miura H, Jonas JJ (2014) Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog Mater Sci 60(1):130–207. https://doi.org/10.1016/j.pmatsci.2013.09.002

Huang K, Logé RE (2016) A review of dynamic recrystallization phenomena in metallic materials. Mater Des 111:548–574. https://doi.org/10.1016/j.matdes.2016.09.012

Gubicza J et al (2019) Influence of severe plastic deformation on the microstructure and hardness of a CoCrFeNi high-entropy alloy: a comparison with CoCrFeNiMn. Mater Charact 154:304–314. https://doi.org/10.1016/j.matchar.2019.06.015

Zhao W et al (2021) Significance of grain refinement on micro-mechanical properties and structures of additively-manufactured CoCrFeNi high-entropy alloy. Mater Sci Eng A 807:140898. https://doi.org/10.1016/j.msea.2021.140898

Suwas S, Mondal S (2019) Texture evolution in severe plastic deformation processes. Mater Trans 60(8):1457–1471. https://doi.org/10.2320/matertrans.MF201933

Naghdy S, Kestens L, Hertelé S, Verleysen P (2016) Evolution of microstructure and texture in commercial pure aluminum subjected to high pressure torsion processing. Mater Charact 120:285–294. https://doi.org/10.1016/j.matchar.2016.09.012

Tazuddin KB, Gurao NP (2016) Deciphering micro-mechanisms of plastic deformation in a novel single phase fcc-based MnFeCoNiCu high entropy alloy using crystallographic texture. Mater Sci Eng A 657:224–233. https://doi.org/10.1016/j.msea.2016.01.065

Yamasaki M, Hagihara K, Inoue S, Hadorn JP, Kawamura Y (2013) Crystallographic classification of kink bands in an extruded Mg–Zn–Y alloy using intragranular misorientation axis analysis. Acta Mater 61:2065–2076

Bian YL et al (2022) Ultrafast severe plastic deformation in high-entropy alloy Al0.1CoCrFeNi via dynamic equal channel angular pressing. Mater Sci Eng A 847:143221. https://doi.org/10.1016/j.msea.2022.143221

Wu G, Chen F, Cui Z, Zhang J (2022) Manufacturing of fine-grained structures by multilevel kinking mechanism through a novel periodic undulating compression method: An example 7075 aluminum alloy. Int J Mach Tools Manuf 182(October):103953. https://doi.org/10.1016/j.ijmachtools.2022.103953

Mohamed FA (2003) A dislocation model for the minimum grain size obtainable by milling. Acta Mater 51(14):4107–4119. https://doi.org/10.1016/S1359-6454(03)00230-1

Zhao YH, Liao XZ, Zhu YT, Horita Z, Langdon TG (2005) Influence of stacking fault energy on nanostructure formation under high pressure torsion. Mater Sci Eng A 410–411:188–193. https://doi.org/10.1016/j.msea.2005.08.074

Zhao YH, Zhu YT, Liao XZ, Horita Z, Langdon TG (2007) Influence of stacking fault energy on the minimum grain size achieved in severe plastic deformation. Mater Sci Eng A 463(1–2):22–26. https://doi.org/10.1016/j.msea.2006.08.119

Kishore K et al (2023) Effect of Si on the evolution of plasticity mechanisms, grain refinement and hardness during high-pressure torsion of a non-equiatomic CoCrMnNi multi-principal element alloy. Int J Plast 169:103720. https://doi.org/10.1016/j.ijplas.2023.103720

Jain R, Kumar M, Biswas K, Gurao NP (2023) Deformation behaviour of the silicon doped metastable Fe50-xMn30Co10Cr10Six complex concentrated alloy using experiments and crystal plasticity simulations. Mater Sci Eng A 885:145620. https://doi.org/10.1016/j.msea.2023.145620

Ashby MF (1970) The deformation of plastically non-homogeneous materials. Philos Mag A J Theor Exp Appl Phys 21(170):399–424. https://doi.org/10.1080/14786437008238426

Hess JB, Barrett CS (1949) Structure and nature of kink bands in zinc. Jom 1(9):599–606. https://doi.org/10.1007/bf03398902

Valiev RZ, Ivanisenko YV, Rauch EF, Baudelet B (1996) Structure and deformaton behaviour of Armco iron subjected to severe plastic deformation. Acta Mater 44(12):4705–4712. https://doi.org/10.1016/S1359-6454(96)00156-5

