Abstract

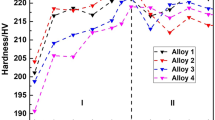

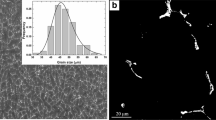

The relationship between microstructure evolution and mechanical performance of Al–Zn–Mg–Cu alloys with varying Cu/Mg ratios was discussed in detail under different two-step aging (T7X). The results showed that the undissolved second-phase particles including σ-Al7Cu2Fe and T-Al2Mg3Zn occurred in the quenched Al–Zn–Mg–Cu alloys. When the Cu/Mg ratio approaches 1.64, the S-Al2CuMg phase was also observed. Although the Cu/Mg ratio did not change the precipitation sequence of the Al–Zn–Mg–Cu alloys, it changed the coarsening rate and precipitate size distribution during aging process. The Al–Zn–Mg–Cu alloy with the lowest Cu/Mg ratio has the slowest coarsening rate and the highest strength (655 MPa). The fracture morphology of Al–Zn–Mg–Cu alloys changes from the typical brittle fracture to the intergranular-dominated mixed fracture mode or ductile fracture when the Cu/Mg ratios increases. Besides, the T79-aged alloys with varying Cu/Mg ratios have similar grain boundary precipitates (GBPs) and precipitate-free zones (PFZs). The T74-aged alloys with higher Cu/Mg ratio have more coarser GBPs and wider PFZs.

Similar content being viewed by others

References

Azarniya A, Taheri AK, Taheri KK (2019) Recent advances in ageing of 7xxx series aluminum alloys: a physical metallurgy perspective. J Alloys Comp 781:945–983

Rometsch PA, Zhang Y, Knight S (2014) Heat treatment of 7xxx series aluminum alloys-some recent developments. Trans Nonferrous Met Soc China 24:2003–2017

Chen SY, Chen KH, Dong PX, Ye SP (2013) Lan** Huang, effect of recrystallization and heat treatment on strength and SCC of an Al-Zn-Mg-Cu alloy. J Alloys Comp 581:705–709

Huang K, Marthinsen K, Zhao QL, Loge RE (2018) The double-edge effect of second-phase particles on the recrystallization behaviour and associated mechanical properties of metallic materials. Pro Mater Sci 92:284–359

Dumont D, Deschamps A, Brechet Y (2003) On the relationship between microstructure, strength and toughness in AA7050 aluminum alloy. Mater Sci Eng A 356:326–336

Peng XY, Li Y, Liang XP, Guo Q, Xu GF, Peng YY (2018) Precipitate behavior and mechanical properties of enhanced solution treated Al-Zn-Mg-Cu alloy during non-isothermal ageing. J Alloys Comp 735:964–974

Xu XS, Zheng JX, Li Z, Luo RC, Chen B (2017) Precipitation in an Al-Zn-Mg-Cu alloy during isothermal aging: atomic-scale HAADF-STEM investigation. Mater Sci Eng A 691:60–70

Fan X, Jiang D, Meng Q, Lai Z, Zhang X (2006) Characterization of precipitation microstructure and properties of 7150 aluminum alloy. Mater Sci Eng A 427:130–135

Cao FH, Zheng JX, Jiang Y, Chen B, Wang YR, Hu T (2019) Experimental and DFT characterization of η’ nano-phase and its interfaces in Al-Zn-Mg-Cu alloys. Acta Mater 164:207–219

BergJØnnesHansewLiKnutsonWaterlooSchryversWallenberg LKJGVXZMGDLR (2001) GP-zones in Al-Zn-Mg alloys and their role in artificial ageing. Acta Mater. https://doi.org/10.1016/S1359-6454(01)00251-8

Wolverton C (2001) Crystal structure and stability of complex precipitate phases in Al-Cu-Mg-(Si) and Al-Zn-Mg alloy. Acta Mater 49:3129–3142

Mondal C, Mukhopadhyay AK (2005) On the nature of T (Al2Mg3Zn3) and S (Al2CuMg) phases present in as-cast and annealed 7055 aluminum alloy. Mater Sci Eng A 391:367–376

Shu WX, Hou LG, Zhang C, Liu JC, Zhuang LZ, Zhang JS (2016) Tailored Mg and Cu contents affecting the microstructures and mechanical properties of high-strength Al-Zn-Mg-Cu alloys. Mater Sci Eng A 657:269–283

Dong PX, Chen SY, Chen KH (2019) Effects of Cu content on microstructure and properties of super-high-strength Al-9.3Zn-2.4Mg-xCu-Zr alloy. J Alloys Comp. 788:329–337

Peng GS, Chen KH, Fang HC, Chen SY (2019) Effect of Cr and Yb additions on microstructure and properties of low copper Al-Zn-Mg-Cu alloy. Mater Des 164:107558

Chinh NQ, Lendvai J, ** DH, Hono K (2004) The effect of Cu on mechanical and precipitation properties of Al-Zn-Mg alloys. J Alloys Comp 378:52–60

Marlaud T, Deschamps A, Bley F, Lefebvre W, Baroux B (2010) Influence of alloy composition and heat treatment on precipitate in Al-Zn-Mg-Cu alloys. Acta Mater 58:248–260

Liao YG, Han XQ, Zeng MX, ** M (2015) Influence of Cu on microstructure and tensile properties of 7XXX series aluminum alloy. Mater Des 66:581–586

Wu XZ, **ao DH, Zhu ZM, Li XX, Chen KH (2014) Effects of Cu/Mg ratio on microstructure and properties of AA7085 alloys. Trans Nonferrous Metals Soc China 24:2054–2060

