Abstract

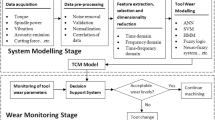

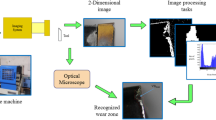

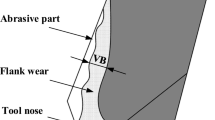

In the era of Industry 4.0, cloud computing has attracted a lot of attention from industrial organizations in realizing smart manufacturing. However, considering the latency issue of cloud computing, the time-sensitive data are more suitable to be processed through edge computing close to the data source, which has been recognized as a potential solution to enable the real-time monitoring in the machining industry, especially for the small and medium-sized manufacturers. Due to the limitations of available data and computing capability at the edge location, it is still very challenging to realize edge computing for complex machining monitoring. To satisfy this research need, a calibration-based tool condition monitoring (TCM) is developed to monitor the tool wear progression in repetitive machining processes by comparing the characteristic signals generated by the reference cutting tools in the calibration procedure with the signal generated by the cutting tool being monitored through a concise similarity analysis. The proposed algorithm can be easily integrated into typical cyber-psychical systems to realize the edge computing in a very efficient and flexible way. To validate the performance of the proposed algorithm, a case study is demonstrated for tool wear monitoring of repetitive milling processes. Experimental validation has shown that the proposed calibration-based TCM algorithm can effectively realize the edge computing in tool wear monitoring through a simple calculation.

Similar content being viewed by others

References

Zhong, R. Y., Xu, X., Klotz, E., & Newman, S. T. (2017). Intelligent Manufacturing in the Context of Industry 4.0: A Review, Engineering, 3, 616–630. doi:https://doi.org/10.1016/J.ENG.2017.05.015

Lee, J., Bagheri, B., & Kao, H. A. (2015). A Cyber-Physical Systems architecture for Industry 4.0-based manufacturing systems. Manuf. Lett, 3, 18–23. doi:https://doi.org/10.1016/j.mfglet.2014.12.001

Bi, Z., Da Xu, L., & Wang, C. (2014). Internet of things for enterprise systems of modern manufacturing. IEEE Trans. Ind. Informatics, 10, 1537–1546. doi:https://doi.org/10.1109/TII.2014.2300338

Schröder, C. (2016). The challenges of industry 4.0 for small and medium-sized enterprises. Ger: Friedrich-Ebert-Stiftung Bonn

Lee, J., Ardakani, H. D., Yang, S., & Bagheri, B. (2015). Industrial Big Data Analytics and Cyber-physical Systems for Future Maintenance & Service Innovation. Procedia CIRP, 38, 3–7. doi:https://doi.org/10.1016/j.procir.2015.08.026

Yao, X., Zhou, J., Lin, Y., Li, Y., Yu, H., & Liu, Y. (2019). Smart manufacturing based on cyber-physical systems and beyond. J. Intell. Manuf, 30, 2805–2817

Wang, J., Zhang, L., Duan, L., & Gao, R. X. (2017). A new paradigm of cloud-based predictive maintenance for intelligent manufacturing. J. Intell. Manuf, 28, 1125–1137. doi:https://doi.org/10.1007/s10845-015-1066-0

Wang, P., Gao, R. X., & Fan, Z. (2015). Cloud Computing for Cloud Manufacturing: Benefits and Limitations. J. Manuf. Sci. Eng. Trans. ASME, 137(4). doi:https://doi.org/10.1115/1.4030209

Pizoń, J., & Lipski, J. (2016). Perspectives for fog computing in manufacturing. Appl. Comput. Sci. 12

Liu, Y., Zhang, Y., & Wu, J. (2019). The Proceedings of the 2018 Asia-Pacific International Symposium on Aerospace Technology (APISAT 2018), Springer Singapore, doi:https://doi.org/10.1007/978-981-13-3305-7

Yousefpour, A., Fung, C., Nguyen, T., Kadiyala, K., Jalali, F., Niakanlahiji, A. … Jue, J. P. (2019). All one needs to know about fog computing and related edge computing paradigms: A complete survey. J. Syst. Archit, 98, 289–330. doi:https://doi.org/10.1016/j.sysarc.2019.02.009

Kunal, S., Saha, A., & Amin, R. (2019). An overview of cloud-fog computing: Architectures, applications with security challenges. Secur. Priv, 2, e72