Wu W et al (2017) Dual mechanisms of grain refinement in a FeCoCrNi high-entropy alloy processed by high-pressure torsion. Sci Rep 7(1):46720. https://doi.org/10.1038/srep46720

Ganji RS, Karthik PS, Rao KBS, Rajulapati KV (2017) Strengthening mechanisms in equiatomic ultrafine grained AlCoCrCuFeNi high-entropy alloy studied by micro- and nanoindentation methods. Acta Mater 125:58–68. https://doi.org/10.1016/j.actamat.2016.11.046

Sriharitha R, Murty BS, Kottada RS (2014) Alloying, thermal stability and strengthening in spark plasma sintered AlxCoCrCuFeNi high entropy alloys. J Alloys Compd 583:419–426

Caillard D, Martin JLBT-PMS (2003), Eds, Chapter 4 - Frictional Forces in Metals, in Thermally Activated Mechanisms in Crystal Plasticity, vol. 8, Pergamon, pp. 85–123 https://doi.org/10.1016/S1470-1804(03)80034-2.

Figueiredo RB, Kawasaki M, Langdon TG (2023) Seventy years of Hall-Petch, ninety years of superplasticity and a generalized approach to the effect of grain size on flow stress. Prog Mater Sci 137:101131. https://doi.org/10.1016/j.pmatsci.2023.101131

Zhao C, Chen X, Pan F, Wang J, Gao S, Tu T, Liu C, Yao J, Atrens A (2019) Strain hardening of as-extruded Mg-xZn (x= 1, 2, 3 and 4 wt%) alloys. J Mater Sci Technol 35(1):142–150

Ogawa Y, Takakuwa O, Tsuzaki K (2023) Solid-solution hardening by hydrogen in Fe–Cr–Ni-based austenitic steel: temperature and strain rate effects. Mater Sci Eng A 879:145281. https://doi.org/10.1016/j.msea.2023.145281

Yang K et al (2023) Recent development of advanced precipitation-strengthened Cu alloys with high strength and conductivity: a review. Prog Mater Sci 138:101141. https://doi.org/10.1016/j.pmatsci.2023.101141

Labusch R (1972) Statistische theorien der mischkristallhärtung. Acta Metall 20(7):917–927. https://doi.org/10.1016/0001-6160(72)90085-5

Zhao YY, Nieh TG (2017) Correlation between lattice distortion and friction stress in Ni-based equiatomic alloys. Intermetallics 86:45–50. https://doi.org/10.1016/j.intermet.2017.03.011

Hughes DA, Lebensohn RA, Wenk HR, Kumar A (2000) Stacking fault energy and microstructure effects on torsion texture evolution. Proc R Soc London Ser A Math Phys Eng Sci 456:921–953

Yao H, Qiao JW, Gao MC, Hawk JA, Ma SG, Zhou H (2016) MoNbTaV medium-entropy alloy. Entropy 18(5):1–15. https://doi.org/10.3390/e18050189

Senkov ON, Scott JM, Senkova SV, Miracle DB, Woodward CF (2011) Microstructure and room temperature properties of a high-entropy TaNbHfZrTi alloy. J Alloys Compd 509(20):6043–6048. https://doi.org/10.1016/j.jallcom.2011.02.171

Acknowledgements

The authors would like to thank Prof. Praveen Kumar, Materials Engineering, Indian Institute of Science, Bangalore, India, for providing access to HPT facility and Mr. Deepak Paliwal for help with the HPT experiments. The authors also acknowledge funding received from the Department of Science and Technology, Government of India, through the Science and Engineering Research Board and the Indian Space Research Organization for research on high-entropy alloys.

Funding

This authors funded by Vikram Sarabhai Space Centre (STC /MET /2019437), DST-SERB (EMR/2016/007831).

Author information

Authors and Affiliations

Contributions

SM was involved in data curation, methodology, formal analysis, conceptualization, writing—original draft. SC contributed to data curation, software, conceptualization, writing—original draft. KB helped in conceptualization, resources, supervision, writing—review & editing. NPG was involved in conceptualization, resources, supervision, writing—review & editing.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

Not applicable.

Additional information

Handling Editor: Megumi Kawasaki.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mahato, S., Chandrakar, S., Biswas, K. et al. An experimental and crystal plasticity simulation study on kink band-assisted grain fragmentation during high-pressure torsion of (CrFeNi)99Si1 medium-entropy alloy. J Mater Sci 59, 6075–6096 (2024). https://doi.org/10.1007/s10853-023-09224-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-09224-6