Abstract

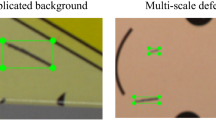

Similar and indeterminate defect detection of solar cell surface with heterogeneous texture and complex background is a challenge of solar cell manufacturing. The traditional manufacturing process relies on human eye detection which requires a large number of workers without a stable and good detection effect. In order to solve the problem, a visual defect detection method based on multi-spectral deep convolutional neural network (CNN) is designed in this paper. Firstly, a selected CNN model is established. By adjusting the depth and width of the model, the influence of model depth and kernel size on the recognition result is evaluated. The optimal CNN model structure is selected. Secondly, the light spectrum features of solar cell color image are analyzed. It is found that a variety of defects exhibited different distinguishable characteristics in different spectral bands. Thus, a multi-spectral CNN model is constructed to enhance the discrimination ability of the model to distinguish between complex texture background features and defect features. Finally, some experimental results and K-fold cross validation show that the multi-spectral deep CNN model can effectively detect the solar cell surface defects with higher accuracy and greater adaptability. The accuracy of defect recognition reaches 94.30%. Applying such an algorithm can increase the efficiency of solar cell manufacturing and make the manufacturing process smarter.

Similar content being viewed by others

References

Agarwal, K., & Shivpuri, R. (2015). On line prediction of surface defects in hot bar rolling based on Bayesian hierarchical modeling. Journal of Intelligent Manufacturing,26(4), 785–800.

Anwar, S. A., & Abdullah, M. Z. (2014). Micro-crack detection of multi crystalline solar cells featuring an improved anisotropic diffusion filter and image segmentation technique. EURASIP Journal on Image and Video Processing,2014(1), 15.

Belouchrani, A., Abed-Meraim, K., Cardoso, J. F., & Moulines, E. (1997). A blind source separation technique using second-order statistics. IEEE Transactions on Signal Processing,45(2), 434–444.

Bianconi, F., González, E., Fernández, A., & Saetta, S. A. (2012). Automatic classification of granite tiles through colour and texture features. Expert Systems with Applications,39(12), 11212–11218.

Bulnes, F. G., Usamentiaga, R., Garcia, D. F., & Molleda, J. (2016). An efficient method for defect detection during the manufacturing of web materials. Journal of Intelligent Manufacturing,27(2), 431–445.

Çaydaş, U., & Ekici, S. (2012). Support vector machines models for surface roughness prediction in CNC turning of AISI 304 austenitic stainless steel. Journal of Intelligent Manufacturing,23(3), 639–650.

Chen, F. C., & Jahanshahi, M. R. (2018). NB-CNN: Deep learning-based crack detection using convolutional neural network and naive Bayes data fusion. IEEE Transactions on Industrial Electronics,65(5), 4392–4400.

Chen, S. H., & Perng, D. B. (2016). Automatic optical inspection system for IC molding surface. Journal of Intelligent Manufacturing,27, 1–12.

Chiou, Y. C., Liu, J. Z., & Liang, Y. T. (2011). Micro crack detection of multi-crystalline silicon solar wafer using machine vision techniques. Sensor Review,31(2), 154–165.

Deitsch, S., Christlein, V., Berger, S., Buerhop-Lutz, C., Maier, A., Gallwitz, F., et al. (2018). Automatic classification of defective photovoltaic module cells in electroluminescence images. ar**v preprint ar**v:1807.02894.

Ghorai, S., Mukherjee, A., Gangadaran, M., & Dutta, P. K. (2013). Automatic defect detection on hot-rolled flat steel products. IEEE Transactions on Instrumentation and Measurement,62(3), 612–621.

Glorot, X., Bordes, A., & Bengio, Y. (2011, June). Deep sparse rectifier neural networks. In Proceedings of the fourteenth international conference on artificial intelligence and statistics (pp. 315–323).

Jeguirim, S. E. G., Dhouib, A. B., Sahnoun, M., Cheikhrouhou, M., Schacher, L., & Adolphe, D. (2011). The use of fuzzy logic and neural networks models for sensory properties prediction from process and structure parameters of knitted fabrics. Journal of Intelligent Manufacturing,22(6), 873–884.

Jian, C., Gao, J., & Ao, Y. (2017). Automatic surface defect detection for mobile phone screen glass based on machine vision. Applied Soft Computing,52, 348–358.

Kang, S. (2018). Joint modeling of classification and regression for improving faulty wafer detection in semiconductor manufacturing. Journal of Intelligent Manufacturing. https://doi.org/10.1007/s10845-018-1447-2.

Kim, S., Kim, W., Noh, Y. K., & Park, F. C. (2017). Transfer learning for automated optical inspection. In 2017 International Joint Conference on Neural Networks (IJCNN) (pp. 2517–2524). IEEE.

