Abstract

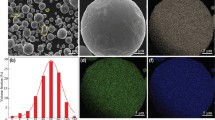

A CoCrCuNiAl0.5 high-entropy alloy (HEA) was prepared by spark plasma sintering (SPS). The effect of plasma transferred arc (PTA) remelting on the microstructures and properties of the SPS-ed HEA was studied. The results showed that, after PTA remelting, the microstructures transformed from randomly-oriented equiaxed grains to dendrites with a directional solidified morphology. The coarse plate-like precipitates (~ 130 nm in diameter and ~ 20 nm in thickness) containing ordered L12 and disordered FCC structures inside the matrix grains were replaced by the disordered FCC spherical Cu-rich precipitates with several nanometers within the dendritic matrix. In the intergranular region, the size of the L12 cubic precipitates was decreased from ~ 55 nm to ~ 2 nm, and dislocations and lattice distortions were also observed. In addition, the brittle B2 phase was disappeared, and the extent of Cu segregation was decreased in the interdendritic region. The SPS-ed sample has a compressive yield strength of 913.8 MPa and a fracture strain of 21.7%. However, the PTA remelted sample exhibits a much higher fracture strain (> 70%, without fracture) and an appreciable yield strength of 739.4 MPa, which indicates an excellent balance between strength and ductility was achieved after PTA remelting. Furthermore, the corrosion resistance of the PTA remelted sample was higher than that of the SPS-ed sample, which was mainly due to the decreased elemental segregation, and the reduced sizes and types of the precipitates.

Graphical abstract

Similar content being viewed by others

References

Yeh JW, Chen SK, Lin SJ, Gan JY, Chin TS, Shun TT, Tsau CH, Chang SY (2004) Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv Eng Mater 6:299–303

Guo Z, Zhang A, Han J, Meng J (2019) Effect of Si additions on microstructure and mechanical properties of refractory NbTaWMo high-entropy alloys. J Mater Sci 54:5844–5851. https://doi.org/10.1007/s10853-018-03280-z

Fu Z, Jiang L, Wardini JL, MacDonald BE, Wen H, **ong W, Zhang D, Zhou Y, Rupert TJ, Chen W, Lavernia EJ (2018) A high-entropy alloy with hierarchical nanoprecipitates and ultrahigh strength. Sci Adv 4(10):8712s

Ding Q, Zhang Y, Chen X, Fu X, Chen D, Chen S, Gu L, Wei F, Bei H, Gao Y, Wen M, Li J, Zhang Z, Zhu T, Ritchie RO, Yu Q (2019) Tuning element distribution, structure and properties by composition in high-entropy alloys. Nature 574(7777):223

Qiu X (2018) Microstructure, hardness and corrosion resistance of Al2CoCrCuFeNiTix high-entropy alloy coatings prepared by rapid solidification. J Alloys Compd 735:359–364

Wang M, Cui H, Zhao Y, Wang C, Wei N, Zhao Y, Zhang X, Song Q (2019) A simple strategy for fabrication of an FCC-based complex concentrated alloy coating with hierarchical nanoprecipitates and enhanced mechanical properties. Mater Des 180:107893

Gludovatz B, Hohenwarter A, Catoor D, Chang EH, George EP, Ritchie RO (2014) A fracture-resistant high-entropy alloy for cryogenic applications. Science 345(6201):1153–1158

Huo W, Fang F, Liu X, Tan S, **e Z, Jiang J (2019) Fatigue resistance of nanotwinned high-entropy alloy films. Mater Sci Eng A 739:26–30

Tang Z, Yuan T, Tsai CW, Yeh JW, Lundin CD, Liaw PK (2015) Fatigue behavior of a wrought Al0.5CoCrCuFeNi two-phase high-entropy alloy. Acta Mater 99:247–258

Senkov ON, Scott JM, Senkova SV, Meisenkothen F, Miracle DB, Woodward CF (2012) Microstructure and elevated temperature properties of a refractory TaNbHfZrTi alloy. J Mater Sci 47:4062–4074. https://doi.org/10.1007/s10853-012-6260-2

Lu Y, Dong Y, Jiang H, Wang Z, Cao Z, Guo S, Wang T, Li T, Liaw PK (2020) Promising properties and future trend of eutectic high entropy alloys. Scr Mater 187:202–209

Wu YD, Cai YH, Wang T, Si JJ, Zhu J, Wang YD, Hui XD (2014) A refractory Hf25Nb25Ti25Zr25 high-entropy alloy with excellent structural stability and tensile properties. Mater Lett 130:277–280

Ye YX, Liu CZ, Wang H, Nieh TG (2018) Friction and wear behavior of a single-phase equiatomic TiZrHfNb high-entropy alloy studied using a nanoscratch technique. Acta Mater 147:78–89

