Abstract

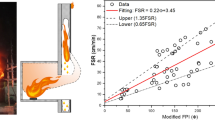

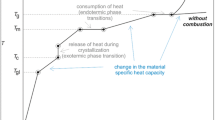

Many fire disasters have occurred on the thermoplastic expanded polystyrene (EPS) external thermal insulation composite systems (ETICS) installed vertically on the building facade. Thus, it is important to understand the reaction-to-fire performance of EPS ETICS and the effect of sample scale, orientation, and masonry cover in fire tests. In this work, both specimens of EPS alone and EPS ETICS with masonry cover are tested under three different scales, (1) 0.01-m2 small-scale cone calorimeter test (ISO 5660-1), (2) 1-m2 intermediate-scale test (ISO 14696), and (3) 7-m2 larger-scale test (JIS A 1310). Results show that the impact of sample orientation is important, because the heated vertical EPS can melt and flow away without ignition, and the masonry cover limits the flow of EPS melts. The peak heat release rate per unit area (pHRRPUA) in the small-scale test doubles that of the large-scale facade test with a vertical flame spread, so that it cannot be simply scaled up. Moreover, the masonry cover on the EPS ETICS can significantly reduce the burning rate and HRR by a factor of 50%, and it is effective from small-scale to large-scale fires. The embedded rock-wool fire barrier inside the EPS ETICS can significantly reduce the vertical flame-spread rate and HRR. This work helps understand the scale-effect of facade fire test and quantifies the effect of masonry cover on lowering facade fire hazards.

Graphic Abstract

Similar content being viewed by others

References

Barreira E, de Freitas VP (2013) Experimental study of the hygrothermal behaviour of external thermal insulation composite systems (ETICS). Build Environ 63:31–39

Nilica R, Harmuth H (2005) Mechanical and fracture mechanical characterization of building materials used for external thermal insulation composite systems. Cement Concrete Res 35:1641–1645

Kolbrecki A (2015) Model of fire spread out on outer building surface. Bull Polish Acad Sci Tech Sci 63:135–144

Khan AA, Lin S, Huang X, Usmani A (2021) Facade fire hazards of bench-scale aluminum composite panel with flame-retardant core. Fire Technol

MacLeod G (2018) The Grenfell tower atrocity. City 22:460–489

Mandilaras I, Atsonios I, Zannis G, Founti M (2014) Thermal performance of a building envelope incorporating ETICS with vacuum insulation panels and EPS. Energy Build 85:654–665

Wang S, Huang X, Chen H, Liu N, Rein G (2015) Ignition of low-density expandable polystyrene foam by a hot particle. Combust Flame 162:4112–4118

Wessies SS, Chang MK, Marr KC, Ezekoye OA (2019) experimental and analytical characterization of firebrand ignition of home insulation materials. Fire Technol 55:1027–1056

Doroudiani S, Omidian H (2010) Environmental, health and safety concerns of decorative mouldings made of expanded polystyrene in buildings. Build Environ 45:647–654

Luo S, ** flow behaviors on the downward flame spread of a wide XPS foam. Fire Technol 55:2055–2086

**e Q, Zhang H, Ye R (2009) Experimental study on melting and flowing behavior of thermoplastics combustion based on a new setup with a T-shape trough. J Hazard Mater 166:1321–1325

Griffin GJ, Bicknell AD, Bradbury GP, White N (2006) Effect of construction method on the fire behavior of sandwich panels with expanded polystyrene cores in room fire tests. J Fire Sci 24:275–294

Xu Q, ** C, Griffin G, Jiang Y (2014) Fire safety evaluation of expanded polystyrene foam by multi-scale methods. J Therm Anal Calorim 115:1651–1660

Yoshioka H, Nishio Y, Tamura M, Yoshida M, Noguchi T, Ohmiya Y et al (2014) Facade tests on fire propagation along combustible exterior wall systems. Fire Sci Technol 33:1–15

Nishio Y, Yoshioka H, Noguchi T, Ando T, Tamura M (2013) Experimental study on fire propagation over combustible exterior facades in Japan. MATEC Web of Conferences: EDP Sciences, p 04001

Mikkola E, Hakkarainen T, Matala A (2013) Fire safety of EPS insulated facades in residential multi-storey buildings. MATEC Web of Conferences: EDP Sciences, p 04002

Mandilaras I, Atsonios I, Zannis G, Founti MJE (2014) Thermal performance of a building envelope incorporating ETICS with vacuum insulation panels and EPS. Buildings 85:654–665

Hofmann A, Kaudelka S, Hauswaldt SJF (2018) Fire safety of FACADES with polystyrene foam insulation. Materials 42:466–474