Satyanarayanan, M. (2017). The emergence of edge computing. Computer (Long. Beach. Calif), 50, 30–39. doi:https://doi.org/10.1109/MC.2017.9

Syafrudin, M., Fitriyani, N. L., Alfian, G., & Rhee, J. (2019). An affordable fast early warning system for edge computing in assembly line. Appl. Sci, 9(1), 84. doi:https://doi.org/10.3390/app9010084

O’Donovan, P., Gallagher, C., Bruton, K., & O’Sullivan, D. T. J. (2018). A fog computing industrial cyber-physical system for embedded low-latency machine learning Industry 4.0 applications. Manuf. Lett, 15, 139–142. doi:https://doi.org/10.1016/j.mfglet.2018.01.005

Li, X., Wan, J., Dai, H. N., Imran, M., **a, M., & Celesti, A. (2019). A Hybrid Computing Solution and Resource Scheduling Strategy for Edge Computing in Smart Manufacturing. IEEE Trans. Ind. Informatics, 15, 4225–4234. doi:https://doi.org/10.1109/TII.2019.2899679

Dao, N. N., Lee, Y., Cho, S., Kim, E., Chung, K. S., & Keum, C. (2017). Multi-tier multi-access edge computing: The role for the fourth industrial revolution, Int. Conf. Inf. Commun. Technol. Converg. ICT Converg. Technol. Lead. Fourth Ind. Revolution, ICTC 2017. 2017-Decem, 1280–1282. doi:https://doi.org/10.1109/ICTC.2017.8190921

Wu, D., Liu, S., Zhang, L., Terpenny, J., Gao, R. X., Kurfess, T., & Guzzo, J. A. (2017). A fog computing-based framework for process monitoring and prognosis in cyber-manufacturing. J. Manuf. Syst, 43, 25–34. doi:https://doi.org/10.1016/j.jmsy.2017.02.011

Dao, N. N., Vu, D. N., Lee, Y., Cho, S., Cho, C., & Kim, H. (2018 (2018)). Pattern-identified online task scheduling in multitier edge computing for industrial iot services, Mob. Inf. Syst. doi:https://doi.org/10.1155/2018/2101206

Park, D., Kim, S., An, Y., Jung, J. Y., & Lired (2018). A light-weight real-time fault detection system for edge computing using LSTM recurrent neural networks. Sensors (Switzerland), 18(7), 2110. doi:https://doi.org/10.3390/s18072110

Liang, Y. C., Li, W. D., Lu, X., & Wang, S. (2019). Fog computing and convolutional neural network enabled prognosis for machining process optimization. J. Manuf. Syst, 52, 32–42. doi:https://doi.org/10.1016/j.jmsy.2019.05.003

Li, L., Ota, K., & Dong, M. (2018). Deep Learning for Smart Industry: Efficient Manufacture Inspection System with Fog Computing. IEEE Trans. Ind. Informatics, 14, 4665–4673. doi:https://doi.org/10.1109/TII.2018.2842821

Peralta, G., Iglesias-Urkia, M., Barcelo, M., Gomez, R., Moran, A., & Bilbao, J. (2017). Fog computing based efficient IoT scheme for the Industry 4.0, Proc. IEEE Int. Work. Electron. Control. Meas. Signals Their Appl. to Mechatronics, ECMSM 2017. (2017) 1–6. doi:https://doi.org/10.1109/ECMSM.2017.7945879

Kothuru, A., Nooka, S. P., & Liu, R. (2018). Application of audible sound signals for tool wear monitoring using machine learning techniques in end milling. Int. J. Adv. Manuf. Technol, 95, 3797–3808. doi:https://doi.org/10.1007/s00170-017-1460-1

Kothuru, A., Nooka, S. P., & Liu, R. (2018). Audio-Based Tool Condition Monitoring in Milling of the Workpiece Material With the Hardness Variation Using Support Vector Machines and Convolutional Neural Networks. J. Manuf. Sci. Eng. Trans. ASME, 140, 1–9. doi:https://doi.org/10.1115/1.4040874

Kothuru, A., Nooka, S. P., & Liu, R. (2019). Application of deep visualization in CNN-based tool condition monitoring for end milling. Procedia Manuf, 34, 995–1004. doi:https://doi.org/10.1016/j.promfg.2019.06.096

