Abstract

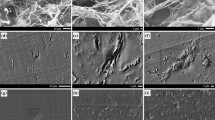

In this study, cellulose nanofibers (CNFs) were treated in an ultrahigh-pressure homogenizer (UHPH) in the thermal imprinting process. After 20 passes, UHPH-treated CNFs with concentrations of 1, 2, and 5 wt% were used to reinforce polyvinyl alcohol (PVA), and PVA/CNF composite films were fabricated by solvent casting. The composite films were subjected to thermal imprinting using a fluoropolymer-treated nickel–phosphorus mold with various line/space micropatterns at different mold temperatures. In addition, the effect of the CNF contents on the viscoelastic behavior, thermomechanical properties, thermal dimensional stability, surface properties, and replication performance of the PVA/CNF composites were investigated. The viscoelastic properties and induced stiffness were improved as a result of the solid-like behavior and CNF network structure, and the coefficient of thermal expansion (CTE) decreased with the increase in the CNF content. The low modulus of the film at thermal imprinting temperatures increased transferability, while the high stiffness, molecular recovery, and low CTE of the composites secured the micropatterns and increased the replication quality of the thermal imprinted PVA/CNF composite films. Results suggested that the addition of CNFs can improve the processability of the thermal imprinting process. Notably, the high replication of films for all micropatterns was observed at a CNF content of 5 wt%. Nevertheless, the narrow micropattern of 5 wt% CNFs could be thermally imprinted at a temperature of less than 120 °C.

Similar content being viewed by others

Data availability

The data and materials presented in this study are available on request from the corresponding author.

References

Azizi Samir MAS, Alloin F, Dufresne A (2005) Review of recent research into cellulosic whiskers, their properties and their application in nanocomposite field. Biomacromol 6:612–626. https://doi.org/10.1021/bm0493685

Biswas SK, Sano H, Shams MI, Yano H (2017) Three-dimensional-moldable nanofiber-reinforced transparent composites with a hierarchically self-assembled “reverse” nacre-like architecture. ACS Appl Mater Interfaces 9:30177–30184. https://doi.org/10.1021/acsami.7b09390

Biswas SK, Tanpichai S, Witayakran S, Yang X, Shams MI, Yano H (2019) Thermally superstable cellulosic-nanorod-reinforced transparent substrates featuring microscale surface patterns. ACS Nano 13:2015–2023. https://doi.org/10.1021/acsnano.8b08477

Castro C, Vesterinen A, Zuluaga R, Caro G, Filpponen I, Rojas OJ, Kortaberria G, Gañán P (2014) In situ production of nanocomposites of poly(vinyl alcohol) and cellulose nanofibrils from Gluconacetobacter bacteria: effect of chemical crosslinking. Cellulose 21:1745–1756. https://doi.org/10.1007/s10570-014-0170-1

Eichhorn SJ, Dufresne A, Aranguren M, Marcovich NE, Capadona JR, Rowan SJ, Weder C, Thielemans W, Roman M, Renneckar S, Gindl W, Veigel S, Keckes J, Yano H, Abe K, Nogi M, Nakagaito AN, Mangalam A, Simonsen J, Benight AS, Bismarck A, Berglund LA, Peijs T (2010) Review: current international research into cellulose nanofibres and nanocomposites. J Mater Sci 45:1–33. https://doi.org/10.1007/s10853-009-3874-0

Falah Toosi S, Moradi S, Ebrahimi M, Hatzikiriakos SG (2016) Microfabrication of polymeric surfaces with extreme wettability using hot embossing. Appl Surf Sci 378:426–434. https://doi.org/10.1016/j.apsusc.2016.03.116

Farooq A, Patoary MK, Zhang M, Mussana H, Li M, Naeem MA, Mushtaq M, Farooq A, Liu L (2020) Cellulose from sources to nanocellulose and an overview of synthesis and properties of nanocellulose/zinc oxide nanocomposite materials. Int J Biol Macromol 154:1050–1073. https://doi.org/10.1016/j.ijbiomac.2020.03.163

Guan QF, Yang HB, Han ZM, Zhou LC, Zhu YB, Ling ZC, Jiang HB, Wang PF, Ma T, Wu HA, Yu SH (2020) Lightweight, tough, and sustainable cellulose nanofiber-derived bulk structural materials with low thermal expansion coefficient. Sci Adv 6:eaaz1114. https://doi.org/10.1126/sciadv.aaz1114

Hata T, Kitazaki Y, Saito T (1987) Estimation of the surface energy of polymer solids. J Adhes 21:177–194. https://doi.org/10.1080/00218468708074968

Heyderman LJ, Schift H, David C, Gobrecht J, Schweizer T (2000) Flow behaviour of thin polymer films used for hot embossing lithography. Microelectron Eng 54:229–245. https://doi.org/10.1016/S0167-9317(00)00414-7