Hajduković M, Knez N, Knez F, Kolšek J (2017) Fire performance of external thermal insulation composite system (ETICS) facades with expanded polystyrene (EPS) insulation and thin rendering. Fire Technol 53:173–209

Zhou B, Yoshioka H, Noguchi T, Ando T (2018) Experimental study of expanded polystyrene (EPS) External Thermal Insulation Composite Systems (ETICS) masonery facade reaction-to-fire performance. Thermal Science and Engineering Progress 8:83–92

Zhou B, Yoshida M, Noguchi T, Ando T (2020) Experimental study on vertical temperature profile of buoyant window spill plume from intermediate-scale compartments. Fire Mater (in press)

Zhou B, Yoshioka H, Noguchi T, Ando TJF (2018) Effects of opening edge treatment and EPS thickness on EPS external thermal insulation composite systems (ETICS) facade reaction-to-fire performance based on JIS A1310 standard facade fire test method. Materials 42:537–548

Zhou B, Yoshioka H, Noguchi T, Wang K, Huang X (2021) Upward fire spread rate over real-scale EPS ETICS Facades. Fire Technol

Rossi M, Camino G, Luda M (2001) Characterisation of smoke in expanded polystyrene combustion. Polym Degrad Stabil 74:507–512

Bakhtiyari S, Taghi-Akbari L, Barikani M (2010) The effective parameters for reaction-to-fire properties of expanded polystyrene foams in bench scale. Iran Polym J 19:27–37

Huang X, Wang Q, Zhang Y, Yin Y, Sun J (2012) Thickness effect on flame spread characteristics of expanded polystyrene in different environments. J Thermoplast Compos 25:427–438

Xu Q, ** C, Jiang Y (2014) Analysis of the relationship between MCC and thermal analysis results in evaluating flammability of EPS foam. J Therm Anal Calorim 118:687–693

Stec AA, Hull TR (2011) Assessment of the fire toxicity of building insulation materials. Energ Build 43:498–506

Torero JL (2013) Scaling-Up fire. Proc Combust Inst 34:99–124

Kumm M, Söderström J, Lönnermark A (2013) EPS insulated facade fires from a fire and rescue perspective. MATEC Web of Conferences: EDP Sciences, p 05003

Bjegovic D, Pecur IB, Messerschmidt B, Milovanovic B, Alagusic M. Influence of fire barriers on fire performance of facades with combustible insulation. MATEC web of conferences: EDP Sciences, p 05006

ISO 5660-1 (2015) I. Reaction-to-fire tests—heat release, smoke production and mass loss rate—part 1: heat release rate (cone calorimeter method). International Organization for Standardization Geneva, Switzerland

ISO 14696 (2009) I. Reaction-to-fire tests—determination of fire and thermal parameters of materials, products and assemblies using an intermediate-scale calorimeter (ICAL)

JISA1310 (2015) Test method for fire propagation over building facades

Tsai K-C (2009) Orientation effect on cone calorimeter test results to assess fire hazard of materials. J Hazard Mater 172:763–772

Babrauskas V (2016) Heat release rates. Springer, SFPE handbook of fire protection engineering, pp 799–904

Huang X (2018) Critical drip size and blue flame shedding of drip** ignition in fire. Sci Rep 8:16528

Sun P, Lin S, Huang X (2020) Ignition of thin fuel by thermoplastic drips: An experimental study for the drip** ignition theory. Fire Safety J 115:103006

Janssens M, Urbas J (1996) Comparison of small and intermediate scale heat release data. Proceedings of Interflam, p 26–29

Kusch P, Knupp G (2004) Headspace-SPME-GC-MS identification of volatile organic compounds released from expanded polystyrene. J Polym Environ 12:83–87

Acknowledgements

The authors gratefully acknowledge reviewers for the meaningful content discussion. The authors gratefully acknowledge Masamichi Tamura and Yutaka Tanaike from University of Tokyo, Yuhei Nishio, Miki Nakamura, and Yuji Kanda from Tokyo University of Science for preparation of the experiment and the help in the experimental operation, and Zilong Wang from HK PolyU for valuable comments on the analysis.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary file1 (MP4 9537 kb)

Supplementary file2 (MP4 7333 kb)

Rights and permissions

About this article

Cite this article

Zhou, B., Yoshioka, H., Noguchi, T. et al. Fire Performance of EPS ETICS Facade: Effect of Test Scale and Masonry Cover. Fire Technol 59, 95–116 (2023). https://doi.org/10.1007/s10694-021-01195-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10694-021-01195-x