Li, Z., Liu, R., & Wu, D. (2019). Data-driven smart manufacturing: Tool wear monitoring with audio signals and machine learning. J. Manuf. Process, 48, 66–76. doi:https://doi.org/10.1016/j.jmapro.2019.10.020

Chen, C. H., Lin, M. Y., & Liu, C. C. (2018). Edge Computing Gateway of the Industrial Internet of Things Using Multiple Collaborative Microcontrollers. IEEE Netw, 32, 24–32. doi:https://doi.org/10.1109/MNET.2018.1700146

Chen, B., Wan, J., Celesti, A., Li, D., Abbas, H., & Zhang, Q. (2018). Edge Computing in IoT-Based Manufacturing. IEEE Commun. Mag, 56, 103–109. doi:https://doi.org/10.1109/MCOM.2018.1701231

Mocanu, S., Geampalia, G., Chenaru, O., & Dobrescu, R. (2018). Fog-based solution for real-time monitoring and data processing in manufacturing, 2018 22nd Int. Conf. Syst. Theory, Control Comput. ICSTCC - Proc. (2018) 504–509. doi:https://doi.org/10.1109/ICSTCC.2018.8540783

Dupont, C., Giaffreda, R., & Capra, L. (2017). Edge computing in IoT context: Horizontal and vertical Linux container migration, GIoTS 2017 - Glob. Internet Things Summit, Proc. 2–5. doi:https://doi.org/10.1109/GIOTS.2017.8016218

Li, Z., Wang, W. M., Liu, G., Liu, L., He, J., & Huang, G. Q. (2018). Toward open manufacturing a cross-enterprises knowledge and services exchange framework based on blockchain and edge computing. Ind. Manag. Data Syst, 118, 303–320. doi:https://doi.org/10.1108/IMDS-04-2017-0142

Helu, M., & Weiss, B. (2016). The current state of sensing, health management, and control for small-to-medium-sized manufacturers, ASME 2016 11th Int. Manuf. Sci. Eng. Conf. MSEC, 2, 1–18. doi:https://doi.org/10.1115/MSEC2016-8783

Chai, X., Hou, B., Zou, P., Zeng, J., & Zhou, J. (2018). INDICS: An industrial internet platform, Proc. – 2018 IEEE SmartWorld, Ubiquitous Intell. Comput. Adv. Trust. Comput. Scalable Comput. Commun. Cloud Big Data Comput. Internet People Smart City Innov. SmartWorld/UIC/ATC/ScalCom/CBDCo. 1824–1828. doi:https://doi.org/10.1109/SmartWorld.2018.00307

Agarwal, N., & Brem, A. (2015). Strategic business transformation through technology convergence: Implications from General Electric’s industrial internet initiative. Int. J. Technol. Manag, 67, 196–214. doi:https://doi.org/10.1504/IJTM.2015.068224

Nelson, R. (2017). Smart factories leverage cloud, edge computing - Evaluation Engineering. Evaluationengineering.Com, 56, 14–17

Liu, R. (2020). A novel edge computing based architecture for intelligent tool condition monitoring, in: Proc. ASME 2020 15th Int. Manuf. Sci. Eng. Conf., Cincinnati, OH, USA,

Yan, D., Ding, X., Pan, S., & Huang, H. (2021). Tool Wear Prediction Based on Edge Data Processing and Deep Learning Model, in:J. Phys. Conf. Ser., : p.12165

Huang, H., Yang, L., Wang, Y., Xu, X., & Lu, Y. (2021). Digital Twin-driven online anomaly detection for an automation system based on edge intelligence. J. Manuf. Syst, 59, 138–150

Liu, R., Kothuru, A., & Zhang, S. (2020). Calibration-based tool condition monitoring for repetitive machining operations. J. Manuf. Syst, 54, 285–293. doi:https://doi.org/10.1016/j.jmsy.2020.01.005

I.S.O. ISO, 8688-2: 1989_Tool life testing in milling—Part 2: End milling, Int. Organ. Stand. (n.d.)

Machinery’s, & Handbook (2016). 30th ed.,Industrial Press, Inc.,

Acknowledgements

None declared.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, R. An edge-based algorithm for tool wear monitoring in repetitive milling processes. J Intell Manuf 34, 2333–2343 (2023). https://doi.org/10.1007/s10845-022-01925-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-022-01925-0