Kumar, S. S., Abraham, D. M., Jahanshahi, M. R., Iseley, T., & Starr, J. (2018). Automated defect classification in sewer closed circuit television inspections using deep convolutional neural networks. Automation in Construction,91, 273–283.

Latif-Amet, A., Ertüzün, A., & Erçil, A. (2000). An efficient method for texture defect detection: Sub-band domain co-occurrence matrices. Image and Vision Computing,18(6–7), 543–553.

Li, W. C., & Tsai, D. M. (2012). Wavelet-based defect detection in solar wafer images with inhomogeneous texture. Pattern Recognition,45(2), 742–756.

Liao, S., Law, M. W., & Chung, A. C. (2009). Dominant local binary patterns for texture classification. IEEE Transactions on Image Processing,18(5), 1107–1118.

Lin, H., Li, B., Wang, X., Shu, Y., & Niu, S. (2018). Automated defect inspection of LED chip using deep convolutional neural network. Journal of Intelligent Manufacturing. https://doi.org/10.1007/s10845-018-1415-x.

Liu, A., Lin, W., Paul, M., Deng, C., & Zhang, F. (2010). Just noticeable difference for images with decomposition model for separating edge and textured regions. IEEE Transactions on Circuits and Systems for Video Technology,20(11), 1648–1652.

Mirmehdi, M. (2008). Handbook of texture analysis. London: Imperial College Press.

Ordaz, M. A., & Lush, G. B. (2000, March). Machine vision for solar cell characterization. In Machine Vision Applications in Industrial Inspection VIII (Vol. 3966, pp. 238–249). International Society for Optics and Photonics.

Pierdicca, R., Malinverni, E. S., Piccinini, F., Paolanti, M., Felicetti, A., & Zingaretti, P. (2018). Deep convolutional neural network for automatic detection of damaged photovoltaic cells. International Archives of the Photogrammetry, Remote Sensing & Spatial Information Sciences, XLII-2, 893–900.

Qian, X., Zhang, H., Zhang, H., Wu, Y., Diao, Z., Wu, Q. E., et al. (2017). Solar cell surface defects detection based on computer vision. International Journal of Performability Engineering,13(7), 1048.

Silvén, O., Niskanen, M., & Kauppinen, H. (2003). Wood inspection with non-supervised clustering. Machine Vision and Applications,13(5–6), 275–285.

Srivastava, N., Hinton, G., Krizhevsky, A., Sutskever, I., & Salakhutdinov, R. (2014). Dropout: A simple way to prevent neural networks from overfitting. The Journal of Machine Learning Research,15(1), 1929–1958.

Torres, P. J. R., Mercado, E. S., & Rifón, L. A. (2018). Probabilistic Boolean network modeling of an industrial machine. Journal of Intelligent Manufacturing,29(4), 875–890.

Tsai, D. M., Wu, S. C., & Li, W. C. (2012). Defect detection of solar cells in electroluminescence images using Fourier image reconstruction. Solar Energy Materials and Solar Cells,99, 250–262.

Wang, T., Chen, Y., Qiao, M., & Snoussi, H. (2018). A fast and robust convolutional neural network-based defect detection model in product quality control. International Journal of Advanced Manufacturing Technology,94(9–12), 3465–3471.

Weimer, D., Scholz-Reiter, B., & Shpitalni, M. (2016). Design of deep convolutional neural network architectures for automated feature extraction in industrial inspection. CIRP Annals,65(1), 417–420.

**an-Bao, W., Jie, L., Ming-Hai, Y., Wen-**u, H., & Yun-Tao, Q. (2014). Solar cells surface defects detection based on deep learning. Pattern Recognition and Artificial Intelligence,27(6), 517–523.

Yao, M. H., Li, J., & Wang, X. B. (2013). Solar cells surface defects detection using RPCA method. Chinese Journal of Computers,36(9), 1943–1952.

Zhuang, F., Yanzheng, Z., Yang, L., Qixin, C., Mingbo, C., Jun, Z., et al. (2004). Solar cell crack inspection by image processing. In 2004 International Conference on Business of Electronic Product Reliability and Liability (pp. 77–80). IEEE.

Acknowledgements

This work is supported in part by National Natural Science Foundation (NNSF) of China under Grant 61873315, Natural Science Foundation of Hebei Province under Grant F2018202078, Science and Technology Program of Hebei Province under Grant 17211804D, Hebei Province Outstanding Youth Science Foundation F2017202062 and Young Talents Project in Hebei Province under Grant 210003.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, H., Pang, Y., Hu, Q. et al. Solar cell surface defect inspection based on multispectral convolutional neural network. J Intell Manuf 31, 453–468 (2020). https://doi.org/10.1007/s10845-018-1458-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-018-1458-z