Hirai Y, Yoshida S, Okamoto A, Tanaka Y, Endo M, Irie S, Nakagawa H, Sasago M (2001) Mold surface treatment for imprint lithography. J Photopolym Sci Technol 14:457–462. https://doi.org/10.2494/photopolymer.14.457

Hirai Y, Yoshida S, Takagi N (2003) Defect analysis in thermal nanoimprint lithography. J Vac Sci Technol B 21:2765–2770. https://doi.org/10.1116/1.1629289

Hirai Y (2010) Process physics in thermal nanoimprint. J Jpn Soc Precis Eng 76:143–147

Horiba A, Yasuda M, Kawata H, Okada M, Matsui S, Hirai Y (2012) Impact of resist shrinkage and its correction in nanoimprint lithography. Jpn J Appl Phys 51:06FJ06

Ishihara K, Fujita M, Matsubara I, Asano T, Noda S, Ohata H, Hirasawa A, Nakada H, Shimoji N (2007) Organic light-emitting diodes with photonic crystals on glass substrate fabricated by nanoimprint lithography. Appl Phys Lett. https://doi.org/10.1063/1.2713237

Isogai A (2018) Development of completely dispersed cellulose nanofibers. Proc Jpn Acad Ser B Phys Biol Sci 94:161–179. https://doi.org/10.2183/pjab.94.012

Isogai A (2020) Cellulose nanofibers: recent progress and future prospects. J Fiber Sci Technol 76:310–326. https://doi.org/10.2115/fiberst.2020-0039

Isogai A, Bergström L (2018) Preparation of cellulose nanofibers using green and sustainable chemistry. Curr Opin Green Sustain Chem 12:15–21. https://doi.org/10.1016/j.cogsc.2018.04.008

Ito A, Semba T, Kitagawa K, Okumura H, Yano H (2019) Cell morphologies and mechanical properties of cellulose nanofiber reinforced polypropylene foams. J Cell Plast 55:385–400. https://doi.org/10.1177/0021955X19841049

Jeon S, Kang J, Park H, Kim J, Youn JR, Shim J, Jeong J, Choi D, Kim K, Altun AO, Kim S, Lee Y (2008) Ultraviolet nanoimprinted polymer nanostructure for organic light emitting diode application. Appl Phys Lett. https://doi.org/10.1063/1.2939554

Jonoobi M, Harun J, Mathew AP, Oksman K (2010) Mechanical properties of cellulose nanofiber (CNF) reinforced polylactic acid (PLA) prepared by twin screw extrusion. Compos Sci Technol 70:1742–1747. https://doi.org/10.1016/j.compscitech.2010.07.005

Joy J, Jose C, Varanasi SB, Mathew PL, Thomas S, Pilla S (2016) Preparation and characterization of poly(butylene succinate) bionanocomposites reinforced with cellulose nanofiber extracted from Helicteres isora Plant. J Renew Mater 4:351–364. https://doi.org/10.7569/JRM.2016.634128

Kawata H, Yasuda M, Hirai Y (2016) Impact of wafer deformation on pattern fabrication for thermal nanoimprint lithography. J Photopolym Sci Technol 29:215–219. https://doi.org/10.2494/photopolymer.29.215

Kim JA, Park SC, Alle M, Lee SJ, Kim J (2021) Magnesium ascorbyl phosphate loaded in dissolving stiff microneedles containing cellulose nanofiber. J Drug Deliv Sci Technol 63:102439. https://doi.org/10.1016/j.jddst.2021.102439

Kim J-H, Shim BS, Kim HS, Lee Y, Min S, Jang D, Abas Z, Kim J (2015) Review of nanocellulose for sustainable future materials. Int J Precis Eng Manuf Green Technol 2:197–213. https://doi.org/10.1007/s40684-015-0024-9

Kim JK, Cho HS, Jung HS, Lim K, Kim KB, Choi DG, Jeong JH, Suh KY (2012) Effect of surface tension and coefficient of thermal expansion in 30 nm scale nanoimprinting with two flexible polymer molds. Nanotechnology 23:235303. https://doi.org/10.1088/0957-4484/23/23/235303

Kuroda S, Mizutani A, Ito H (2019) Influence of talc and rubber contents on surface replication of polypropylene injection molding application to automotive plastics. J Polym Eng 39:300–308. https://doi.org/10.1515/polyeng-2018-0251

Kuroda S, Mizutani A, Ito H (2020) Effect of talc size on surface roughness and glossiness of polypropylene injection molding application to automotive plastics. Polym Eng Sci 60:132–139. https://doi.org/10.1002/pen.25266

Kurose T, Shishido H, Ishigami A, Nemoto A, Ito H (2020) Fabrication of high-resolution conductive patterns on a thermally imprinted polyetherimide film by the capillary flow of conductive ink. Microsyst Technol 26:1981–1986. https://doi.org/10.1007/s00542-020-04749-1