Zhao Y, Cui H, Wang M, Zhao Y, Zhang X, Wang C (2018) The microstructures and properties changes induced by Al: Co ratios of the AlXCrCo2-XFeNi high entropy alloys. Mater Sci Eng A 733:153–163

Yu Y, He F, Qiao Z, Wang Z, Liu W, Yang J (2019) Effects of temperature and microstructure on the triblogical properties of CoCrFeNiNbx eutectic high entropy alloys. J Alloys Compd 775:1376–1385

Qiu Y, Thomas S, Fabijanic D, Barlow AJ, Fraser HL, Birbilis N (2019) Microstructural evolution, electrochemical and corrosion properties of AlxCoCrFeNiTiy high entropy alloys. Mater Des 170:107698

Dai C, Zhao T, Du C, Liu Z, Zhang D (2020) Effect of molybdenum content on the microstructure and corrosion behavior of FeCoCrNiMox high-entropy alloys. J Mater Sci Technol 46:64–73

Torbati-Sarraf H, Shabani M, Jablonski PD, Pataky GJ, Poursaee A (2019) The influence of incorporation of Mn on the pitting corrosion performance of CrFeCoNi high entropy alloy at different temperatures. Mater Des 184:108170

Zhao Y, Wang M, Cui H, Zhao Y, Song X, Zeng Y, Gao X, Lu F, Wang C, Song Q (2019) Effects of Ti-to-Al ratios on the phases, microstructures, mechanical properties, and corrosion resistance of Al2-xCoCrFeNiTix high-entropy alloys. J Alloys Compd 805:585–596

Kulkarni R, Murty BS, Srinivas V (2018) Study of microstructure and magnetic properties of AlNiCo(CuFe) high entropy alloy. J Alloys Compd 746:194–199

Feng XB, Zhang JY, **a ZR, Fu W, Wu K, Liu G, Sun J (2018) Stable nanocrystalline NbMoTaW high entropy alloy thin films with excellent mechanical and electrical properties. Mater Lett 210:84–87

Mishra RK, Shahi RR (2017) Phase evolution and magnetic characteristics of TiFeNiCr and TiFeNiCrM (M = Mn, Co) high entropy alloys. J Magn Magn Mater 442:218–223

Lu C, Niu L, Chen N, ** K, Yang T, **u P, Zhang Y, Gao F, Bei H, Shi S, He MR, Robertson IM, Weber WJ, Wang L (2016) Enhancing radiation tolerance by controlling defect mobility and migration pathways in multicomponent single-phase alloys. Nat Commun 7:13564

El-Atwani O, Li N, Li M, Devaraj A, Baldwin JKS, Schneider MM, Sobieraj D, Wróbel JS, Nguyen-Manh D, Maloy SA, Martinez E (2019) Outstanding radiation resistance of tungsten-based high-entropy alloys. Sci Adv 5:2002

Lu Y, Huang H, Gao X, Ren C, Gao J, Zhang H, Zheng S, ** Q, Zhao Y, Lu C, Wang T, Li T (2019) A promising new class of irradiation tolerant materials: Ti2ZrHfV0.5Mo0.2 high-entropy alloy. J Mater Sci Technol 35:369–373

Zhang A, Han J, Meng J, Su B, Li P (2016) Rapid preparation of AlCoCrFeNi high entropy alloy by spark plasma sintering from elemental powder mixture. Mater Lett 181:82–85

Wang M, Cui H, Zhao Y, Wang C, Wei N, Gao X, Song Q (2019) Enhanced strength and ductility in a spark plasma sintered CoCrCu0.5NiAl0.5 high-entropy alloy via a double-step ball milling approach for processing powders. Mater Sci Eng A 762:138071

Shi P, Ren W, Zheng T, Ren Z, Hou X, Peng J, Hu P, Gao Y, Zhong Y, Liaw PK (2019) Enhanced strength–ductility synergy in ultrafine-grained eutectic high-entropy alloys by inheriting microstructural lamellae. Nat Commun 10:489

Reddy SR, Yoshida S, Bhattacharjee T, Sake N, Lozinko A, Guo S, Bhattacharjee PP, Tsuji N (2019) Nanostructuring with structural-compositional dual heterogeneities enhances strength-ductility synergy in eutectic high entropy alloy. Sci Rep 9:11505

Reddy SR, Sunkari U, Lozinko A, Saha R, Guo S, Bhattacharjee PP (2019) Microstructural design by severe warm-rolling for tuning mechanical properties of AlCoCrFeNi2.1 eutectic high entropy alloy. Intermetallics 114:106601