Nes E (1972) Precipitation of the metastable cubic Al3Zr-phase in sub-peritectic Al-Zr alloys. Acta Metall 20(4):499–506

Sha G, Cerezo A (2004) Early-stage precipitation in Al-Zn-Mg-Cu alloy (7050). Acta Mater. 52(45):3–4516

WenFanWang**LiLiZhang **ong KYQGJLBXWZHYGBQ (2016) Aging behavior and precipitate characterization of a high Zn-containing Al-Zn-Mg-Cu with various tempers. Mater Des 101:16–23

Wen K, **ong BQ, Zhang YG, Li ZH, Li XW, Huang SH, Yan LZ (2018) Over-aging influenced matrix precipitate characteristics improve fatigue crack propagation in a high Zn-containing Al-Zn-Mg-Cu alloy. Mater Sci Eng A 716:42–54

Bakker H, Bonzel HP, Bruff CM, Dayananda MA, Gust W, Horvth J (1990) Diffusion in solid metals and alloys. Springer Verlag, Berlin

Zhao H, Geuser FD, Silva AKD, Szczepaniak A, Gault B, Ponge D, Raabe D (2018) Segregation assisted grain boundary precipitation in a model Al-Zn-Mg-Cu alloy. Acta Mater 156:318–329

Marlaud T, Malki B, Henon C, Deschamps A, Baroux B (2011) Relationship between alloy composition, microstructure and exfoliation corrosion in Al-Zn-Mg-Cu alloys. Corros Sci 53:3139–3149

Kairy SK, Turk S, Birbilis N, Shekhter A (2018) The role of microstructure and microchemistry on intergranular corrosion of aluminium alloy AA7085-T7452. Corros Sci 143:414–427

Dai P, Luo X, Yang YQ, Kou ZD, Huang B, Zang JX, Ru JG (2019) Thermal stability analysis of a lightweight Al-Zn-Mg-Cu alloy by TEM and tensile tests. Mater Charact 153:271–283

Lang P, Wojcik T, Povoden-Karadeniz E, Falahati A, Kozeschnik E (2014) Thermo-Kinetic prediction of metastale and stable phase precipitation in Al-Zn-Mg series aluminum alloys during non-isothermal DSC analysis. J Alloys Comp 609:129–136

Ghosh A, Ghosh M, Shankar G (2018) On the role of precipitates in controlling microstructure and mechanical properties of Ag and Sn added 7075 alloys during artificial ageing. Mater Sci Eng A 738:399–411

Jiang XJ, Noble B, Holme B, Waterloo G, Tafto J (2000) Differential scanning calorimetry and electron diffraction investigation on low-temperature ageing in Al-Zn-Mg alloys. Metall Mater Trans A 31:339–348

Wang XD, Pan QL, Liu LL, **ong SW, Wang WY, Lai JP, Wei YW, Huang ZQ (2018) Characterization of hot extrusion and heat treatment on mechanical properties in spray formed ultra-high strength Al-Zn-Mg-Cu alloy. Mater Charact 144:131–140

Deschamps A, Livet F, Bréchet Y (1999) Influence of precipitation on ageing in an Al-Zn-Mg alloy-I. microstructure evolution and mechanical properties. Acta Mater 47:281–292

Zuo JR, Hou LG, Shi JT, Cui H, Zhuang LZ, Zhang JS (2017) The mechanism of grain refinement and plasticity enhancement by an improved thermomechanical treatment of 7055 Al alloy. Mater Sci Eng A 702:42–52

Ghiaasiaan R, Shankar S (2018) Structure-property models in Al-Zn-Mg-Cu alloys: a critical experimental assessment of shape castings. Mater Sci Eng A 733:235–245

Starink MJ, Wang SC (2003) A model for the yield strength of overaged Al-Zn-Mg-Cu alloys. Acta Mater 51:5153–5150

Godard D, Archambault P, Aeby-Gautier E, Lapasset G (2002) Precipitation sequences during quenching of the AA 7010 alloy. Acta Mater 50:2319–2329

Li B, Wang XM, Chen H, Hu J, Gou GQ (2016) Influence of heat treatment on the strength and fracture toughness of 7N01 aluminum alloy. J Alloys Compd 678:160–166

Dai P, Luo X, Yang YQ, Kou ZD, Huang B, Wang C, Zang JX, Ru JG (2018) Nano-Scale precipitate evolution and mechanical properties of 7085 aluminum alloy during thermal exposure. Mater Sci Eng A 729:411–422

Leng L, Zhang ZJ, Duan QQ, Zhang P, Zhang ZF (2018) Improving the fatigue strength of 7075 alloy through aging. Mater Sci Eng A 738:24–30

Deschamps A, Decreus B, De Geuser F, Dorin T, Weyland M (2013) The influence of precipitation on plastic deformation of Al-Cu-Li alloys. Acta Mater 61:4010–4021

Han NM, Zhang XM, Liu SD, He DG, Zhang R (2011) Effect of solution treatment on the strength and fracture toughness of aluminum alloy 7050. J Alloys Compd 509:4138–4145

Gronsky R, Furrer P (1981) Grain boundary precipitation in aluminum alloys: effect of boundary structure. Metall Mater Trans A 12A:121–127

Acknowledgements

This work was supported by the Chinese National Pre-research Project [No.41423040204] and the Hunan Science and Technology Program of China [No.2017GK2261].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no conflict of interests.

Additional information

Handling Editor: P. Nash.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wei, S., Wang, R., Zhang, H. et al. Influence of Cu/Mg ratio on microstructure and mechanical properties of Al–Zn–Mg–Cu alloys. J Mater Sci 56, 3472–3487 (2021). https://doi.org/10.1007/s10853-020-05438-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05438-0