Lee JH, Park SH, Kim SH, Ito H (2020) Replication and surface properties of micro injection molded PLA/MWCNT nanocomposites. Polym Test 83:106321. https://doi.org/10.1016/j.polymertesting.2019.106321

Lhernould MS, Deleers M, Delchambre A (2015) Hollow polymer microneedles array resistance and insertion tests. Int J Pharm 480:152–157. https://doi.org/10.1016/j.ijpharm.2015.01.019

Li M, Chen Y, Luo W, Cheng X (2021) Interfacial interactions during demolding in nanoimprint lithography. Micromachines 12:349. https://doi.org/10.3390/mi12040349

Lu J, Wang T, Drzal LT (2008) Preparation and properties of microfibrillated cellulose polyvinyl alcohol composite materials. Compos A 39:738–746. https://doi.org/10.1016/j.compositesa.2008.02.003

Meree CE, Schueneman GT, Meredith JC, Shofner ML (2016) Rheological behavior of highly loaded cellulose nanocrystal/poly(vinyl alcohol) composite suspensions. Cellulose 23:3001–3012. https://doi.org/10.1007/s10570-016-1003-1

Morita A, Matsuba G, Fujimoto M (2021) Evaluation of hydrophilic cellulose nanofiber dispersions in a hydrophobic isotactic polypropylene composite. J Appl Polym Sci 138:49896. https://doi.org/10.1002/app.49896

Muanchan P, Kurose T, Ito H (2019a) Replication and thermal properties of one-dimensional composite nanostructures with enhanced mechanical robustness. J Electrochem Soc 166:B3282–B3289. https://doi.org/10.1149/2.0391909jes

Muanchan P, Kurose T, Ito H (2019b) Replication of mesoscale pore one-dimensional nanostructures: surface-induced phase separation of polystyrene/poly(vinyl alcohol) (PS/PVA) blends. Polymers 11:1039. https://doi.org/10.3390/polym11061039

Muanchan P, Suzuki S, Kyotani T, Ito H (2017) One-dimensional polymer nanofiber arrays with high aspect ratio obtained by thermal nanoimprint method. Polym Eng Sci 57:214–223. https://doi.org/10.1002/pen.24403

Nakagaito AN, Yano H (2008) The effect of fiber content on the mechanical and thermal expansion properties of biocomposites based on microfibrillated cellulose. Cellulose 15:555–559. https://doi.org/10.1007/s10570-008-9212-x

Nishikura N, Kawata H, Hirai Y (2013) Approach for high aspect ratio pattern transfer by nanoimprint lithography using mixture polymers of molecular weights. J Photopolym Sci Technol 26:97–103. https://doi.org/10.2494/photopolymer.26.97

Nishiyama Y (2009) Structure and properties of the cellulose microfibril. J Wood Sci 55:241–249. https://doi.org/10.1007/s10086-009-1029-1

Okahisa Y, Yoshida A, Miyaguchi S, Yano H (2009) Optically transparent wood–cellulose nanocomposite as a base substrate for flexible organic light-emitting diode displays. Compos Sci Technol 69:1958–1961. https://doi.org/10.1016/j.compscitech.2009.04.017

Oishi Y, Nakaya M, Matsui E, Hotta A (2015) Structural and mechanical properties of cellulose composites made of isolated cellulose nanofibers and poly(vinyl alcohol). Compos A 73:72–79. https://doi.org/10.1016/j.compositesa.2015.02.026

Peresin MS, Habibi Y, Zoppe JO, Pawlak JJ, Rojas OJ (2010) Nanofiber composites of polyvinyl alcohol and cellulose nanocrystals: manufacture and characterization. Biomacromol 11:674–681. https://doi.org/10.1021/bm901254n

Prado-Martínez C, Sutton P, Mombrini I, Kamtsikakis A, Meesorn W, Weder C, Steiner U, Gunkel I (2023) Cellulose nanofiber-reinforced solid polymer electrolytes with high ionic conductivity for lithium batteries. J Mater Chem A Mater 11:9521–9529. https://doi.org/10.1039/d3ta00380a

Prakash Menon M, Selvakumar R, Suresh Kumar P, Ramakrishna S (2017) Extraction and modification of cellulose nanofibers derived from biomass for environmental application. RSC Adv 7:42750–42773. https://doi.org/10.1039/C7RA06713E

Ramezani Kakroodi A, Cheng S, Sain M, Asiri A (2014) Mechanical, thermal, and morphological properties of nanocomposites based on polyvinyl alcohol and cellulose nanofiber from Aloe vera rind. J Nanomater 2014:903498. https://doi.org/10.1155/2014/903498