Schuh B, Mendez-Martin F, Völker B, George EP, Clemens H, Pippan R, Hohenwarter A (2015) Mechanical properties, microstructure and thermal stability of a nanocrystalline CoCrFeMnNi high-entropy alloy after severe plastic deformation. Acta Mater 96:258–268

Tang QH, Huang Y, Huang YY, Liao XZ, Langdon TG, Dai PQ (2015) Hardening of an Al0.3CoCrFeNi high entropy alloy via high-pressure torsion and thermal annealing. Mater Lett 151:126–129

Li P, Sun H, Wang S, Hao X, Dong H (2020) Rotary friction welding of AlCoCrFeNi2.1 eutectic high entropy alloy. J Alloys Compd 814:152322

Kumar N, Komarasamy M, Nelaturu P, Tang Z, Liaw PK, Mishra RS (2015) Friction stir processing of a high entropy alloy Al0.1CoCrFeNi. JOM 67(5):1007–1013

Wei K, Lv M, Zeng X, **ao Z, Huang G, Liu M, Deng J (2019) Effect of laser remelting on deposition quality, residual stress, microstructure, and mechanical property of selective laser melting processed Ti-5Al-2.5Sn alloy. Mater Charact 150:67–77

Chen H, Gu D, Dai D, **a M, Ma C (2018) A novel approach to direct preparation of complete lath martensite microstructure in tool steel by selective laser melting. Mater Lett 227:128–131

Cao H, Dong X, Huang Q, Pan Z, Li J, Fan Z (2014) Effect of scanning speed during PTA remelting treatment on the microstructure and wear resistance of nodular cast iron. Int J Miner Metall Mater 21(4):363–370

Yan M, Zhu WZ (1997a) Surface treatment of 45 steel by plasma-arc melting. Surf Coat Technol 91:183–191

Wang M, Cui H, Wei N, Ding L, Zhang X, Zhao Y, Wang C, Song Q (2018) A new design of in situ Ti(C, N) reinforced composite coatings and their microstructures, interfaces, and wear resistances. ACS Appl Mater Interfaces 10:4250–4265

Yan M, Zhu WZ (1997b) Surface remelting of Ni-Cr-B-Si cladding with a micro-beam plasma arc. Surf Coat Technol 92:157–163

Zhang M, Li M, Chi J, Wang S, Ren L, Fang M (2019) Microstructure and tribology properties of in-situ MC(M:Ti, Nb) coatings prepared via PTA technology. Vacuum 160:264–271

Li Y, Cui X, ** G, Cai Z, Tan N, Lu B, Yang Y, Gao Z, Liu J (2017) Influence of magnetic field on microstructure and properties of TiC/cobalt-based composite plasma cladding coating. Surf Coat Technol 325:555–564

Cheng JB, Xu BS, Liang XB, Wu YX (2008) Microstructure and mechanical characteristics of iron-based coating prepared by plasma transferred arc cladding process. Mater Sci Eng A 492:407–412

Takeuchi A, Inoue A (2005) Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Mater Trans 46(12):2817–2829

Gwalani B, Choudhuri D, Soni V, Ren Y, Styles M, Hwang JY, Nam SJ, Ryu H, Hong SH, Banerjee R (2017) Cu assisted stabilization and nucleation of L12 precipitates in Al0.3CuFeCrNi2 fcc-based high entropy alloy. Acta Mater 129:170–182

Jones NG, Aveson JW, Bhowmik A, Conduit BD, Stone HJ (2014) On the entropic stabilisation of an Al0.5CrFeCoNiCu high entropy alloy. Intermetallics 54:148–153

Jones NG, Christofidou KA, Stone HJ (2015) Rapid precipitation in an Al0.5CrFeCoNiCu high entropy alloy. Mater Sci Technol 31(10):1171–1177

Jones NG, Frezza A, Stone HJ (2014) Phase equilibria of an Al0.5CrFeCoNiCu High Entropy Alloy. Mater Sci Eng A 615:214–221

Pickering EJ, Stone HJ, Jones NG (2015) Fine-scale precipitation in the high-entropy alloy Al0.5CrFeCoNiCu. Mater Sci Eng A 645:65–71

Tsai MH, Yuan Y, Cheng G, Xu W, Tsai KY, Tsai CW, Jian WW, Juan CC, Shen WJ, Chuang MH, Yeh JW, Zhu YT (2013) Morphology, structure and composition of precipitates in Al0.3CoCrCu0.5FeNi high-entropy alloy. Intermetallics 32:329–336

Miao J, Pollock TM, Wayne Jones J (2009) Crystallographic fatigue crack initiation in nickel-based superalloy René 88DT at elevated temperature. Acta Mater 57:5964–5974