Salehpour S, Rafieian F, Jonoobi M, Oksman K (2018) Effects of molding temperature, pressure and time on polyvinyl alcohol nanocomposites properties produced by freeze drying technique. Ind Crops Prod 121:1–9. https://doi.org/10.1016/j.indcrop.2018.04.079

Scheer H-C (1998) Problems of the nanoimprinting technique for nanometer scale pattern definition. J Vac Sci Technol B 16:3917–3921. https://doi.org/10.1116/1.590436

Scheer H-C, Bogdanski N, Wissen M, Möllenbeck S (2007) Impact of glass temperature for thermal nanoimprint. J Vac Sci Technol B. https://doi.org/10.1116/1.2811718

Scheer H-C, Bogdanski N, Wissen M, Möllenbeck S (2008) Imprintability of polymers for thermal nanoimprint. Microelectron Eng 85:890–896. https://doi.org/10.1016/j.mee.2007.12.025

Semba T, Ito A, Kitagawa K, Nakatani T, Yano H, Sato A (2014) Thermoplastic composites of polyamide-12 reinforced by cellulose nanofibers with cationic surface modification. J Appl Polym Sci. https://doi.org/10.1002/app.40920

Semba T, Taguma K, Tawara M, Ito A, Kitagawa K, Sato A, Yano H (2016) Biocomposites composed of polyamide 11 and cellulose nanofibers pretreated with a cationic reagents. Nihon Reoroji Gakkaishi 45:39–47. https://doi.org/10.1678/rheology.45.39

Shibata M, Tanabe T, Kimoto Y, Kawata H, Hirai Y (2008) Study on polymer and process design in thermal nanoimprint lithography. J Photopolym Sci Technol 21:601–606. https://doi.org/10.2494/photopolymer.21.601

Shiotsu T, Nishikura N, Yasuda M, Kawata H, Hirai Y (2013) Simulation study on the template release mechanism and damage estimation for various release methods in nanoimprint lithography. J Vac Sci Technol B 31:06FB07. https://doi.org/10.1116/1.4832215

Sun X, Wu Q, Zhang X, Ren S, Lei T, Li W, Xu G, Zhang Q (2018) Nanocellulose films with combined cellulose nanofibers and nanocrystals: tailored thermal, optical and mechanical properties. Cellulose 25:1103–1115. https://doi.org/10.1007/s10570-017-1627-9

Tochino T, Uemura K, Michalowski M, Fujii K, Yasuda M, Kawata H, Rymuza Z, Hirai Y (2015) Computational study of the effect of side wall quality of the template on release force in nanoimprint lithography. Jpn J Appl Phys 54:06FM06. https://doi.org/10.7567/JJAP.54.06FM06

Ueda T, Ishigami A, Thumsorn S, Kurose T, Kobayashi Y, Ito H (2022) Structural, rheological, and mechanical properties of polyvinyl alcohol composites reinforced with cellulose nanofiber treated by ultrahigh-pressure homogenizer. Mater Today Commun 33:104316. https://doi.org/10.1016/j.mtcomm.2022.104316

Wu Y, Tang Q, Yang F, Xu L, Wang X, Zhang J (2019) Mechanical and thermal properties of rice straw cellulose nanofibrils-enhanced polyvinyl alcohol films using freezing-and-thawing cycle method. Cellulose 26:3193–3204. https://doi.org/10.1007/s10570-019-02310-6

Yokoi H, Han X, Takahashi T, Kim WK (2006) Effects of molding conditions on transcription molding of microscale prism patterns using ultra-high-speed injection molding. Polym Eng Sci 46:1140–1146. https://doi.org/10.1002/pen.20519

Acknowledgments

The authors would like to thank Mr. Yatsuzuka from KOS21 Co., Ltd., Japan, who prepared the cellulose nanofiber suspension, and Enago (www.enago.jp) for providing English language editing support. The authors also thank the Japan Science and Technology Agency in the Public Engagement on the Establishment of University Fellowships toward the Creation of Science Technology Innovation, Grant Number JPMJFS2104.

Funding

This research was supported by Japan Science and Technology Agency in the Public Engagement on the Establishment of University Fellowships toward the Creation of Science Technology Innovation, Grant Number JPMJFS2104.

Author information

Authors and Affiliations

Contributions

Conceptualization, HI; Methodology, TU, AI, and YK; Formal analysis and investigation, TU, AI, and AN; Writing—original draft preparation, TU; Writing—review and editing, ST and HI; Project administration, HI; All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ueda, T., Nemoto, A., Ishigami, A. et al. Surface replication and characterization of ultrahigh-pressure homogenizer treated cellulose nanofiber-reinforced polyvinyl alcohol composites by thermal imprinting. Cellulose 30, 10983–10998 (2023). https://doi.org/10.1007/s10570-023-05557-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-023-05557-2