Cui CY, Gu YF, Harada H, ** DH, Sato A (2006) Microstructural evolution and mechanical properties of a Ni-based superalloy TMW-4. Metall Mater Trans A 37:3183–3190

Jones NG, Izzo R, Mignanelli PM, Christofidou KA, Stone HJ (2016) Phase evolution in an Al0.5CrFeCoNiCu High Entropy Alloy. Intermetallics 71:43–50

Li W, Liu P, Liaw PK (2018) Microstructures and properties of high-entropy alloy films and coatings: a review. Mater Res Lett 6(4):199–229

An Z, Jia H, Wu Y, Rack PD, Patchen AD, Liu Y, Ren Y, Li N, Liaw PK (2015) Solid-solution CrCoCuFeNi high-entropy alloy thin films synthesized by sputter deposition. Mater Res Lett 3:203–209

Katakam S, Joshi SS, Mridha S, Mukherjee S, Dahotre NB (2014) Laser assisted high entropy alloy coating on aluminum: microstructural evolution. J Appl Phys 116:104906

He JY, Wang H, Huang HL, Xu XD, Chen MW, Wu Y, Liu XJ, Nieh TG, An K, Lu ZP (2016) A precipitation-hardened high-entropy alloy with outstanding tensile properties. Acta Mater 102:187–196

Ganji RS, Sai Karthik P, Sankara Rao Bhanu K, Rajulapati KV (2017) Strengthening mechanisms in equiatomic ultrafine grained AlCoCrCuFeNi high-entropy alloy studied by micro- and nanoindentation methods. Acta Mater 125:58–68

Sriharitha R, Murty BS, Kottada RS (2014) Alloying, thermal stability and strengthening in spark plasma sintered AlxCoCrCuFeNi high entropy alloys. J Alloys Compd 583:419–426

He JY, Liu WH, Wang H, Wu Y, Liu XJ, Nieh TG, Lu ZP (2014) Effects of Al addition on structural evolution and tensile properties of the FeCoNiCrMn high-entropy alloy system. Acta Mater 62:105–113

Fu Z, Chen W, Wen H, Zhang D, Chen Z, Zheng B, Zhou Y, Lavernia EJ (2016) Microstructure and strengthening mechanisms in an FCC structured single-phase nanocrystalline Co25Ni25Fe25Al7.5Cu17.5 high-entropy alloy. Acta Mater 107:59–71

Liu WH, Wu Y, He JY, Nieh TG, Lu ZP (2013) Grain growth and the Hall-Petch relationship in a high-entropy FeCrNiCoMn alloy. Scr Mater 68:526–529

Williamson GK, Hall WH (1953) X-ray line broadening from filed Al and W. Acta Metall 1:22–31

Nie JF, Muddle BC (2008) Strengthening of an Al–Cu–Sn alloy by deformation-resistant precipitate plates. Acta Mater 56(14):3490–3501

Wang ZG, Zhou W, Fu LM, Wang JF, Luo RC, Han XC, Chen B, Wang XD (2017) Effect of coherent L12 nanoprecipitates on the tensile behavior of a fcc-based high-entropy alloy. Mater Sci Eng A 696:503–510

Booth-Morrison C, Dunand DC, Seidman DN (2011) Coarsening resistance at 400 °C of precipitation-strengthened Al–Zr–Sc–Er alloys. Acta Mater 59:7029–7042

Wen H, Top** TD, Isheim D, Seidman DN, Lavernia EJ (2013) Strengthening mechanisms in a high-strength bulk nanostructured Cu–Zn–Al alloy processed via cryomilling and spark plasma sintering. Acta Mater 61(8):2769–2782

Pollock TM, Argon AS (1992) Creep resistance of CMSX-3 nickel base superalloy single crystals. Acta Metall Mater 40(1):1–30

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Nos. 51822402, 51671044, 51772176, 51971121, and 52001051), the National Key Research and Development Program of China (Nos.2019YFA0209901 and 2018YFA0702901), the fund of the State Key Laboratory of Solidification Processing in NWPU (Grant No. SKLSP201902), the Liao Ning Revitalization Talents Program (XLYC1807047), the National MCF Energy R&D Program (project No. 2018YFE0312400), the Fund of Science and Technology on Reactor Fuel and Materials Laboratory (STRFML-2020-04), the Taishan Scholarship of Climbing Plan (No. tspd20161006), and the China Postdoctoral Science Foundation (No. 2020M670747).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Handling Editor: Sophie Primig.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, M., Zhang, G., Cui, H. et al. Effect of plasma remelting on microstructure and properties of a CoCrCuNiAl0.5 high-entropy alloy prepared by spark plasma sintering. J Mater Sci 56, 5878–5898 (2021). https://doi.org/10.1007/s10853-020-05570-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05570-x